One of Hottest for Tube Drilling Machine - Horizontal Dual-spindle CNC Deep Hole Drilling Machine – FIN CNC

One of Hottest for Tube Drilling Machine - Horizontal Dual-spindle CNC Deep Hole Drilling Machine – FIN CNC Detail:

Product Parameters

| Item | Name | Parameter value | |||||

| DD25N-2 | DD40E-2 | DD40N-2 | DD50N-2 | ||||

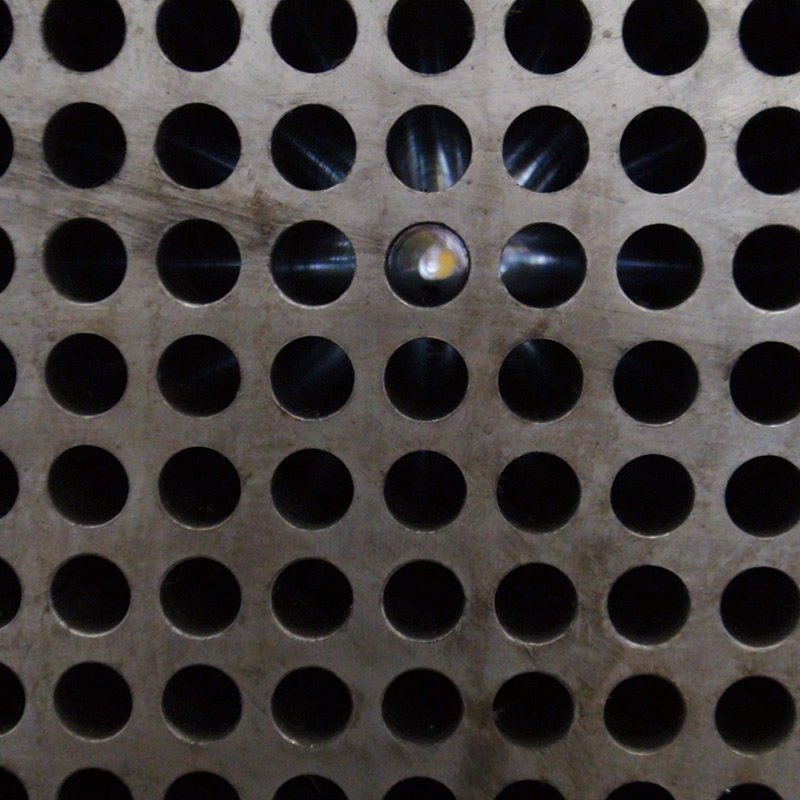

| Tube plate Dimension | Maximum drilling diameter | φ2500mm | Φ4000mm | φ5000mm | |||

| Borehole diameter | BTA drill | φ16~φ32mm | φ16~φ40mm | ||||

| Maximum drilling depth | 750mm | 800mm | 750mm | ||||

| Drilling Spindle | Quantity | 2 | |||||

| Spindle center distance (adjustable) | 170-220mm | ||||||

| Spindle front bearing diameter | φ65mm | ||||||

| Spindle speed | 200~2500r/min | ||||||

| Spindle variable frequency motor power | 2×15kW | 2×15Kw/20.5KW | 2×15kW | ||||

| Longitudinal slide movement (X-axis) |

Stroke | 3000mm | 4000mm | 5000mm | |||

| Maximum movement speed | 4m/min | ||||||

| Servo motor power | 4.5kW | 4.4KW | 4.5kW | ||||

| Vertical slide movement of column (Y-axis) |

Stroke | 2500mm | 2000mm | 2500mm | |||

| Maximum movement speed | 4m/min | ||||||

| Servo motor power | 4.5KW | 7.7KW | 4.5KW | ||||

| Movement of double spindle feed slide (Z axis) |

Stroke | 2500mm | 2000mm | 900mm | |||

| Feed rate | 0~4m/min | ||||||

| Servo motor power | 2KW | 2.6KW | 2.0KW | ||||

| Hydraulic system | Hydraulic pump pressure / flow | 2.5~5MPa,25L/min | |||||

| Motor power of hydraulic pump | 3kW | ||||||

| Cooling system | Cooling tank capacity | 3000L | |||||

| Industrial refrigerator power | 28.7kW | 2*22KW | 2*22KW | 2*14KW | |||

| Electrical system | CNC system | FAGOR8055 | Siemens828D | FAGOR8055 | FAGOR8055 | ||

| Number of CNC axes | 5 | 3 | 5 | ||||

| Total power of motor | About 112KW | About 125KW | About 112KW | ||||

| Machine dimensions | Length × width × height | About 13×8.2×6.2m | 13*8.2*6.2 | 14*7*6m | 15*8.2*6.2m | ||

| Machine weight | About 75tons | About 70tons | About 75tons | About 75tons | |||

| Accuracy | X-axis positioning accuracy | 0.04mm/ overall length | 0.06mm/ overall length | 0.10mm/ overall length | |||

| X-axis repeat positioning accuracy | 0.02mm | 0.03mm | 0.05mm | ||||

| Positioning accuracy of Y-axis | 0.03mm/ overall length | 0.06mm/overall length | 0.08mm/ overall length | ||||

| Y-axis repeat positioning accuracy | 0.02mm | 0.03mm | 0.04mm | ||||

| Tolerance of holes spacing | At Drilling tool Entrance Face | ±0.06mm | ±0.10mm | ±0.10mm | |||

| At Drilling tool Export Face | ±0.5mm/750mm | ±0.3-0.8mm/800mm | ±0.3-0.8mm/800mm | ±0.4nn750mm | |||

| Hole roundness | 0.02mm | ||||||

| Hole dimension accuracy | IT9~IT10 | ||||||

Details and advantages

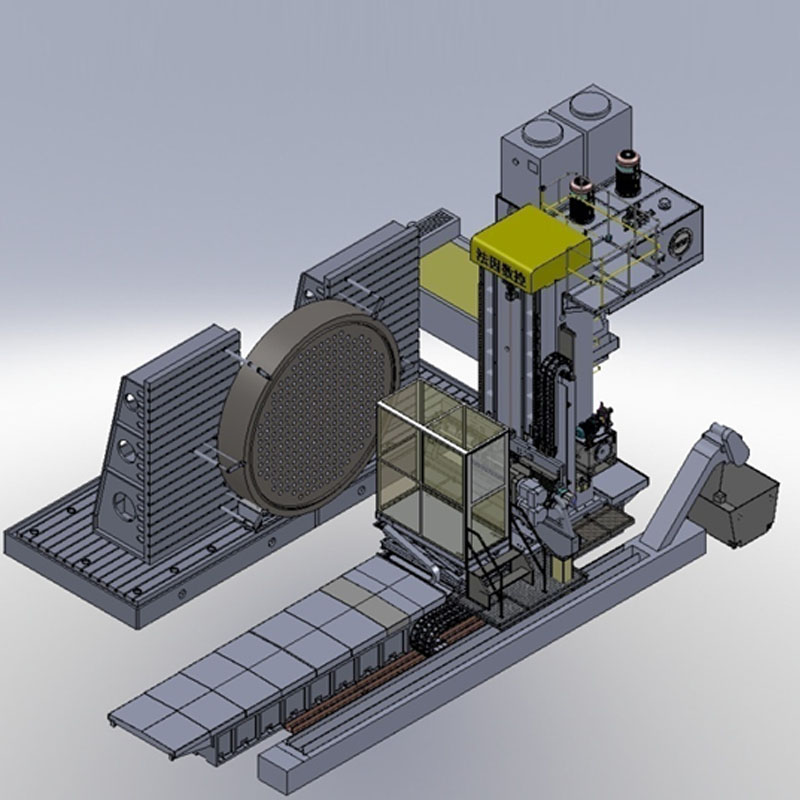

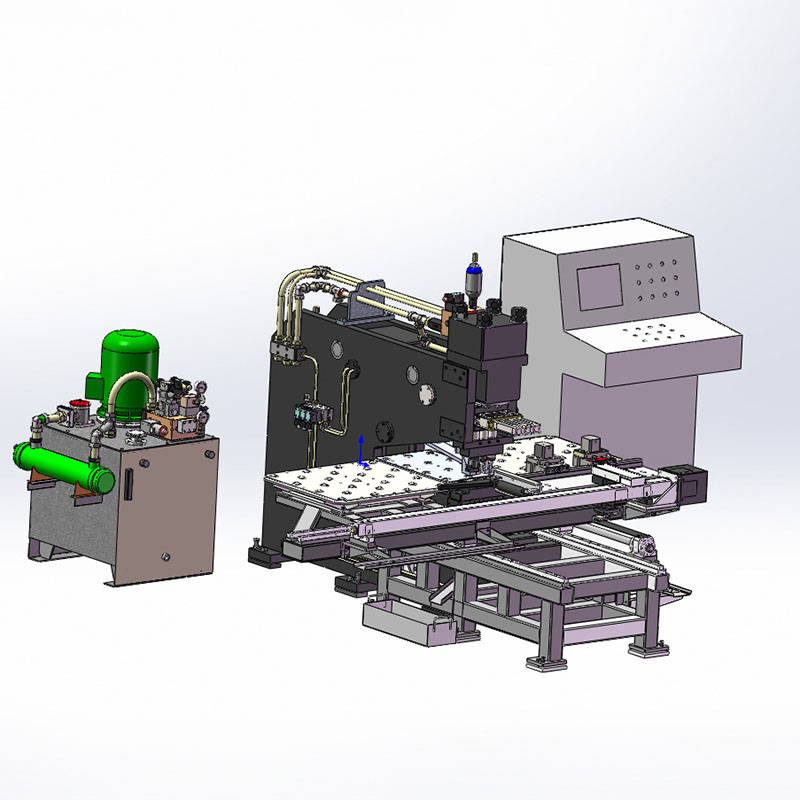

1. This machine belongs to horizontal deep hole drilling machine. The precision of the casting bed is stable, on which there is a longitudinal sliding table, which works to carry the column for longitudinal (X-direction) movement; the column is equipped with a vertical sliding table, which carries the spindle feed sliding table for vertical (Y-direction) movement; the spindle feed sliding table drives the spindle for feed (Z-direction) movement.

2. The X, Y and Z axis of the machine are all guided by linear roller guide pairs, which has extremely high bearing capacity and superior dynamic response performance, no gap and high motion accuracy.

3. The worktable of the machine is separated from the bed, so that the clamped material will not be affected by the vibration of the bed. The worktable is made from cast iron with stable precision.

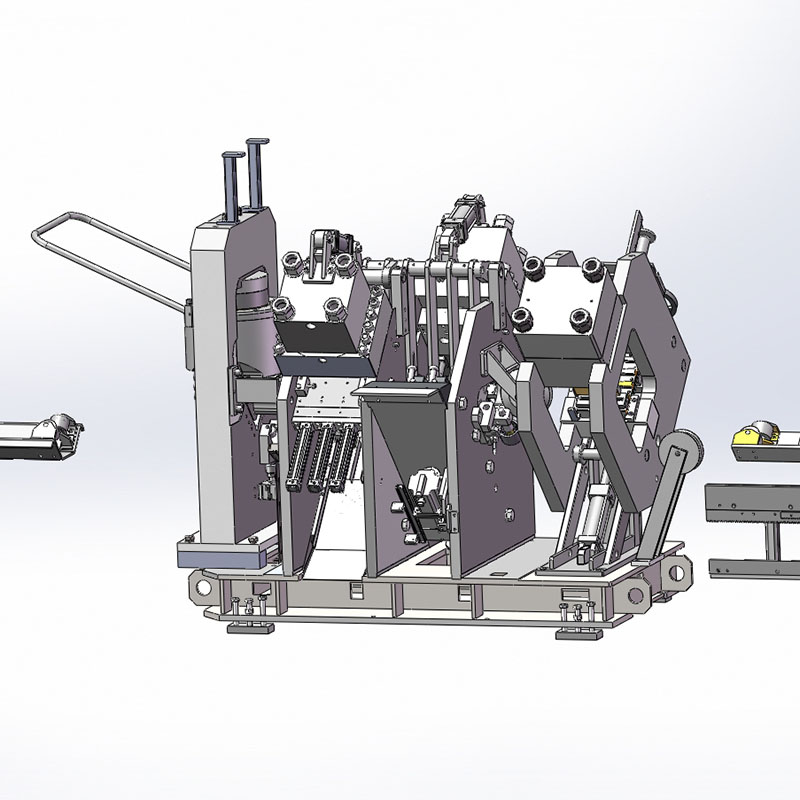

4. The machine has two spindles, which can work at the same time. The efficiency of the machine is nearly double that of the single spindle machine.

5. The machine is equipped with a flat chain type automatic chip remover. The iron chips generated by the drilling tool are sent to the chain type chip remover through the chip removal conveyor, and the chip removal works automatically.

6. The machine is equipped with automatic lubrication system, which can regularly lubricate the parts to be lubricated such as guide rail and screw, effectively ensuring the stable operation of the machine and improving the service life of each part.

7. Simens828D/ FAGOR8055 numerical control system is adopted in the machine numerical control system, which is equipped with electronic hand wheel, so it is convenient for operation and maintenance.

Key outsourced components list

|

NO |

Name |

Brand |

Country |

|

1 |

Linear guide rail |

HIWIN/PMI |

Taiwan(China) |

|

2 |

CNC system |

SIEMENS |

Germany |

|

3 |

Planetary gear reducer |

APEX |

Taiwan(China) |

|

4 |

Internal cooling joint |

DEUBLIN |

USA |

|

5 |

Oil pump |

JUSTMARK |

Taiwan(China) |

|

6 |

Hydraulic valve |

ATOS |

Italy |

|

7 |

Feed servo motor |

Panasonic |

Japan |

|

8 |

Switch, button, indicator light |

Schneider/ABB |

France / Germany |

|

9 |

Automatic lubrication system |

BIJUR/HERG |

USA / Japan |

Note: The above is our standard supplier. It’s subject to be replaced by same quality components of other brand if the above supplier can’t supply the components in case of any special matter.

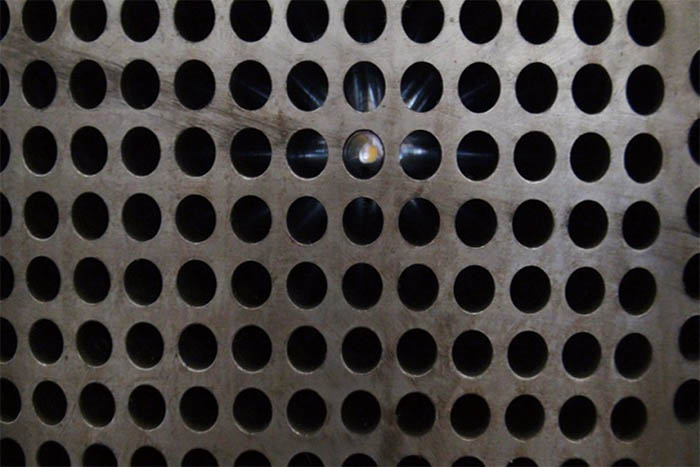

Product detail pictures:

Related Product Guide:

We always believe that one's character decides products' quality, the details decides products' quality ,with the REALISTIC,EFFICIENT AND INNOVATIVE team spirit for One of Hottest for Tube Drilling Machine - Horizontal Dual-spindle CNC Deep Hole Drilling Machine – FIN CNC , The product will supply to all over the world, such as: Slovenia, Luxembourg, Oman, We have our own registered brand and our company is developing rapidly owing to high quality products, competitive price and excellent service. We sincerely hope to establish business relations with more friends from home and abroad in the near future. We look forward to your correspondence.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!