PP103B CNC Steel Construction Plate Hydraulic Punching Marking Machine

| NO. |

Item |

Parameters | |

| 1 | Max punching force | 1000KN | |

| 2 | Max plate dimension | 775*1500mm | |

| 3 | The plate thickness | 5-25mm | |

| 4 | Max punching diameter | φ25.5mm(16Mn,20mm thickness、Q235,25mm thickness) | |

| 5 | Number of modules | 3 | |

| 6 | The minimum distance from the hole to the edge | 25mm | |

| 7 | Max marking force | 800KN | |

| 8 | Number of characters and size | 10(14*10mm) | |

| 9 |

The Precision |

Angle steel joint connecting plate with any hole spacing | Vertical ±0.5mm, horizontal ±0.5mm |

| Hole centerline sloped | On the plate thickness ≤0.03t, and ≤2mm | ||

| Junction plate | Any two sets of hole spacing ±1.0mm,

steel plate edge distance: ±1.0mm |

||

| 10 | Hydraulic pump motor power | 15KW | |

| 11 | X, Y axis servo motor power | 2*2KW | |

| 12 | Required compressed air pressure * displacement | 0.5MPa*0.1m3/min | |

1. With three die positions, three sets of punching dies can be installed to punch three different diameter holes on the workpiece;

You can also only install two sets of punching dies and one character box, which can punch out holes of two different diameters.

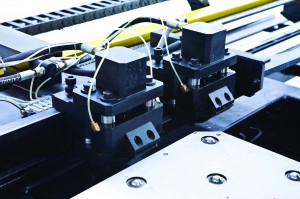

2. The machine has two CNC axes: X axis is the left and right movement of the clamp, Y axis is the front and rear movement of the clamp.The moving, high-rigid CNC worktable ensures the reliability and precision of feeding.

3. The X and Y transmission shafts use precision ball screws to ensure transmission accuracy.

4. Both X and Y axes use precision linear guide rails, with large load, high precision and long service life of the guide rails.

And can maintain the high precision of the machine tool for a long time.

5. The combination of centralized lubrication and distributed lubrication is used to lubricate the machine tool, so that the machine tool can be lubricated.Always in good working order.

6. The CNC worktable for moving the plate is directly fixed on the foundation, and the worktable is equipped with a universal conveyor

Ball, small resistance, low noise and easy maintenance when the plate moves.

7.The plate is clamped by two powerful hydraulic clamps and moves quickly for positioning. The clamp can be adjusted with the plate.

Ups and downs, up and down. The distance between the two clamps can be adjusted arbitrarily according to the length of the plate clamping side.

8. The pumps, valves and other parts of the hydraulic system are all brand-name products, so that the structure of the hydraulic power system is tight.Compact, firm and durable, stable stamping, sufficient power, ensure the dynamic performance of the machine tool, improve the machine toolThe reliability of the bed.

9.The plate processing time is short, the positioning is fast, the operation is simple, the floor space is small, and the production efficiency is high.

|

NO. |

Item |

Brand |

Place of origin |

|

1 |

AC Servo Motor |

DETAL |

Taiwan(China) |

|

2 |

PLC |

DETAL |

|

|

3 |

Solenoid unloading valve |

ATOS/YUKEN |

Italy/Taiwan(China) |

|

4 |

Relief valve |

ATOS/YUKEN |

|

|

5 |

Solenoid reversing valve |

JUSTMARK |

Taiwan(China) |

|

6 |

Junction Plate |

SMC/CKD |

Japan |

|

7 |

Air valve |

SMC/CKD |

|

|

8 |

Air cylinder |

SMC/CKD |

|

|

9 |

Doublet |

AIRTAC |

Taiwan(China) |

|

10 |

Computer |

Lenovo |

China |

Note: The above is our fixed supplier. It’s subject to be replaced by same quality components of other brand if the above supplier can’t supply the components in case of any special matter.

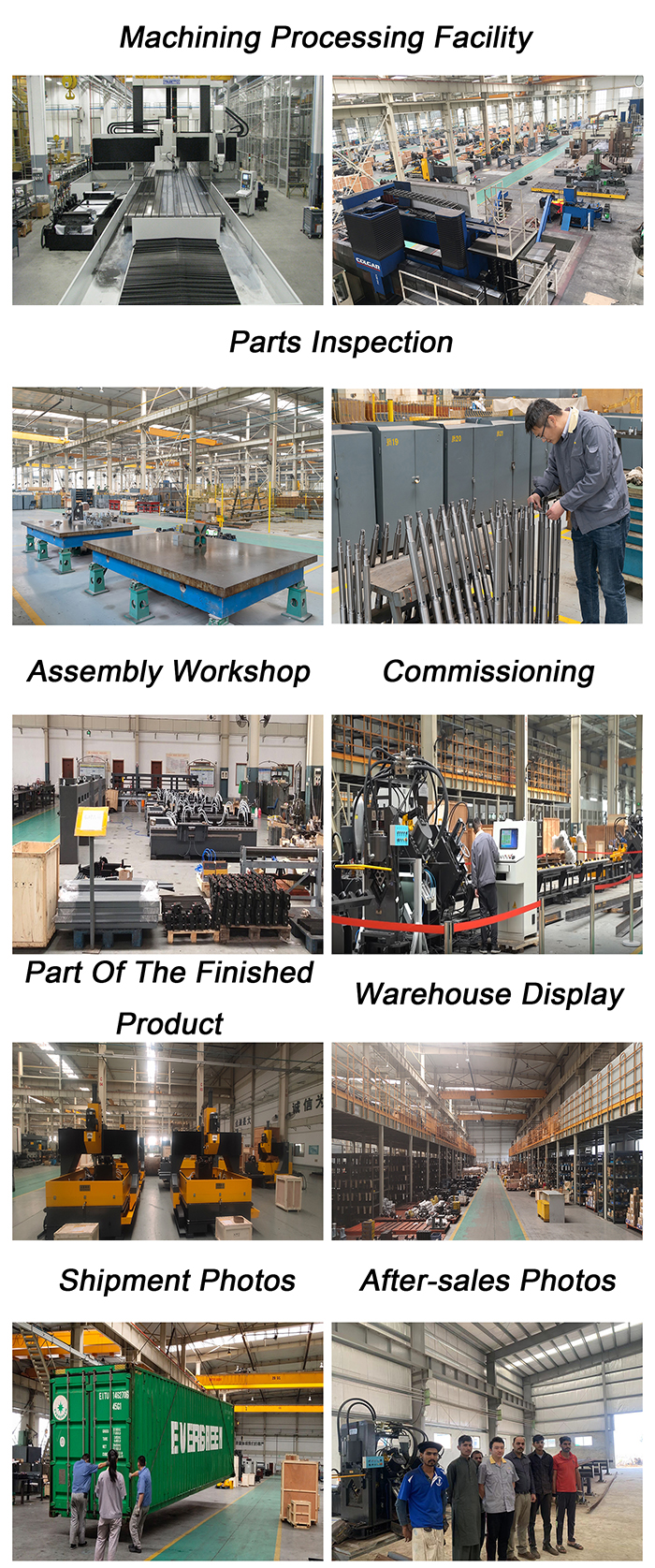

Our company makes CNC machines for processing various steel profiles material, such as Angle bar profiles, H beams/U channels and steel plates.

|

Business Type |

Manufacturer, Trading Company |

Country / Region |

Shandong, China |

|

Main Products |

Ownership |

Private Owner |

|

|

Total Employees |

201 – 300 People |

Total Annual Revenue |

Confidential |

|

Year Established |

1998 |

Certifications(2) |

|

|

Product Certifications |

- |

Patents(4) |

|

|

Trademarks(1) |

Main Markets |

|

|

Factory Size |

50,000-100,000 square meters |

|

Factory Country/Region |

No.2222, Century Avenue, High-tech Development Zone, Jinan City, Shandong Province, China |

|

No. of Production Lines |

7 |

|

Contract Manufacturing |

OEM Service Offered, Design Service Offered, Buyer Label Offered |

|

Annual Output Value |

US$10 Million – US$50 Million |

|

Product Name |

Production Line Capacity |

Actual Units Produced(Previous Year) |

|

CNC Angle Line |

400 Sets/Year |

400 Sets |

|

CNC Beam Drilling Sawing Machine |

270 Sets/Year |

270 Sets |

|

CNC Plate Drilling Machine |

350 Sets/Year |

350 Sets |

|

CNC Plate Punching Machine |

350 Sets/Year |

350 Sets |

|

Language Spoken |

English |

|

No. of Employees in Trade Department |

6-10 People |

|

Average Lead Time |

90 |

|

Export License Registration NO |

04640822 |

|

Total Annual Revenue |

confidential |

|

Total Export Revenue |

confidential |