PLD3020N Gantry Mobile CNC Plate Drilling Machine

| Plate size | Plate overlap thickness | Max. 100mm |

| Width × length | 3000mm×2000mm One piece | |

| 1500mm×2000mm Two pieces | ||

| 1000mm×1500mm Four Pieces | ||

| Principal axis | Quickly change the chuck | Morse 3 and 4 taper holes |

| Drill hole diameter | Φ12-Φ50mm | |

| Variable speed mode | Continuously variable speed of frequency converter | |

| RPM | 120-560r/min | |

| Stroke length | 180mm | |

| Machining feed | Stepless hydraulic speed regulation | |

| Plateclamping | Clamping thickness | 15-100mm |

| Number of clamping cylinders | 12 | |

| Clamping force | 7.5KN | |

| Coolant | Mode | Forced circulation |

| Electric machinery | Spindle motor | 5.5kW |

| Hydraulic pump motor | 2.2kW | |

| Chip conveyor motor | 0.4kW | |

| Cooling pump motor | 0.25kW | |

| X-axis servo motor | 1.5kW×2 | |

| Y-axis servo motor | 1.0kW | |

| Machine dimensions | long × wide × high | About 6183×3100×2850mm |

| weight | Machine | About 5500kg |

| Chip removal system | About 400kg | |

| Number of control axes | X. Y (point control) Z (spindle, hydraulic feed) | |

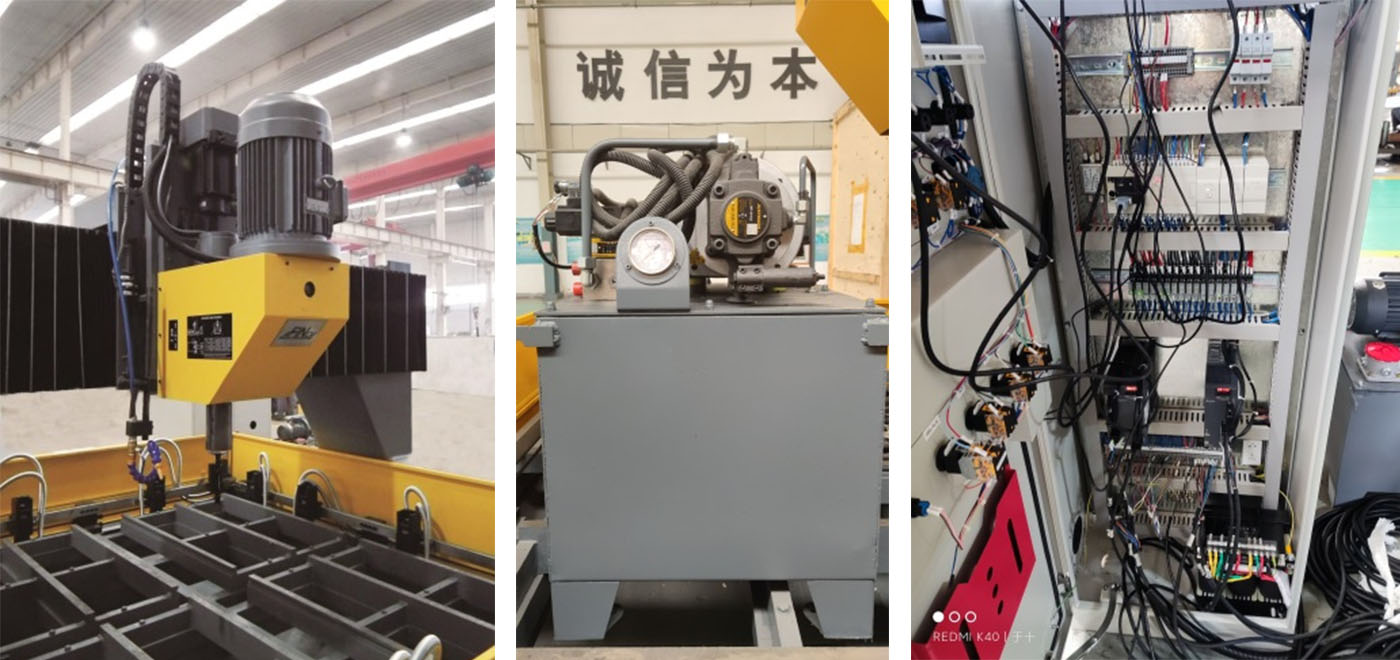

1. The machine tool mainly consists of bed, gantry, drilling power head, hydraulic system, control system, centralized lubrication system, chip removal system, cooling system, quick change chuck, etc.

2. Hydraulic automatic stroke power head is a patented technology of our company. Before use, it is unnecessary to set any parameters, and automatically convert the fast forward, work in and back, and realize it through the combination of mechanical and electrical hydraulic.

3. The plate is clamped by hydraulic clamp, and the operator is controlled by foot switch, which is convenient and labor-saving; Up to 3000 per piece × 2000mm, small plate can be clamped in the four corners of the workbench, which significantly shortens the production preparation period and improves the production efficiency.

4. There are two CNC axes in this machine tool: gantry movement (x axis); The movement of the drilling power head on the gantry beam (Y-axis). Each CNC axis is guided by precise linear rolling guide, driven by AC servo motor and ball screw. Flexible motion and precise positioning.

5. The machine tool adopts centralized lubrication system instead of manual operation, ensuring good lubrication of functional parts, improving machine performance and prolonging machine life.

6. The drill bit cooling of the machine adopts circulating water cooling, and the universal nozzle is installed on the drilling spindle box, and the coolant is always sprayed at the drilling place of the plate. The machine is equipped with a coolant filter circulation device. The bed is equipped with a chip remover, which can automatically discharge the chip.

7. The control program adopts the upper computer programming software which is developed by our company and matched with the programmable controller.

|

NO. |

Name |

Brand |

Country |

|

1 |

Linear guide rail |

CSK/HIWIN |

Taiwan (China) |

|

2 |

Hydraulic pump |

Just Mark |

Taiwan (China) |

|

3 |

Electromagnetic valve |

Atos/YUKEN |

Italy/Japan |

|

4 |

Servo motor |

Inovance |

China |

|

5 |

Servo driver |

Inovance |

China |

|

6 |

PLC |

Inovance |

China |

|

7 |

Computer |

Lenovo |

China |

Note: The above is our standard supplier. It's subject to be replaced by same quality components of other brand if the above supplier can't supply the components in case of any special matter.

Company Brief Profile  Factory Information

Factory Information  Annual Production Capacity

Annual Production Capacity  Trade Ability

Trade Ability