TD Series-2 CNC Drilling Machine for Header Tube

| Dimension and machining accuracy of header pipe | Processing materials | Carbon steel, SA-335P91, etc. |

| Outer diameter of processing header | φ190-φ1020mm | |

| Borehole diameter | φ20-φ60mm | |

| Maximum diameter of Counter bore | φ120mm | |

| Maximum rotation diameter of material | φ1200mm | |

| Maximum drilling wall thickness | 160mm | |

| Maximum length of processing header | 24m | |

| Minimum hole end distance | 200mm | |

| Maximum weight of material | 30t | |

| CNC dividing head | Quantity | 1 |

| Slewing speed | 0-4r/min(CNC) | |

| Diameter of electric self centering chuck | φ1000mm | |

| Vertical feed rate mode | Inching | |

| Drilling head and its vertical slide | Drilling spindle taper hole | BT50 |

| Number of working heads | 3 | |

| Spindle servo motor power | 37Kw | |

| Maximum torque of spindle | 800NM | |

| Spindle speed | 100-4000 rpm, 2500 rpm for continuous and stable operation | |

| Maximum axial moving speed of drilling head | 5000mm/min | |

| Lateral movement speed of drilling head | 1000mm/min | |

| Spindle ram stroke | 400mm | |

| Distance between spindle end face and axis A | 300~1000mm(plus skateboard travel) | |

| Shaft spacing of 1,3 drilling head | 1400mm-1600mm(CNC adjustable) | |

| Big skateboard stroke | 300mm | |

| Moving driving mode of large skateboard | Motor and screw | |

| other | Number of CNC systems | 1set |

| Number of CNC axes | 9+3(9 feed shafts, 3 spindles) | |

| Testing organization | 3 sets | |

| Press cylinder | 3 sets | |

| Fixed support | 1set | |

| Follow up lower support | 1set | |

| End support | 1set |

1. The total length of the base is about 31m, which is made up of four sections. The base is welded and has good rigidity and stability after heat aging treatment

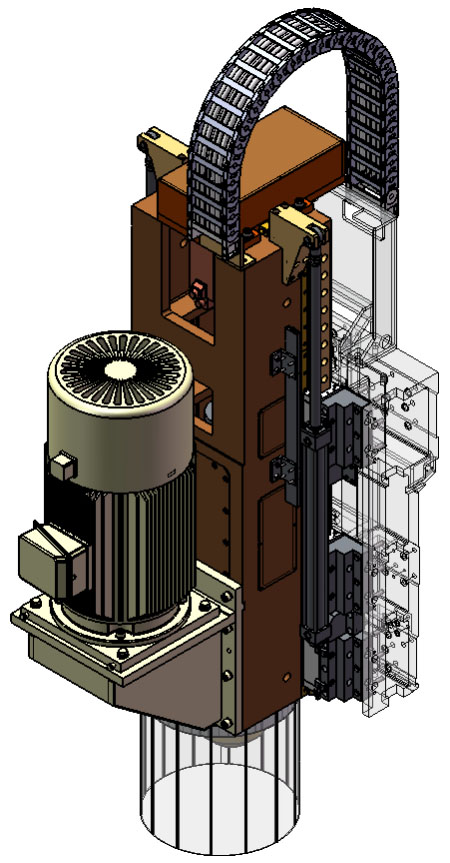

2. The gantry longitudinal movement (x-axis) is guided by four high bearing capacity linear rolling guide pairs fixed on the bed, driven by dual drive, so that the gantry can be locked on the bed, enhancing the stability of the gantry during processing.

3. The CNC indexing head is fixed at one end of the machine base. The precision rotary bearing is adopted to realize the CNC indexing by AC servo motor through precision planetary reducer.

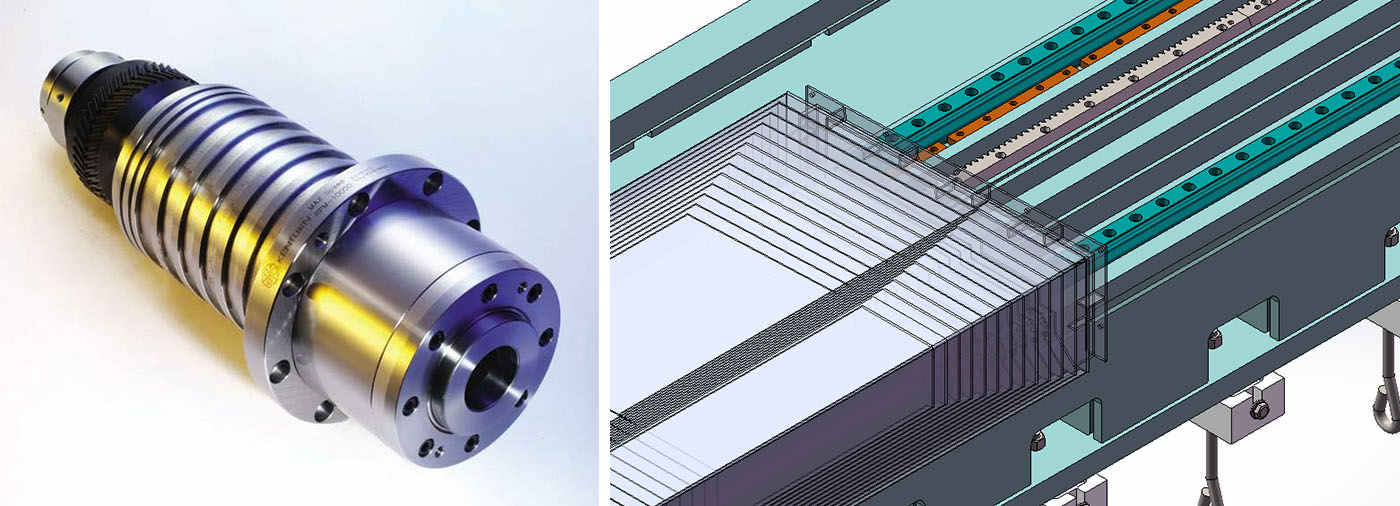

4. The drilling head is driven by the spindle servo motor through dual speed reducer and belt speed reduction. The drilling head is of ram type structure and adopts Taiwan precision spindle (internal cooling).

5. The axial feed adopts rectangular guide and AC servo motor to drive ball screw pair to realize fast forward / work forward / stop (delay) / fast backward and other actions.

6. The machin is equipped with a cooling system, with internal cooling and external cooling functions, which can provide internal cooling for the tool to ensure the drilling performance and service life of the bit. The external cooling is mainly used to remove the iron chips on the upper surface of the material, so as not to affect the detection accuracy of the detection system

|

NO |

Name |

Brand |

Country |

|

1 |

Linear guide rail |

HIWIN/PMI |

Taiwan, China |

|

2 |

Linear guide at slide plate and power head (at slide plate and power head) |

Schneeberger Rexrorh |

Switzerland, Germany |

|

3 |

Ball screw |

I+F/NEEF |

Germany |

|

4 |

CNC system |

Siemens |

Germany |

|

5 |

Feed servo motor |

Siemens |

Germany |

|

6 |

Spindle servo motor |

Siemens |

Germany |

|

7 |

Rack |

ATLANTA/ WMH Herg |

Germany |

|

8 |

Precision reducer |

ZF/BF |

Germany / Italy |

|

9 |

Hydraulic valve |

ATOS |

Italy |

|

10 |

Oil pump |

Justmark |

Taiwan, China |

|

11 |

Drag chain |

Kabelschelp/Igus |

Germany |

|

12 |

Automatic lubrication system |

Herg |

Japan |

|

13 |

Button, indicator light and other main electrical components |

Schneider |

France |

Note: The above is our standard supplier. It's subject to be replaced by same quality components of other brand if the above supplier can't supply the components in case of any special matter.

Company Brief Profile  Factory Information

Factory Information  Annual Production Capacity

Annual Production Capacity  Trade Ability

Trade Ability