Manufacturer for China Automatic Practical CNC Flat Bar Punching Marking Machine

Our goal is to satisfy our customers by offering golden service, good price and high quality for Manufacturer for China Automatic Practical CNC Flat Bar Punching Marking Machine, Since the manufacturing facility founded, we have now committed on the progress of new products. While using the social and economic pace, we are going to continue to carry forward the spirit of “high high-quality, efficiency, innovation, integrity”, and persist with the operating principle of “credit to start with, customer initially, top quality excellent”. We’ll make a amazing long run in hair output with our companions.

Our goal is to satisfy our customers by offering golden service, good price and high quality for China CNC Flat Bar Punching Machine, CNC Flat Bar Marking Machine, Now we have many years’ experience in hair product production, and our strict QC Team and skilled workers will ensure that we give you top hair items with the best hair quality and workmanship. You will get successful business if you choose to cooperate with such a qualified manufacturer. Welcome your order cooperation!

Product Parameters

| Item | Valve | |

| Flat bar size range | Flat bar section | 50×5~150×16mm(material Q235) |

| Flat bar raw material length | 6000mm | |

| Finished flat bar length | 3000mm | |

| Punching force | 1000kN | |

| Max. punching diameter | Round hole | φ26mm |

| Oval hole | φ22×50×10mm | |

| Punching positions number | 3(2 round holes and1oval hole) | |

| Punching hole back mark range | 20mm-80mm | |

| Shearing force | 1000KN | |

| Shearing method | Single blade shearing | |

| Number of CNC axes | 2 | |

| Feeding speed of trolley | 20m/min | |

| Machine layout type | A/B | |

| Hydraulic system | High pressure pump working pressure | 24MPa |

| Low pressure pump working pressure | 6MPa | |

| Cooling method | Water cooling | |

| Pneumatic system | Working pressure | up to 0.6MPa |

| Min 0.5MPa | ||

| Displacement of air compressor | 0.1/min | |

| Maximum pressure | 0.7MPa. | |

| Power supply | Type | Three-phase electricity |

| Voltage | 380V or as per customized | |

| Frequency | 50HZ | |

| Machine net weight | About 11000Kg | |

Details and advantages

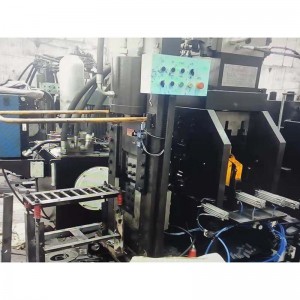

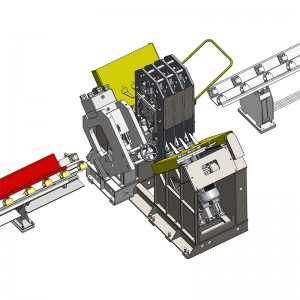

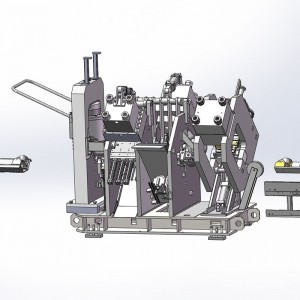

The machine is mainly composed of cross transversal conveyor, feeding conveyor, feeding trolley, main machine body, output conveyor, pneumatic system, electrical system and hydraulic system.

1. The cross transversal conveyor is a feeder for raw material flat bar, which can transfer a single piece of flat bar to the feeding area via a chain, and then slide down to the feeding conveyor.

2. The feeding conveyor is composed of supporting rack, feeding rollers, positioning roller, positioning cylinder, etc. The positioning cylinder pushes the flat bar to the positioning roller to compress and position it laterally.

3. The feeding trolley is used for clamping and feeding of flat bar, the feeding position of the trolley is controlled by the servo motor, and the trolley clamp can be lifted and lowered pneumatically.

4. The main machine is composed of flat bar positioning device, a punching unit and a shearing unit.

5. The output conveyor is used for receiving finished material, with a total length of 3 meters, and the finished material can be unloaded automatically.

6. The electrical system includes CNC system, servo, programmable controller PLC, detection and protection components, etc.

7. The hydraulic system is the power source for punching holes.

8. The machine does not need to draw lines or make a large number of templates, it can realize CAD/CAM direct conversion, and it is convenient to determine or input the size of the holes, simple to make program and operate the machine.

Key outsourced components list

| NO. | Name | Brand | Country |

| 1 | Oil Pump | Albert | United States |

| 2 | Solenoid unloading valve | Atos | Italy |

| 3 | Solenoid valve | Atos | Italy |

| 4 | Cylinder | AirTAC | Taiwan China |

| 5 | Triplex | AirTAC | Taiwan China |

| 6 | AC servo motor | Panasonic | Japan |

| 7 | PLC | Yokogawa | Japan |

Note: The above is our standard supplier. It’s subject to be replaced by same quality components of other brand if the above supplier can’t supply the components in case of any special matter.Our goal is to satisfy our customers by offering golden service, good price and high quality for Manufacturer for China Automatic Practical CNC Flat Bar Punching Marking Machine, Since the manufacturing facility founded, we have now committed on the progress of new products. While using the social and economic pace, we are going to continue to carry forward the spirit of “high high-quality, efficiency, innovation, integrity”, and persist with the operating principle of “credit to start with, customer initially, top quality excellent”. We’ll make a amazing long run in Steel Structure output with our companions.

Manufacturer for China CNC Plate Punching Machine, CNC Plate Marking Machine, Now we have many years’ experience in hair product production, and our strict QC Team and skilled workers will ensure that we give you top hair items with the best hair quality and workmanship. You will get successful business if you choose to cooperate with such a qualified manufacturer. Welcome your order cooperation!

Company Brief Profile  Factory Information

Factory Information  Annual Production Capacity

Annual Production Capacity  Trade Ability

Trade Ability