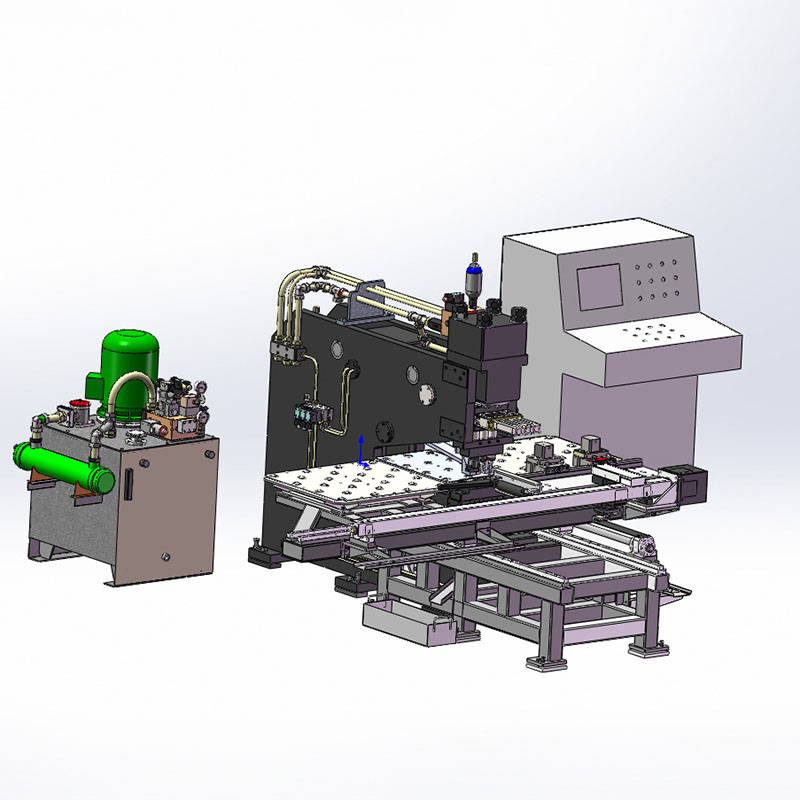

Wholesale CNC Machine Milling - BL3635 Cnc Angle Steel Drilling Marking Machine – FIN CNC

Wholesale CNC Machine Milling - BL3635 Cnc Angle Steel Drilling Marking Machine – FIN CNC Detail:

Product Parameters

| NO. | ||

| 1 | Angle size | 140×140×10 – 360×360×35 |

| 2 | Range of stadia | 50 ~ 330(stepless) |

| 3 | The quantity of punching row per side | arbitrariness |

| 4 | Quantity of drilling spindle per side | 3 |

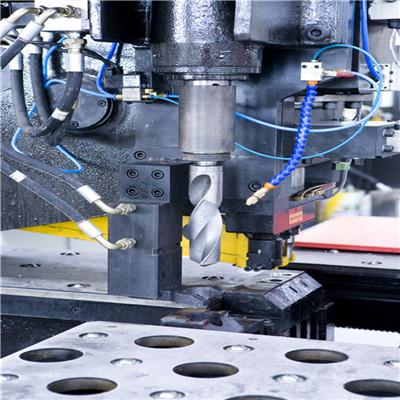

| 5 | Range of drilling diameter(high-speed steel twist drill) | φ17.5 ~ φ40mm |

| 6 | Motor power of drilling spindle | 2×5.5 |

| 7 | Rotation speed of spindle(r/min) | 180 ~ 560(stepless adjustment) |

| 8 | Nominal marking force | 1200Kn |

| 9 | Feeding speed(mm/min) | 20 ~ 280 |

| 10 | Quantity of CNC axis | 3 |

| 11 | Max. length of material | 12m |

| 12 | Angle feeding speed (m/min) | 40 |

| 13 | Quantity of character group | 1 group |

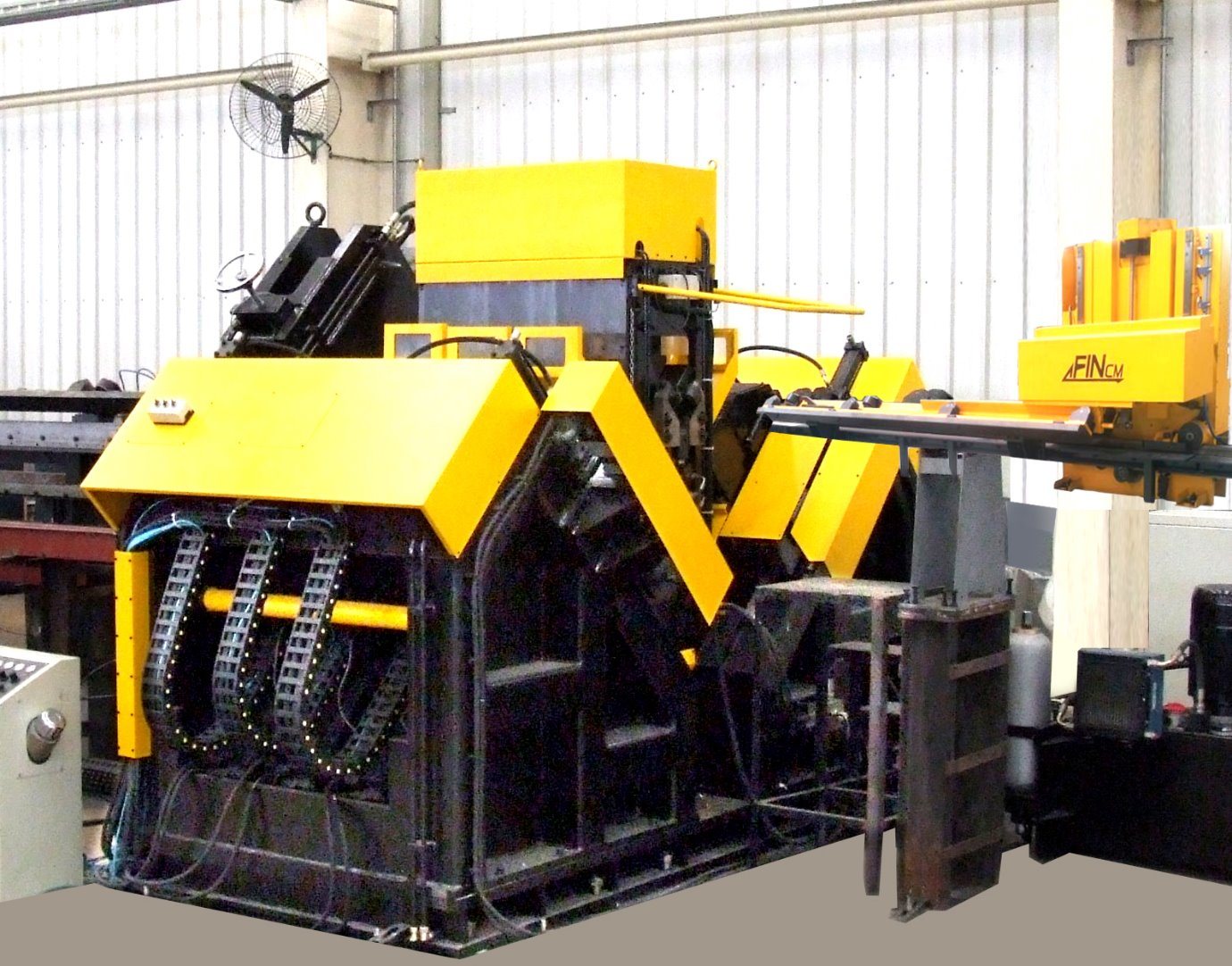

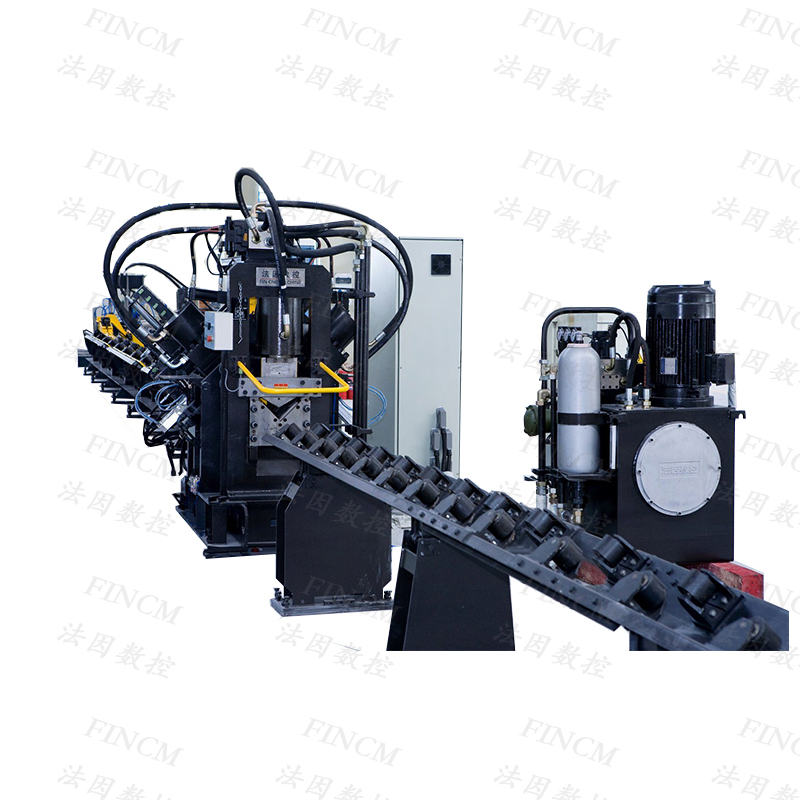

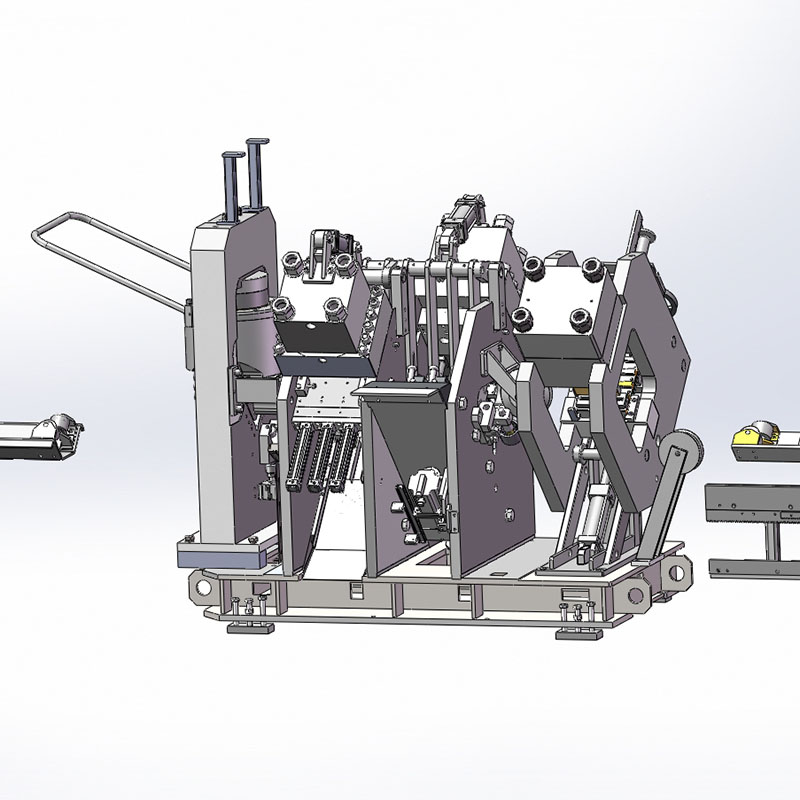

Details And Advantages

1、High degree of automation. The production line is equipped with automatic feeding device and transverse feeding conveyor.

2、All the holes and marking numbers/character on the angle material can be processed by the production line at one time automatically.

3、The positioning precision of hole making is very high.

4、Drilling efficiency and drilling quality are high. The drilling unit is equipped with six groups of CNC drilling power .

5 、There are three drilling groups on each side of the angle material.

6、 The drilling spindle is equipped with disc spring automatic broach mechanism.

7、 The handle is very convenient.

8 、MQL (minimum quantities of lubricant) cooling system is the most advanced cooling system in the world.

Key Outsourced Component List

|

No. |

Name |

Brand |

Country |

|

1 |

AC Servo motor |

Panasonic / Siemens |

Japan |

|

2 |

Orientation module |

Yokogawa |

Japan |

|

3 |

Program controller |

Yokogawa |

Japan |

|

4 |

Proximity switch |

AUTONICS |

Korea |

|

5 |

Electromagnetic valve |

ATOS/Yuken |

Italy/ Taiwan China |

|

6 |

relief valve |

ATOS/Yuken |

Italy/ Taiwan China |

|

7 |

Pressure reducing valve |

ATOS/Yuken |

Italy/ Taiwan China |

|

8 |

Guide |

HIWIN/CSK |

Taiwan China |

|

9 |

Pneumatic combined unit |

SMC/CKD |

Japan |

|

10 |

Air valve |

AIRTAC |

Taiwan China |

|

11 |

Cylinder |

AIRTAC |

Taiwan China |

Note: The above is our fixed supplier. If the supplier can not supply the components in case of any special matter, we will adopt the components with the same level, but the quality is no worse than the above.

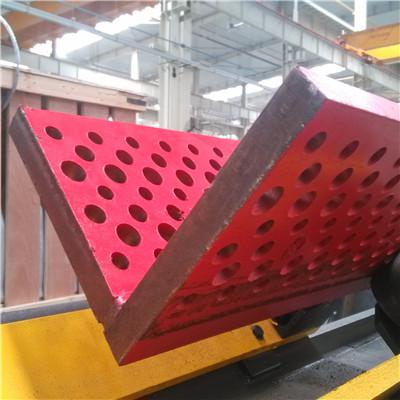

Product detail pictures:

Related Product Guide:

Our progress depends about the advanced products ,fantastic talents and continuously strengthened technology forces for Wholesale CNC Machine Milling - BL3635 Cnc Angle Steel Drilling Marking Machine – FIN CNC , The product will supply to all over the world, such as: Islamabad, Bolivia, Monaco, Excellent quality comes from our adherence to every detail, and customer satisfaction comes from our sincere dedication. Relying on advanced technology and industry reputation of good cooperation, we try our best to provide more quality products and services to our customers, and all of us are willing to strengthen exchanges with domestic and foreign customers and sincere cooperation, to build a better future.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.