2022.07.11

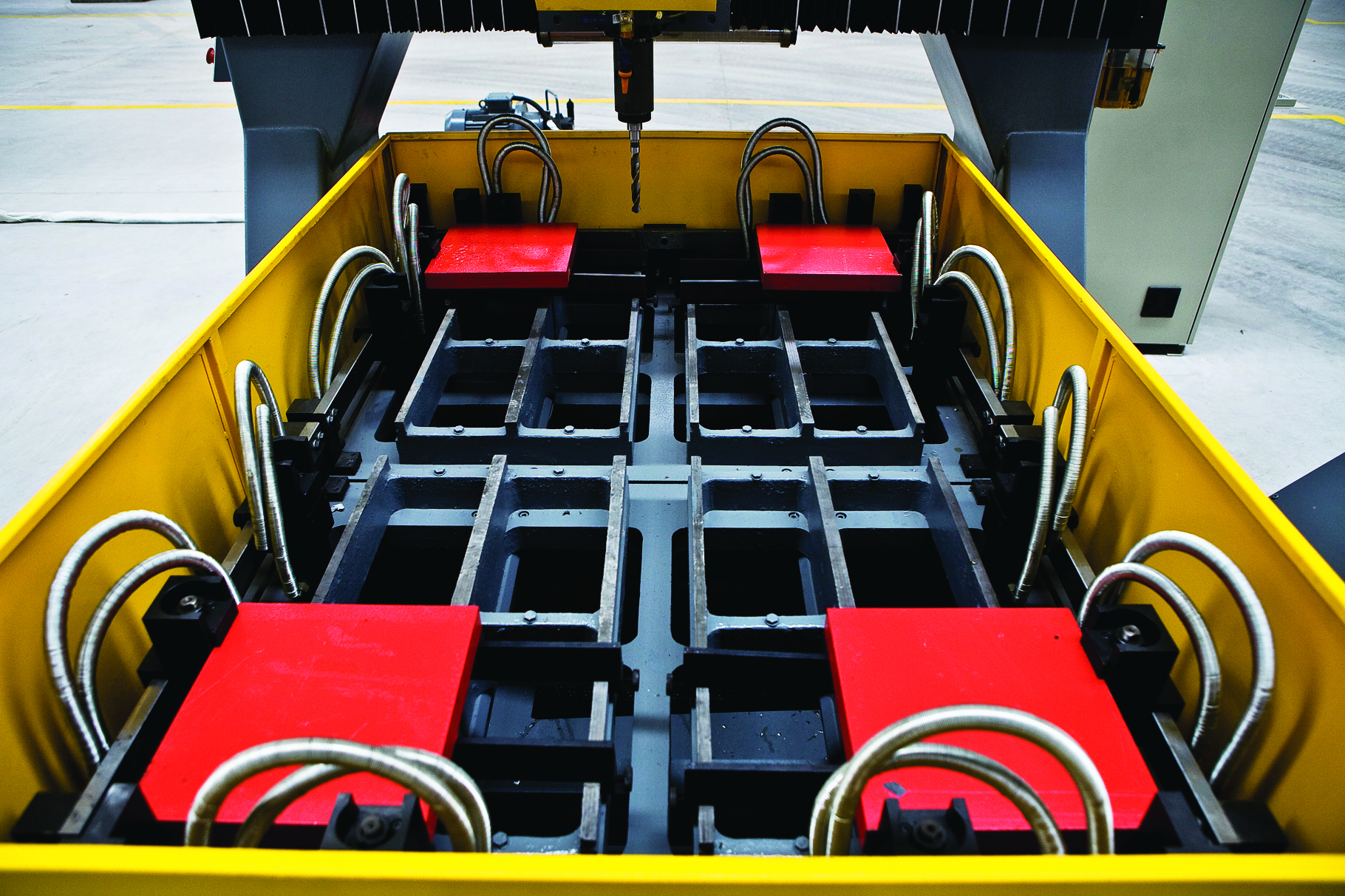

CNC Plate Drilling machine is mainly used for drilling holes on the joint plates for building, bridge, Steel tower. This machine substitutes manual lining drilling and jig drilling .It can greatly improve precision and production efficiency, shorten preparative period of producing.

Whether it is a CNC High-speed or Low-speed plate Drilling Machine, the Machine needs to be maintained and maintained. How to hold accuracy and reduce failures?

1. For the CNC drilling machine used for a long time, try not to shut down the machine during the long holiday, but press of the emergency stop.

2. Regularly check the hydraulic oil pressure in the hydraulic system, ensure that the oil gauge is not lower than rated capacity, replace the hydraulic oil every year, and the pressure of the oil pump is 6Mpa.

3. The oil return filter element and the water tank filter should be cleaned once a year.

4. Fill the water tank with coolant in time to ensure that the coolant gauge is about 100L.

5. Regularly clean or lubricate the range switch, hydraulic valve spring and other spring-loaded devices.

6. Regularly clean the CNC drill drive equipment.

7. After a long holiday, each circuit board of the machine should be manually preheated before restarting. You can heat the CNC drill with a hair dryer for a few minutes per board to get a little warmer.

The above is the method to improve the machine life, maintain the accuracy and reduce the failure in the daily use of the CNC drill. If you have any other questions, you can consult us at any time, and we will reply to you in time.

Post time: Jul-11-2022