OEM China Angle Drilling Machine - PHM Series Gantry Movable CNC Plate Drilling Machine – FIN CNC

OEM China Angle Drilling Machine - PHM Series Gantry Movable CNC Plate Drilling Machine – FIN CNC Detail:

Product Parameters

| Item | Name | Parameter | ||||

| PHM3030B | PHM4040C-2 | PHM5050C-2 | PHM6060A-2 | |||

| Maximum Plate Size | L x W | 3000*3000 mm | 4000*4000mm | 5000*5000nn | 6000*6000mm | |

| Maximum Thickness | 250mm | |||||

| Work Table | T Slot Width | 28 mm(standard) | ||||

| Loading Weight | 3ton/㎡ | |||||

| Drilling Spindle | Maximum Drilling hole Diameter | Φ80 mm | ||||

| Drilling spindle’s Rod Length vs. Hole diameter | ≤10 | |||||

| Maximum Tapping screw | M30 | |||||

| Spindle RPM | 30~3000 r/min | |||||

| Spindle Tape | BT50 | |||||

| Spindle motor power | 2*37kW | |||||

| Maximum Torque n≤750r/min | 470Nm | |||||

| Distance from Spindle bottom surface to the worktable | 280~780 mm (adjustable as per material thickness) |

|||||

| Positioning accuracy | X axis, Y axis | 0.052mm/full stroke | 0.064mm/full stroke |

0.08mm/full stroke | 0.1mm/full travel | |

| Repeatable positioning accuracy | X axis, Y axis | 0.033mm/full travel | 0.04mm/full travel |

0.05mm/full travel | 0.06mm/full travel | |

| Hydraulic system | Hydraulic pump pressure/Flow rate | 15MPa /22L/min | ||||

| Hydraulic pump motor power | 5.5 kW | |||||

| Pneumatic system | Compressed air pressure | 0.5 MPa | ||||

| Electronic system | CNC control system | Siemens 828D | ||||

| CNC Axis Number | 4 | 6 | ||||

| Total power | About 65KW | About 110kW | ||||

| Overall Dimension | L×W×H | About 7.8×6.7×4.1m | About 8.8×7.7×4.1m |

About 9.8×8.7×4.1m | About 9.8×8.7×4.1m | |

| Main machine weight | About 30/35Tons | About 42tons | About 50tons | About 60tons | ||

Details and advantages

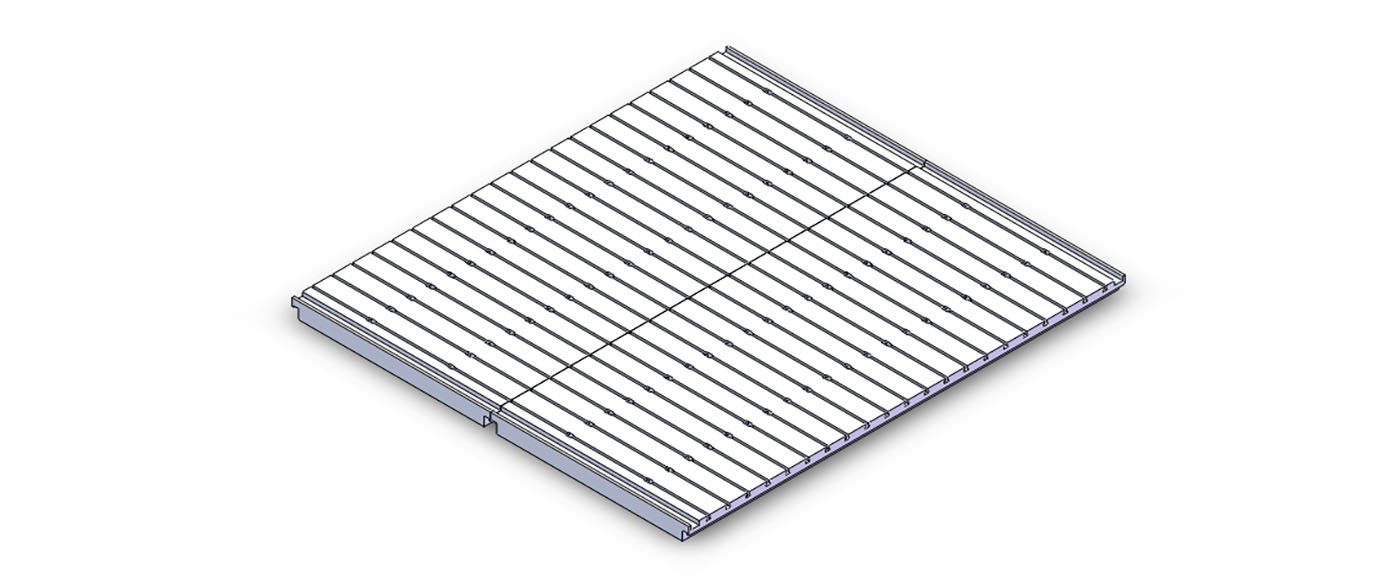

1. The machine frame body and beam are in welded fabricated structure, after enough aging heat treatment, with very good accuracy. The work table, transversal sliding table and ram all are made from cast iron. Two sides’ dual servo driving system at X axis assures the gantry’s parallel accurate movement and the good Verticality of Y axis and X axis.

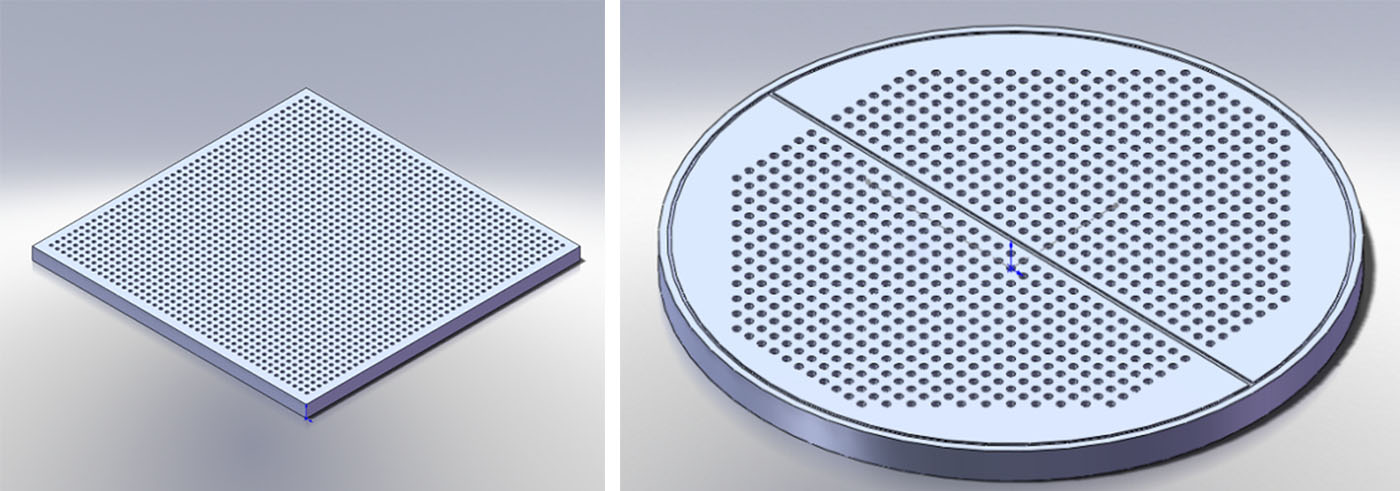

2. The work table is made from cast iron, assures stable performance.

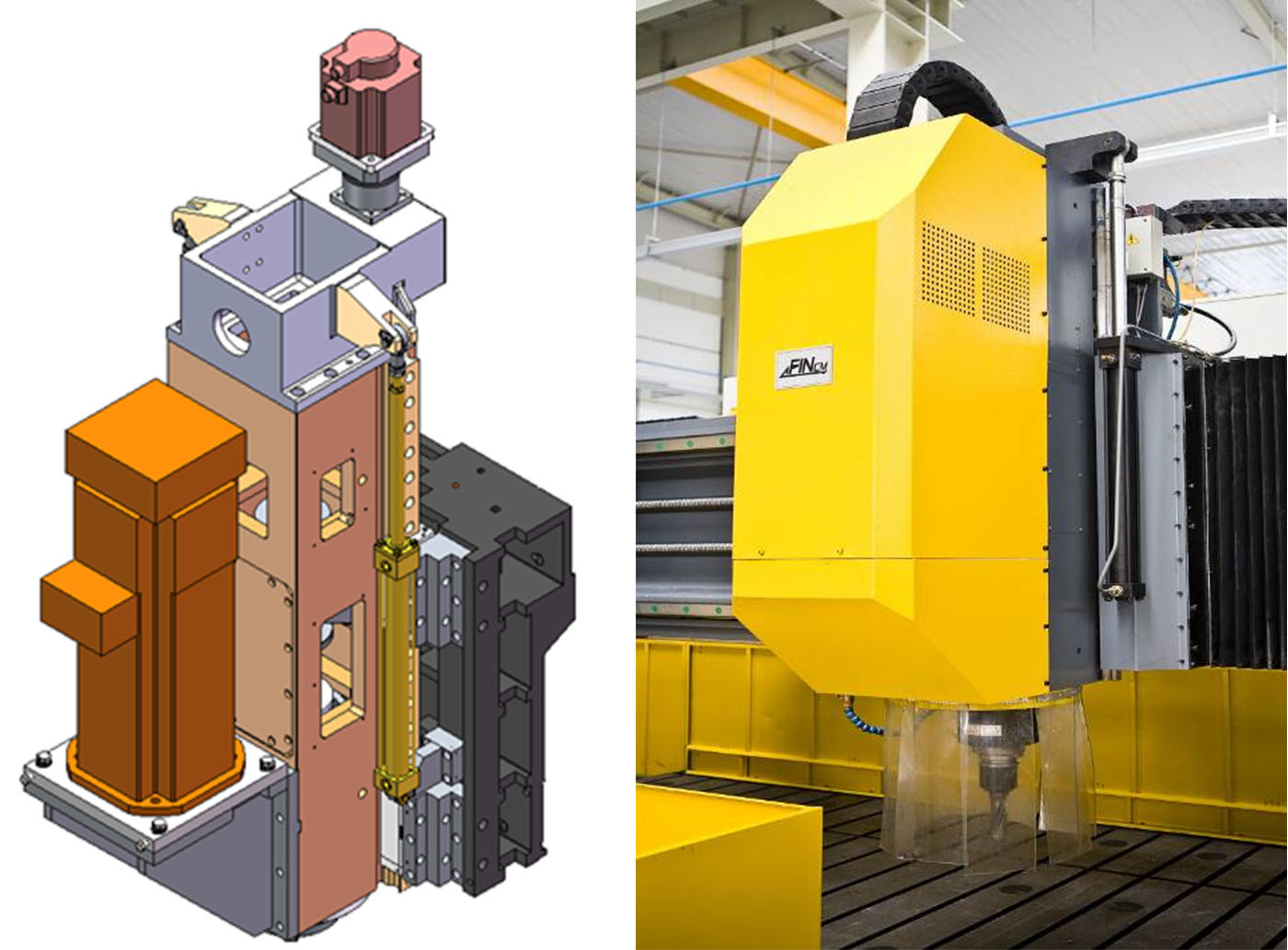

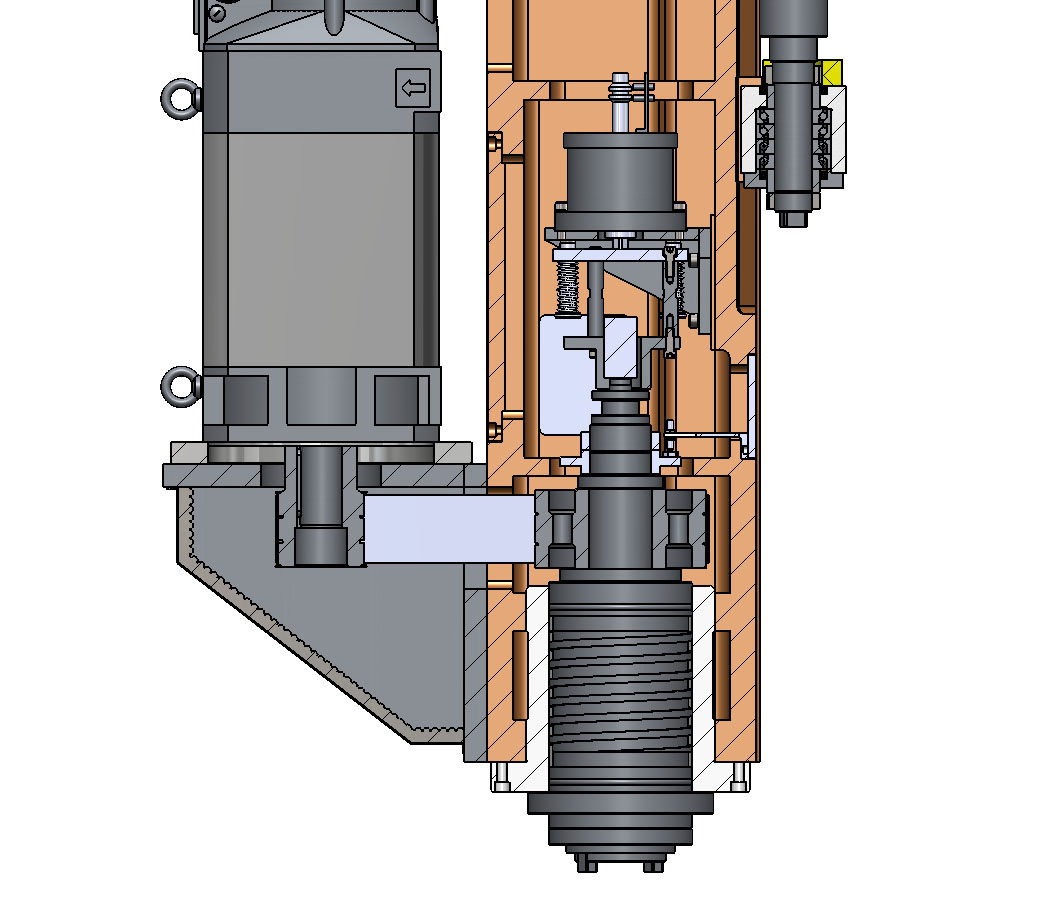

3. The Drilling spindle is rigid high precise BT50 type with internal cooling system, and easy to change tools. The spindle RPM is 30~3000r/min.

4. At the two sides of the work table there are total two plate-chain type chip removal device, the ship and cooling liquid can be collected to the device, and the coolant can be recycling used.

5. The machine has two cooling ways – internal cooling and outside cooling, enough pressure and flow rate, and there is coolant level inspection warning components, which assures enough lubricating and cooling for the drilling tool.

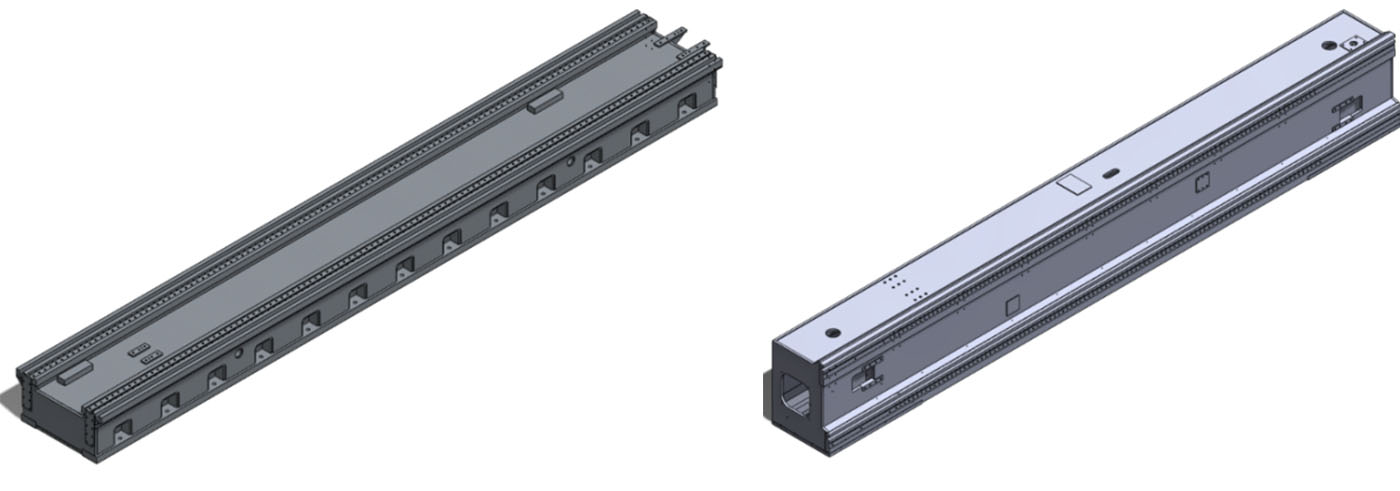

6. The machine has automatic lubricating system, provides enough and reliable lubricating for the key movement points, such as guide rail, ball screw and roller bearings, which assures the key movable components’ lifetime.

7. ATC: The linear tool magazine has 12 tools.

8. The CNC Control system is Siemens828D, with powerful function, automatic CAD-CAM programming, easy operation, automatic warning and error compensation.

Siemens CNC System

9. The key outsourced components, such as linear roller guide rail, ball screw, servo motor and servo driver, spindle, CNC system, hydraulic pump, valve and cooling pump, etc., all are from world famous brand, so the machine has very high reliability and stable performance.

Precision spindle

Chip conveyor

Cooling device

Automatic lubrication device

Key outsourced components list

|

No |

Name |

Brand |

Country |

|

1 |

Roller linear guide rail |

HIWIN/HTPM |

China Taiwan/ China Mainland |

|

2 |

CNC control system |

SIEMENS |

Germany |

|

3 |

Feeding servo motor and servo driver |

SIEMENS |

Germany |

|

4 |

Precise spindle |

SPINTECH /KENTURN |

China Taiwan |

|

5 |

Hydraulic valve |

YUKEN /JUSTMARK |

Japan/China Taiwan |

|

6 |

Oil pump |

JUSTMARK |

China Taiwan |

|

7 |

Automatic lubricating system |

HERG |

Japan |

|

8 |

Button, Indicator, Low voltage electronic components |

ABB/SCHNEIDER |

Germany/France |

Note: The above is our standard supplier. It’s subject to be replaced by same quality components of other brand if the above supplier can’t supply the components in case of any special matter.

Product detail pictures:

Related Product Guide:

To create more benefit for buyers is our business philosophy; shopper growing is our working chase for OEM China Angle Drilling Machine - PHM Series Gantry Movable CNC Plate Drilling Machine – FIN CNC , The product will supply to all over the world, such as: Salt Lake City, Oman, Rwanda, We are sticking to excellent quality, competitive price and punctual delivery and better service, and sincerely hope to establish long-term good relationships and cooperation with our new and old business partners from all over the world. Sincerely welcome you to join us.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!