OEM/ODM Manufacturer High Speed Milling Machine - Hydraulic Angle Notching Machine – FIN CNC

OEM/ODM Manufacturer High Speed Milling Machine - Hydraulic Angle Notching Machine – FIN CNC Detail:

Product Parameters

| No. | Item | Parameter | |

| ACH140 | ACH200 | ||

| 1 | Nominal force | 560 KN | 1000KN |

| 2 | Rated pressure of hydraulic system | 22Mpa | |

| 3 | Number of no-load running | 20 times/min | |

| 4 | Single blade cutting |

140*140*16mm (material Q235-A, Max. Tensile Strengthσb≈410MPa) |

200*200*20mm (material Q235-A, Max. Tensile Strengthσb≈410MPa) |

| 5 | 140*140*14mm (material 16Mn, Max. Tensile Strengthσb≈600MPa) |

||

| 6 | 140*140*12mm (material Q420, Max. Tensile Strengthσb≈680MPa) |

200*200*16mm (material Q420, Max. Tensile Strengthσb≈680MPa) |

|

| 7 | Shearing angle | 0°~45° | |

| 8 | Maximum cutting length | 200 mm | 300mm |

| 9 | Square angle cutting |

140*140*12mm(Q235-A, Maximum tensile strengthσb≈410MPa) | 200*200*16mm(Q235-A, Maximum tensile strengthσb≈410MPa) |

| 10 | 140*140*10mm(16Mn, Maximum tensile strengthσb≈600MPa) | 200*200*12mm(16Mn, Maximum tensile strengthσb≈600MPa) | |

| 11 | Ambient temperature | 0℃~40℃ | |

| 12 | Motor power of hydraulic pump | 15KW | 18.5KW |

| 13 | Machine overall size (L*W*H) |

2000*1100*1850mm | 2635*1200*2090MM |

| 14 | Machine weight | About 3000kg | About 6500kg |

Details and advantages

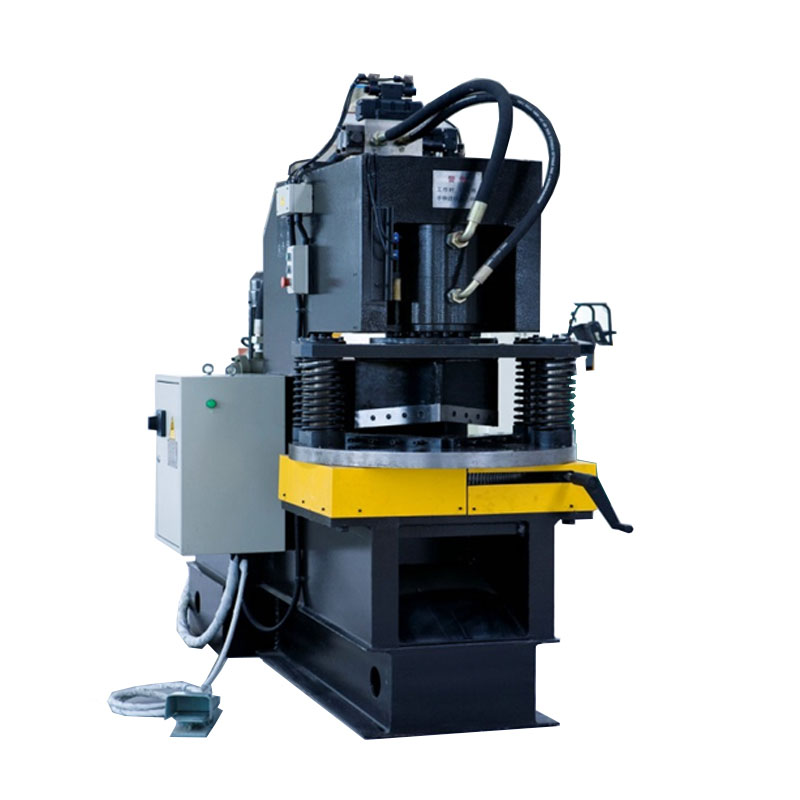

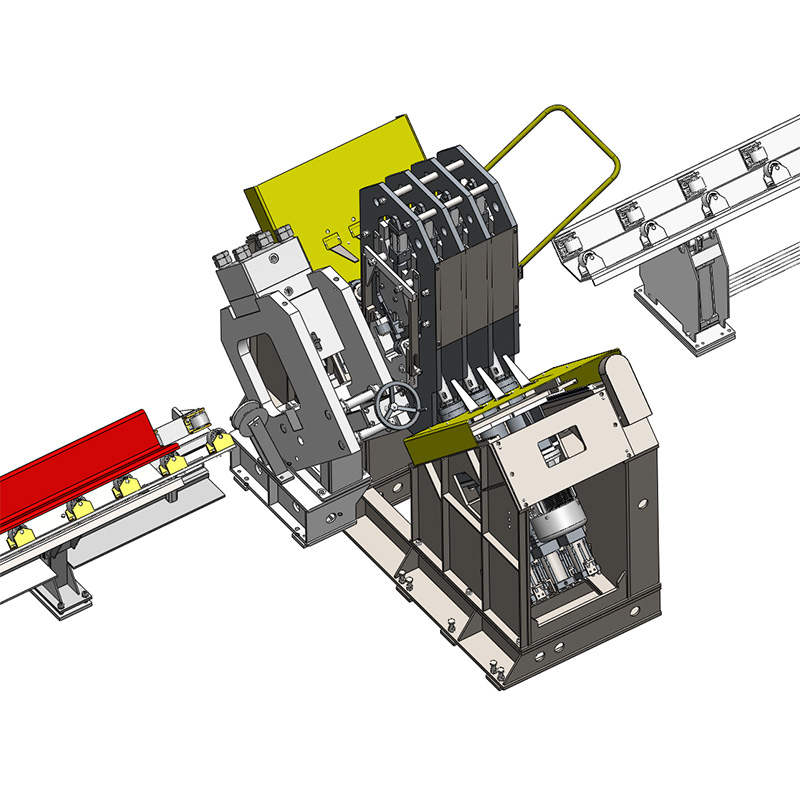

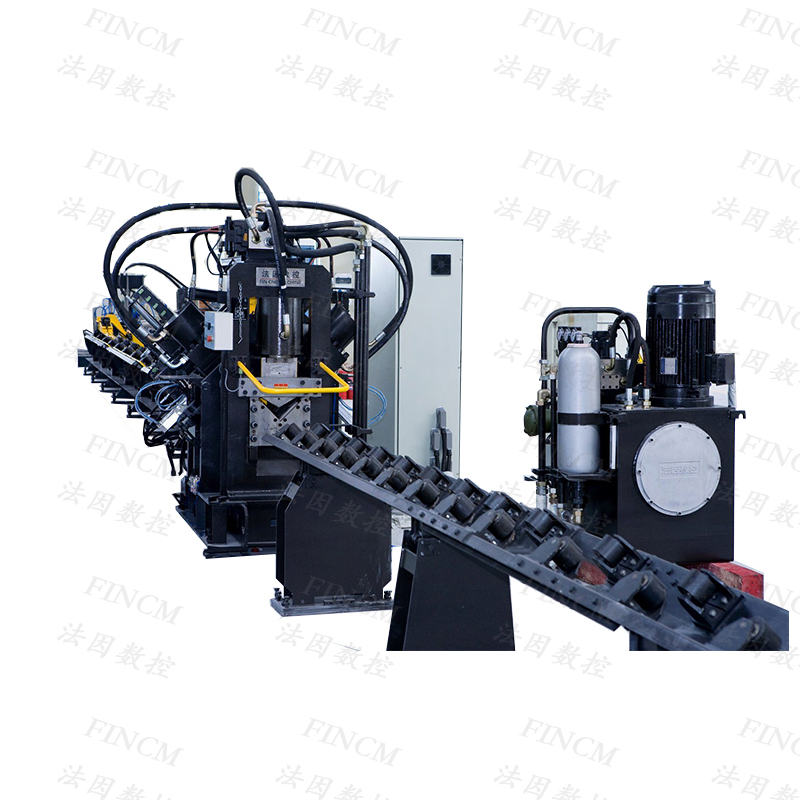

This product is composed of a main machine, cutting mould, and a hydraulic station, and is equipped with an electrical system to fulfill angle cutting.

1. Main machine

The main machine is welded by steel plates in a C shape. The upper part is the oil cylinder, and the lower part is the working table, which provides support for the mould and meets the strength and rigidity requirements of the machine.

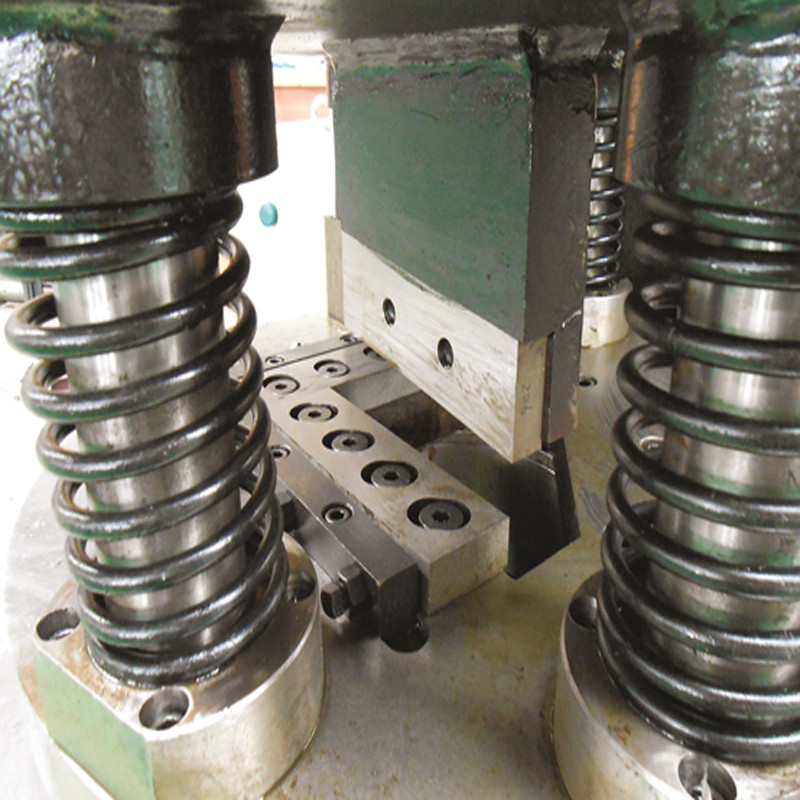

2. Mould

The mould part is guided by sliding rails, this structure bears large partial loads and has high guiding accuracy.

3. Hydraulic station

The hydraulic system is composed of oil tank, motor, high and low pressure pump, control valve, oil filter shearing cylinder, etc. It is the power source of shearing cylinder. The electromagnetic reversing valve, overflow valve, unloading valve, etc. are imported parts with reliable performance and long service life.

Product detail pictures:

Related Product Guide:

We not only will try our greatest to offer you excellent services to just about every client, but also are ready to receive any suggestion offered by our buyers for OEM/ODM Manufacturer High Speed Milling Machine - Hydraulic Angle Notching Machine – FIN CNC , The product will supply to all over the world, such as: Argentina, Estonia, Islamabad, we have 8 years experience of production and 5 years experience in trading with the customers all over the world. our clients mainly distributed in the North America, Africa and Eastern Europe. we can supply high quality products with the very competitive price.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.