Truck And Special Machine Products

-

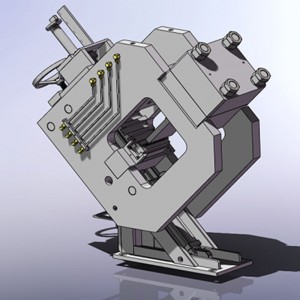

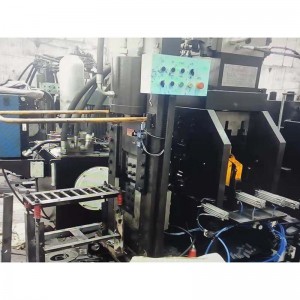

PUL CNC 3-Sides Punching Machine for U-Beams of Truck Chassis

a) It’s truck/lorry U Beam CNC Punching Machine, popularly used for automobile manufacture industry.

b) This machine can be used for 3-sides CNC punching of automobile longitudinal U beam with equal cross section of the truck/lorry.

c) The machine has the characteristics of high processing precision, fast punching speed and high production efficiency.

d) The whole process is fully automatic and flexible, which can adapt to the mass production of longitudinal beam, and can be used to develop new products with small batch and many kinds of production.

e) The production preparation time is short, which can greatly improve the product quality and production efficiency of the automobile frame.

-

S8F Frame Double Spindle CNC Drilling Machine

The S8F frame double-spindle CNC machine is a special equipment for machining the balance suspension hole of the heavy truck frame. The machine is installed on the frame assembly line, which can meet the production cycle of the production line, is convenient to use, and can greatly improve production efficiency and processing quality.

-

PPL1255 CNC Punching Machine for Plates Used for Truck Chassis Beams

The CNC punching production line of automobile longitudinal beam can be used for CNC punching of automobile longitudinal beam. It can process not only rectangular flat beam, but also special-shaped flat beam.

This production line has the characteristics of high machining precision, high punching speed and high production efficiency.

The production preparation time is short, which can greatly improve the product quality and production efficiency of automobile frame.

-

PUL14 CNC U Channel and Flat Bar Punching Shearing Marking Machine

It is mainly used for customers to manufacture flat bar and U channel steel material, and complete punching holes, cutting to length and marking on flat bar and U channel steel. Simple operation and high production efficiency.

This machine mainly serves for power transmission tower manufacture and steel structure fabrication.

-

PPJ153A CNC Flat bar Hydraulic Punching and Shearing Production line Machine

CNC Flat Bar hydraulic punching and shearing production line is used for punching and cutting to length for flat bars.

It has high work efficiency and automation. It is especially suitable for various types of mass production processing and is popularly used in power transmission line towers manufacture and car parking garages fabrication and other industries.

-

GHQ Angle Heating & Bending Machine

Angle bending machine is mainly used for angle profile’s bending and plate’s bending. It is suitable for power transmission line tower, tele-communication tower, power station fittings, steel structure, storage shelf and other industries.

-

TD Series-2 CNC Drilling Machine for Header Tube

This Machine is mainly used to drill tube holes on header tube which used for boiler industry.

It also could use special tools to make welding groove, greatly increase the hole’s precision and drilling efficiency.

-

TD Series-1 CNC Drilling Machine for Header Tube

Gantry header pipe high-speed CNC drilling machine is mainly used for drilling and welding groove processing of header pipe in boiler industry.

It adopts internal cooling carbide tool for high-speed drilling processing. It can not only use standard tool, but also use special combination tool completes the processing of through hole and basin hole at one time.

-

HD1715D-3 Drum horizontal three-spindle CNC drilling machine

HD1715D/3-type horizontal three-spindle CNC Boiler Drum Drilling machine is mainly used for drilling holes on drums, shells of boilers, heat exchangers or pressure vessels. It’s popular machine widely used for pressure vessel fabrication industry (boilers, heat exchangers, etc.)

The drill bit is automatically cooled and chips are automatically removed, making the operation extremely convenient.

-

RS25 25m CNC Rail Sawing Machine

RS25 CNC rail sawing production line is mainly used for accurate sawing and blanking of rail with maximum length of 25m, with automatic loading and unloading function.

The production line reduces the labor time and labor intensity, and improves the production efficiency.

-

RDS13 CNC Rail Saw and Drill Combined Production Line

This machine is mainly used for sawing and drilling of railway rails, as well as for drilling of alloy steel core rails and alloy steel inserts, and has a chamfering function.

It’s mainly used for railway fabrication in transportation manufacture industry. It can greatly reduce man power cost and improve productivity.

-

RDL25B-2 CNC Rail Drilling Machine

This machine is mainly used for drilling and chamfering of rail waist of various rail parts of railway turnout.

It uses forming cutter for drilling and chamfering in front, and chamfering head on the reverse side. It has loading and unloading functions.

The machine has high flexibility, can achieve semi-automatic production.