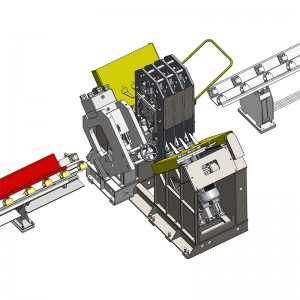

OEM China China CNC H Beam Drilling Machine for Steel Frame Construction Structure

Our advancement depends on the superior gear ,superb talents and consistently strengthened technology forces for OEM China China CNC H Beam Drilling Machine for Steel Frame Construction Structure, We’ve been hunting ahead to even better cooperation with abroad prospects based on mutual advantages. Make sure you really feel free to speak to us for additional depth!

Our advancement depends on the superior gear ,superb talents and consistently strengthened technology forces for 3D Drilling Machine, China CNC Beam Drilling Machine, Relying on superior quality and excellent post-sales, our items sell well in America, Europe, the Middle East and South Africa. We have been also the appointed OEM factory for several worlds’ famous products brands. Welcome to contact us for further negotiation and cooperation.

Product Parameters

| Parameter value | ||||||||

| Parameter name | Unit | SWZ400-9 | SWZ1000C | SWZ1250C | ||||

| Scope of Beam Dimension | Section steel | mm | 150*75-400*300 | 150*75-1000*50 | 150*751250*600 | |||

| Thickness | mm | ≤80 | ||||||

| Length | m | 12m (Configure according to customer demand) | 15m (Configure according to customer demand) | |||||

| Short material limit | mm | Automatic processing≥1500 | Automatic processing≥3000 | |||||

| Manual processing: ≤ 500 |

Manual processing: 690-3000 |

|||||||

| Spindle | Quantity | 3 | ||||||

| Drill hole Range |

Fixed side, mobile side | mm | ∅ 12~ ∅ 30 | ∅ 12~ ∅ 26.5 | ||||

| Intermediate unit | mm | ∅12~ ∅40 | ∅12~ ∅33.5 | |||||

| Spindle RPM | r/min | 180~560 | 180-560 | |||||

| Change the card head quickly | / | Morse taper hole 4#(Can change) | Morse taper hole 4#(Can change) | |||||

| Axial stroke | Fixed side, mobile side | mm | 140 | |||||

| Intermediate unit | mm | 325 | 240 | |||||

| Axial feed rate | mm/min | 20-300 | ||||||

| Moving distance | Each spindle is in the direction of beam length | mm | 520 | |||||

| Both sides of the spindle in the up and down direction | mm | 35-470 | 35-570 | |||||

| The intermediate unit is in the direction of beam width | mm | 45-910 | 45-1160 | |||||

| Machining accuracy | Error of adjacent hole spacing in hole group | mm | ≤±0.5 | |||||

| Feeding error within 10 m length | mm | ≤±1 | ||||||

| Electric motor power | Three phase asynchronous motor for spindle rotation | kW | 4*3 | |||||

| Intermediate unit X-axis servo motor | kW | 1.0 | 0.85*2 | |||||

| Z-axis servo motor of intermediate unit | kW | 1.5 | 1.3 | |||||

| Fixed side and mobile side X-axis servo motor | kW | 1.5 | 1.0 | 0.85 | ||||

| Fixed side and mobile side Y-axis servo motor | kW | 1.5 | 1.5 | 1.3 | ||||

| Moving carriage three phase asynchronous motor | kW | 4 | 0.55 | 0.55 | ||||

| Over dimension | mm | 4.4*1.4*2.7 | 4.4*2.4*3.5 | 4.8*2.4*3.3 | ||||

| Main Machine Weight | kg | 4300 | 6000 | 7000 | ||||

Details and advantages

1. The machine is a frame structure welded by high-quality steel. The steel pipe is strengthened in the place by large stress. After welding, the heat aging treatment is carried out to improve the stability of the bed.

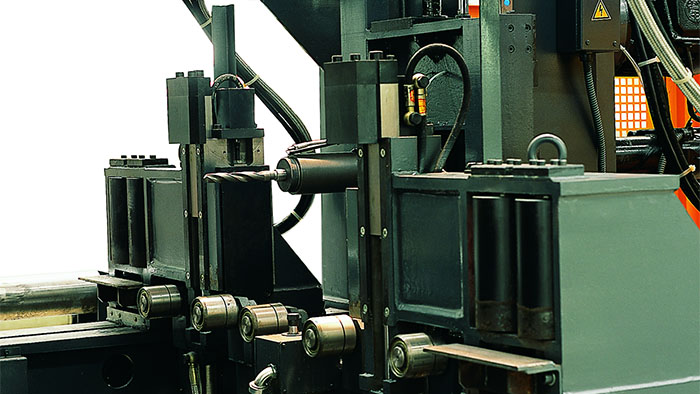

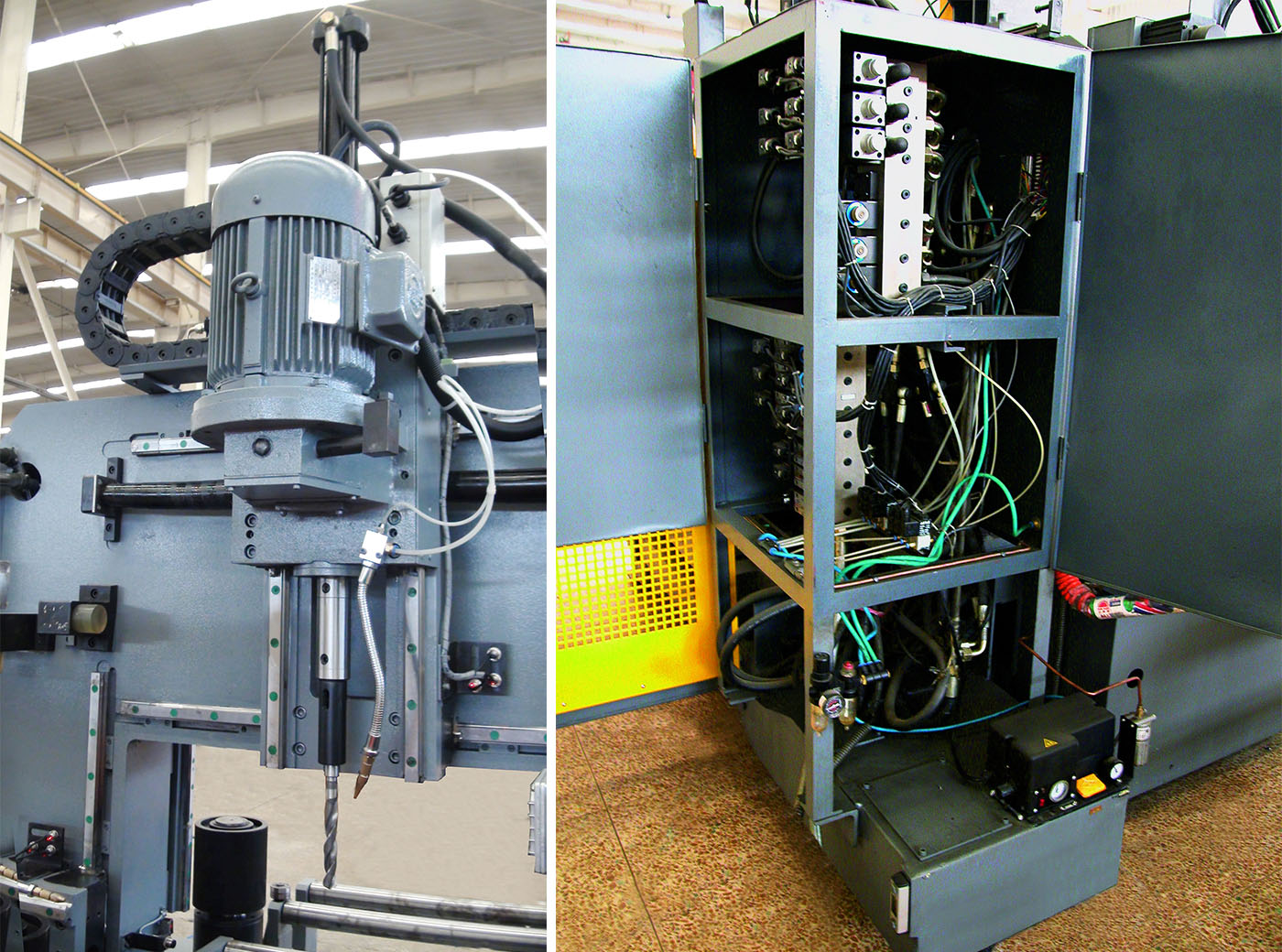

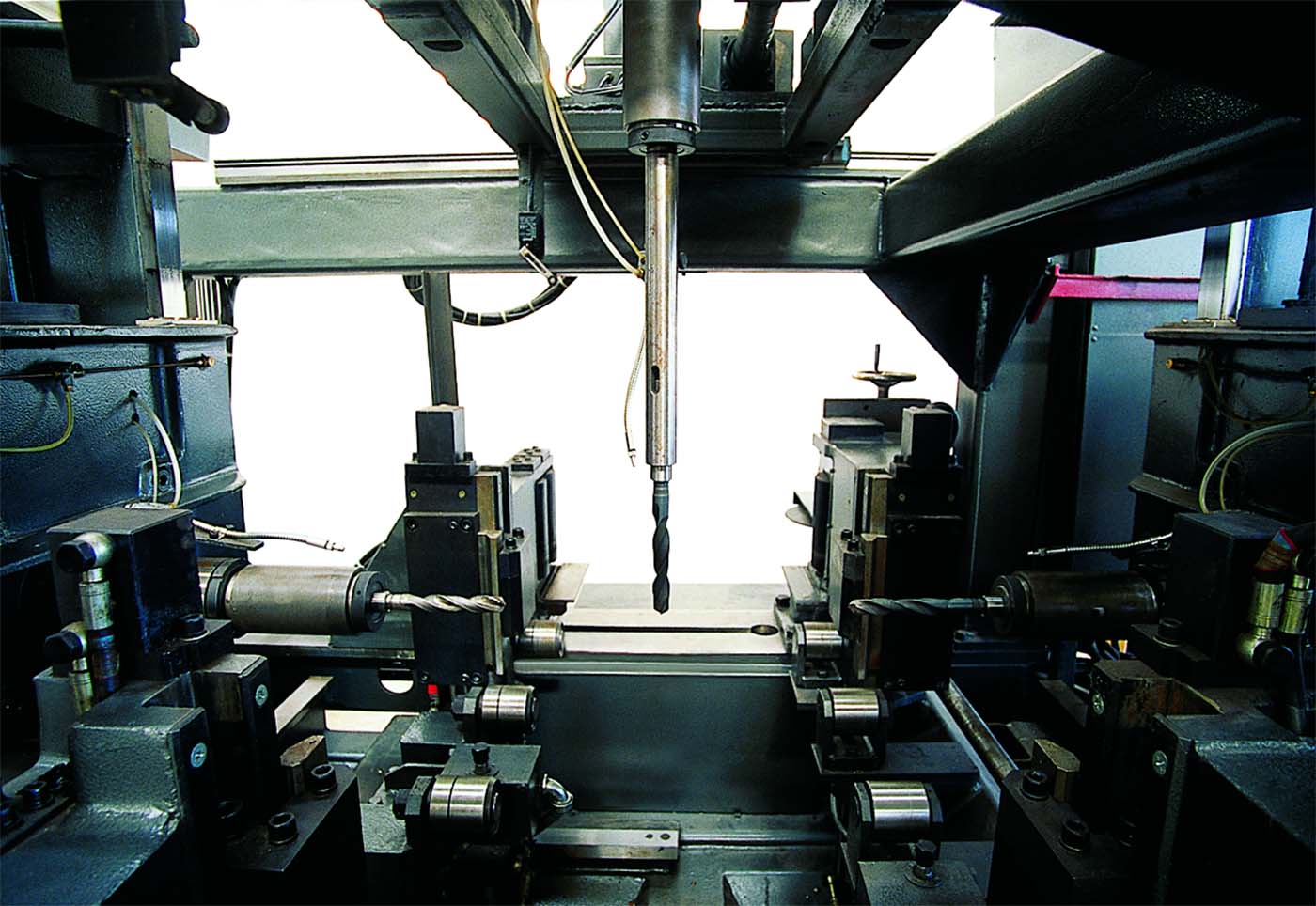

2. There are 3 CNC slides, 6 CNC axes on each slide, and 2 CNC axes on each slide. Each CNC axis is guided by precision linear rolling guide and driven by AC servo motor and ball screw. The holes on the same section of the beam can be processed at the same time, which greatly improves the positioning accuracy and efficiency of the holes in the hole group.

3. Three automatic control stroke drilling power heads are respectively installed on three CNC slide blocks for horizontal and vertical drilling. The three drilling power heads can work independently or simultaneously.

4. The spindle speed of each drilling power head is controlled by frequency converter and stepless adjusted; the feed speed is stepless adjusted by speed regulating valve, which can be adjusted rapidly in a large range according to the material of beam and diameter of drilling hole.

5. The beam is fixed by hydraulic clamping mechanism.

6. The machine is equipped with the detection device of the width of the beam and the height of the web, which can automatically compensate the machining error caused by the irregular outline of the material, and improve the machining accuracy.

7. The machine tool is equipped with an advanced cooling system, which has the advantages of less coolant consumption, cost saving and less bit wear.

Key outsourced components list

|

NO. |

Name |

Brand |

Country |

|

1 |

Linear guide rail |

Hiwin/CSK |

Taiwan (China) |

|

2 |

Electromagnetic hydraulic valve |

Atos/Yuken |

Italy/Japan |

|

3 |

Hydraulic pump |

Justmark |

Taiwan (China) |

|

4 |

Servo motor |

Panasonics |

Japan |

|

5 |

Servo driver |

Panasonics |

Japan |

|

6 |

PLC |

Mitsubishi |

Japan |

|

7 |

Spray cooling pump |

Bijur |

USA |

|

8 |

Flexible extension nozzle |

Bijur |

USA |

|

9 |

Pneumatic solenoid valve |

Airtac |

Taiwan (China) |

|

10 |

Centralized lubrication |

Herg/Bijur |

Japan/USA |

|

11 |

Computer |

Lenovo |

China |

Note: The above is our standard supplier. It’s subject to be replaced by same quality components of other brand if the above supplier can’t supply the components in case of any special matter.

Our advancement depends on the superior gear ,superb talents and consistently strengthened technology forces for OEM China China CNC H Beam Drilling Machine for Steel Frame Construction Structure, We’ve been hunting ahead to even better cooperation with abroad prospects based on mutual advantages. Make sure you really feel free to speak to us for additional depth!

OEM China China CNC Beam Drilling Machine, 3D Drilling Machine, Relying on superior quality and excellent post-sales, our items sell well in America, Europe, the Middle East and South Africa. We have been also the appointed OEM factory for several worlds’ famous products brands. Welcome to contact us for further negotiation and cooperation.

Company Brief Profile  Factory Information

Factory Information  Annual Production Capacity

Annual Production Capacity  Trade Ability

Trade Ability