OEM/ODM China China CNC Drilling Machine, Steel Plate Tapping and Drilling Machinery

We’ve been convinced that with joint efforts, the enterprise between us will bring us mutual benefits. We are able to assure you product or service quality and aggressive cost for OEM/ODM China China CNC Drilling Machine, Steel Plate Tapping and Drilling Machinery, Our professional technical team will be wholeheartedly at your service. We sincerely welcome you to visit our website and company and send us your inquiry.

We’ve been convinced that with joint efforts, the enterprise between us will bring us mutual benefits. We are able to assure you product or service quality and aggressive cost for China CNC Drilling Machine, CNC Tapping and Drilling Machine, Steel plate, The working experience in the field has helped us forged a strong relations with customers and partners both in domestic and international market. For years, our products have been exported to more than 15 countries in the world and have been widely used by customers.

Product Parameters

| Item | Name | Value |

| Size of plate | Thickness of plate | Max 100mm |

| Width*Length | 2000mm×1600mm (One piece) | |

| 1600mm*1000mm (Two pieces) | ||

| 1000mm×800mm (Four pieces) | ||

| Drilling spindle | Quick-change drill chuck | Morse 3#,4# |

| Diameter of drilling head | Φ12mm-Φ50mm | |

| The mode of speed adjustment | Transducer stepless speed adjustment | |

| RPM | 120-560r/min | |

| Stroke | 180mm | |

| Hydraulic clamping | Thickness of clamping | 15-100mm |

| Quantity of clamping cylinder | 12 pieces | |

| Clamping force | 7.5kN | |

| Cooling fluid | Mode | Forcing cycle |

| Motor | Spindle | 5.5kW |

| Hydraulic pump | 2.2kW | |

| Chip removal motor | 0.75kW | |

| Cooling pump | 0.25kW | |

| Servo system of X axis | 1.5kW | |

| Servo system of Y axis | 1.0kW | |

| Overall dimensions | L*W*H | About 5183*2705*2856mm |

| Weight(KG) | Main machine | About 4500kg |

| Scrap Removal Device | About 800kg | |

| Travel | X Axis | 2000mm |

| Y Axis | 1600mm |

Details and advantages

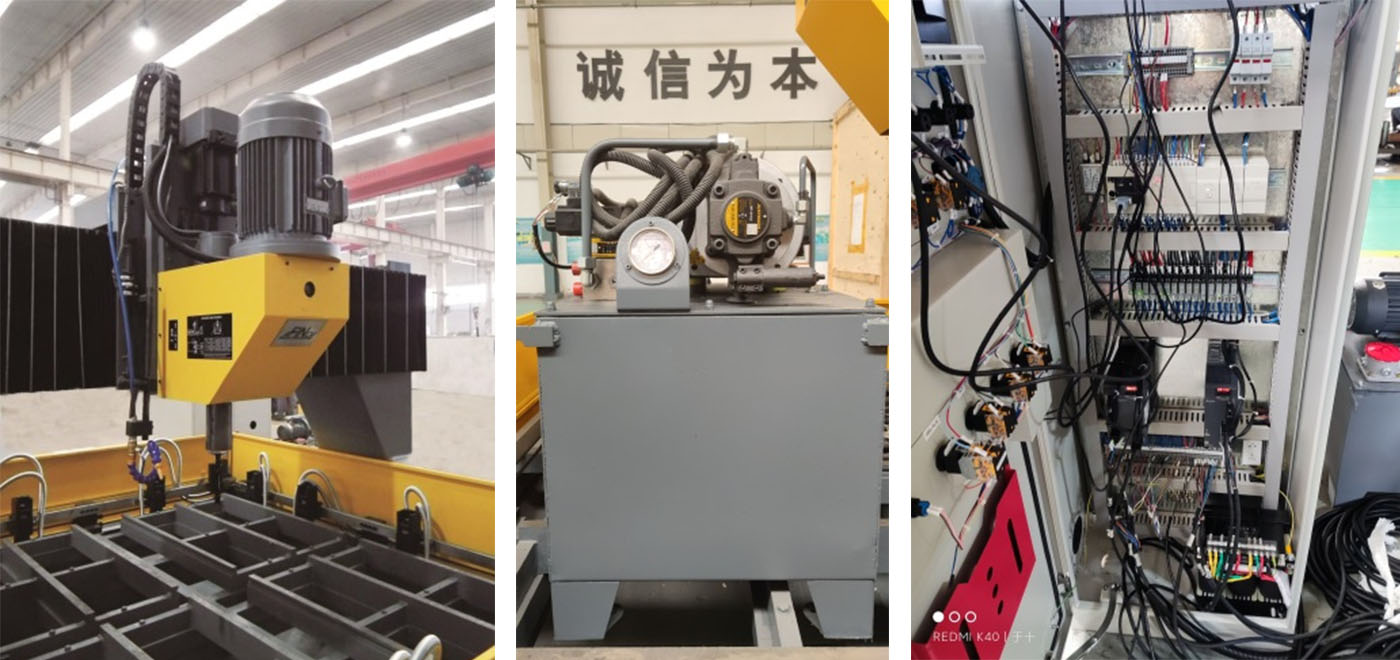

1. The machine is mainly composed of bed (worktable),gantry, drilling head, longitudinal slide platform, hydraulic system, Electric control system, centralized lubrication system, cooling chip removal system, quick change chuck etc.

2. The gantry moves while the bed is fixed. Plates are clamped by the hydraulic clamps which can easily controlled by foot-switch, small plate can clamped four groups together on the corners of worktable so as to reduce the preparation period of production and improve the efficiency significantly.

3. The machine including two CNC axes, each of all is guided by high precision linear rolling guide, drive by AC servo motor and ball-screw.

4. The machine purpose adopts hydraulic automatic control stroke drilling power head, which is our company’s patented technology, no need to set any parameters before use.

5. The machine purpose adopts hydraulic automatic control stroke drilling power head, which is our company’s patented technology. There is no need to set any parameters before use. Through the combined action of electro-hydraulic, it can automatically carry out the conversion of fast forward-work forward-fast backward, and the operation is simple and reliable.

6. This machine purpose adopts a centralized lubrication system instead of manual operation to ensure that the functional parts are well lubricated, improve the performance of the machine tool, and extend its service life.

7. The two methods of internal cooling and external cooling ensure the effect of cooling the drill head. The chips can be dumped into the dumpcart automatically.

The control system adopts the upper computer programming software which is independently developed by our company and matched with the programmable controller, which has a high degree of automation.

Key outsourced components list

|

NO. |

Name |

Brand |

Country |

|

1 |

Linear guide rail |

CSK/HIWIN |

Taiwan (China) |

|

2 |

Hydraulic pump |

Just Mark |

Taiwan (China) |

|

3 |

Electromagnetic valve |

Atos/YUKEN |

Italy/Japan |

|

4 |

Servo motor |

Inovance |

China |

|

5 |

Servo driver |

Inovance |

China |

|

6 |

PLC |

Inovance |

China |

|

7 |

Computer |

Lenovo |

China |

Note: The above is our standard supplier. It’s subject to be replaced by same quality components of other brand if the above supplier can’t supply the components in case of any special matter.

We’ve been convinced that with joint efforts, the enterprise between us will bring us mutual benefits. We are able to assure you product or service quality and aggressive cost for OEM/ODM China China CNC Drilling Machine, Steel Plate Tapping and Drilling Machinery, Our professional technical team will be wholeheartedly at your service. We sincerely welcome you to visit our website and company and send us your inquiry.

OEM/ODM China China CNC Drilling Machine, CNC Plate Tapping And Drilling Machine, The working experience in the field has helped us forged a strong relations with customers and partners both in domestic and international market. For years, our products have been exported to more than 15 countries in the world and have been widely used by customers.

Company Brief Profile  Factory Information

Factory Information  Annual Production Capacity

Annual Production Capacity  Trade Ability

Trade Ability