OEM/ODM China Machine Shearing - PPHD123 CNC Hydraulic Press Plate Punching and Drilling Machine – FIN CNC

OEM/ODM China Machine Shearing - PPHD123 CNC Hydraulic Press Plate Punching and Drilling Machine – FIN CNC Detail:

Product Parameter

|

NO. |

Item |

Parameter |

||

|

1 |

Punching capacity |

1500KN |

||

|

2 |

Maximum plate size |

1500×775mm |

||

|

3 |

Plate thickness range |

5~25 |

||

|

4 |

Modulus |

Number of punching and marking dies |

3 |

|

|

5 |

Processing capacity |

Maximum punch diameter |

φ30mm |

|

|

For Q345 steel, σ B ≤ 610mpa, φ 30*25mm (diameter* thickness) For Q420 steel, σ B ≤ 680mpa, φ 26* 25mm (diameter* thickness) |

||||

|

6 |

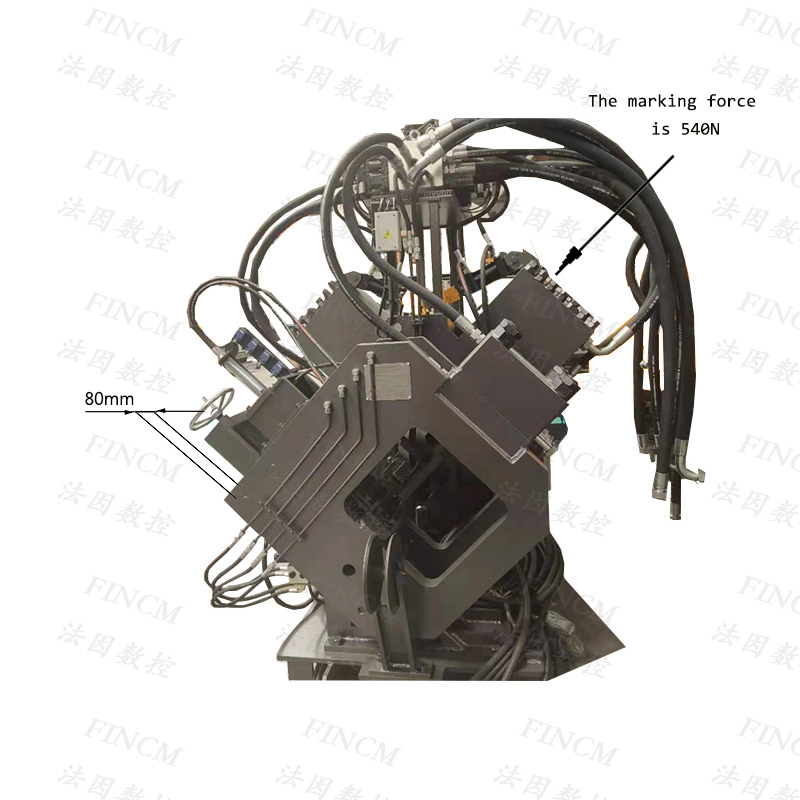

Marking ability |

Marking ability |

800KN |

|

|

Characters size |

14×10mm |

|||

|

7 |

Number of prefix characters in a group |

10 |

||

|

8 |

Minimum hole margin |

25mm |

||

|

9 |

Number of clamps |

2 |

||

|

10 |

System pressure |

High pressure |

24Mpa |

|

|

Low pressure |

6Mpa |

|||

|

11 |

Air pressure |

0.5Mpa |

||

|

12 |

Motor power of hydraulic pump |

22KW |

||

|

13 |

Number of CNC axes |

2 |

||

|

14 |

X. Y-axis speed |

18m/min |

||

|

15 |

X-axis servo motor power |

2KW |

||

|

16 |

Y-axis servo motor power |

2KW |

||

|

17 |

Cooling mode |

Water-cooling |

||

|

18 |

Total power |

26KW |

||

|

19 |

Machine dimensions (L*W*H) |

3650*2700*2350mm |

||

|

20 |

Machine weight |

9500Kg |

||

Details and advantages

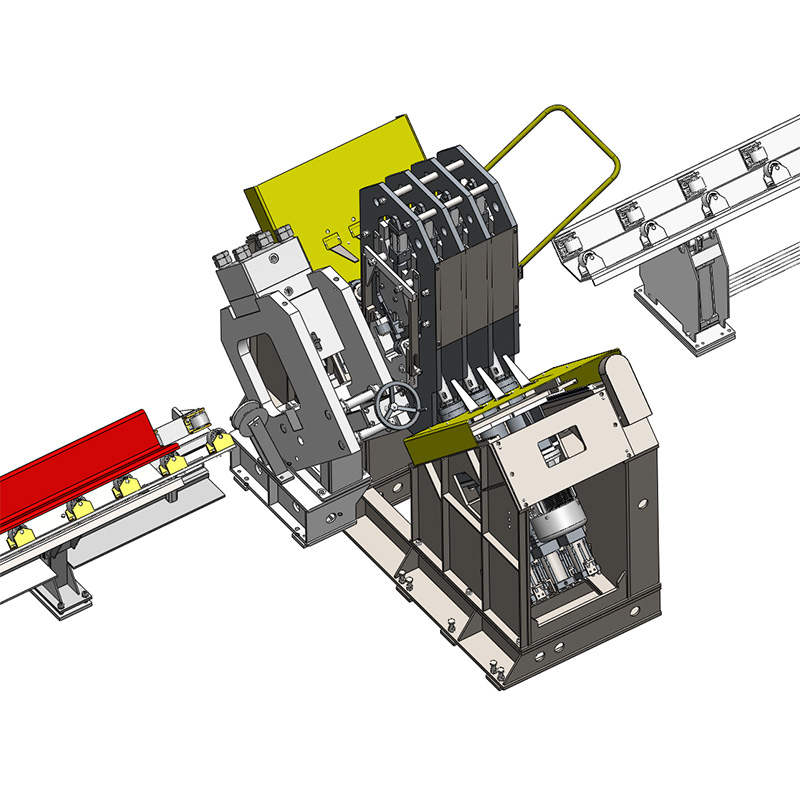

1. The PPHD123 CNC hydraulic punching machine has a punching force up to 1200KN. It has three die positions and can be installed with three sets of punching dies, or only two sets of punching dies and a character box. The die is easy to replace and the print is clear.

2. Equipped with a CNC drilling power head, which adopts a special spindle frequency conversion motor of strong overload type, and the motor drives the drilling spindle to rotate through a synchronous belt. The servo motor drives the feeding of the CNC drilling power head, and the fast forward, work advance and fast reverse of the drill are controlled by the CNC system and completed automatically.

3. The machine has two CNC axes: the X axis is the left and right movement of the clamp, the Y axis is the front and rear movement of the clamp, and the high-rigid CNC worktable ensures the reliability and precision of feeding.

4. Both X and Y axes use precision linear guides, which have large load, high precision, long service life of the guides, and can maintain the high precision of the machine for a long time.

5. Use the combination of centralized lubrication and distributed lubrication to lubricate the machine, so that the machine is always in good working condition.

6. The plate is clamped by two powerful hydraulic clamps and moves quickly for positioning.

7. The control system adopts Siemens latest CNC system SINUMERIK 808D or Yokogawa PLC, with high reliability, convenient diagnosis and easy operation.

8. The plate is processed and positioned quickly, easy to operate, small footprint, and high production efficiency.

Key outsourced components

|

NO. |

Name |

Brand |

Country |

|

1 |

Linear guide rail |

HIWIN/PMI |

Taiwan(China) |

|

2 |

Oil pump |

Albert |

USA |

|

3 |

Electromagnetic relief valve |

Atos |

Italy |

|

4 |

Electromagnetic unloading valve |

Atos |

Italy |

|

5 |

Solenoid valve |

Atos |

Italy |

|

6 |

One way throttle valve |

Atos |

Italy |

|

7 |

P-port throttle valve |

JUSTMARK |

Taiwan(China) |

|

8 |

P port check valve |

JUSTMARK |

Taiwan(China) |

|

9 |

Hydraulic control check valve |

JUSTMARK |

Taiwan(China) |

|

10 |

Drag chain |

JFLO |

China |

|

11 |

Air valve |

CKD/SMC |

Japan |

|

12 |

Confluence |

CKD/SMC |

Japan |

|

13 |

Cylinder |

CKD/SMC |

Japan |

|

14 |

FRL |

CKD/SMC |

Japan |

|

15 |

AC servo motor |

Panasonics |

Japan |

|

16 |

PLC |

Mitsubishi |

Japan |

Note: The above is our fixed supplier. It’s subject to be replaced by same quality components of other brand if the above supplier can’t supply the components in case of any special matter.

Product detail pictures:

Related Product Guide:

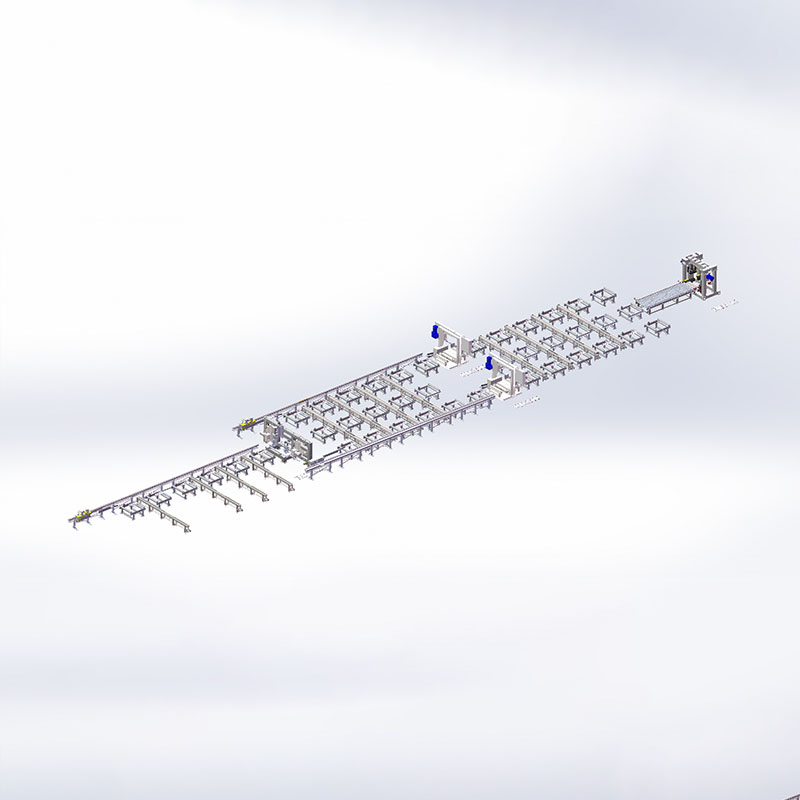

We have been experienced manufacturer. Wining the majority of the crucial certifications of its market for OEM/ODM China Machine Shearing - PPHD123 CNC Hydraulic Press Plate Punching and Drilling Machine – FIN CNC , The product will supply to all over the world, such as: Cannes, Latvia, Uruguay, We have top engineers in these industries and an efficient team in the research. What is more, we have our own archives mouths and markets in China at low cost. Therefore, we can meet different inquiries from different clients. Please find our website to check more information from our products.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!