Manufacturer for Angle Steel Bending - CNC Drilling Machine for Beams – FIN CNC

Manufacturer for Angle Steel Bending - CNC Drilling Machine for Beams – FIN CNC Detail:

Product Parameters

| Item name | Parameter | |||

| BD150C-3 | BD200E-3 | |||

| Dimension of material H Beam | Maximum length of H beam | 2100mm | 1600mm | |

| Maximum size of H beam (width × height) | 1500*1500mm | 1000*2000mm | ||

| Minimum section size of H beam (width × height) | 500*500mm | 400*1000mm | ||

| Working table (Fixed) | Height of worktable from the ground | 900mm | ||

| Width of T-slot on worktable | 28mm | |||

| Gantry longitudinal movement (X-axis) | X-axis stroke | 21m | 16m | |

| X-axis servo motor power | 2×3.0kW | |||

| Lateral movement of power head on gantry beam (V-axis) | V-axis stroke | 1500mm | 1980mm | |

| V-axis servo motor power | 1.5KW | |||

| Vertical movement of power head on double column of gantry (U-axis, W-axis) | U-axis, W-axis stroke | 1500mm | 980mm | |

| U-axis, W-axis servo motor power | 2×1.5kW | |||

| Table type drilling (sliding head) | Quantity | 3 | ||

| Maximum hole drilling diameter | 12~50 | |||

| Spindle RPM (frequency conversion 30-100Hz) | 120-400r/min | 120-560r/min | ||

| Morse taper of spindle | 4 | 8 | ||

| Spindle motor power | 3×7.5kW | |||

| Axial stroke (1 axis, 3 axis) | 600mm | 780mm | ||

| Axial stroke (2-axis) | 700mm | 580mm | ||

| 1-axis, 2-axis, 3-axis drive mode | AC servo motor, ball screw drive | |||

| 1-axis, 2-axis, 3-axis feed rate | 0-4000mm/min | |||

| 1-axis, 2-axis, 3-axis servo motor power | 3×1.5kW | |||

| Motor power of hydraulic pump | 3+4kW | |||

| Chip removal and cooling | Chip conveyor type | Flat chain | ||

| Chip removal speed | 1m/min | |||

| Chip conveyor motor power | 2×0.75KW | |||

| Cooling pump motor power | 0.45KW | |||

| Electrical system | Numerical control system | PLC | ||

| Number | 8 | |||

| Total power of machine tool | About 47kw | |||

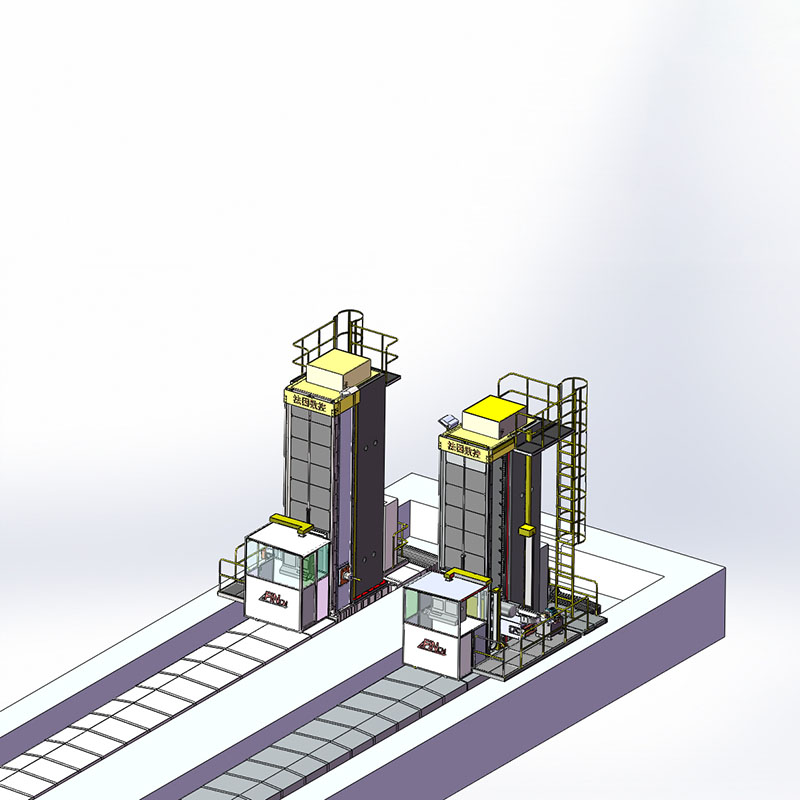

| Overall dimension (L × W × H) |

About 26m × 4.5 m× 4.2m | |||

| Weight | About 60tons | |||

Details and advantages

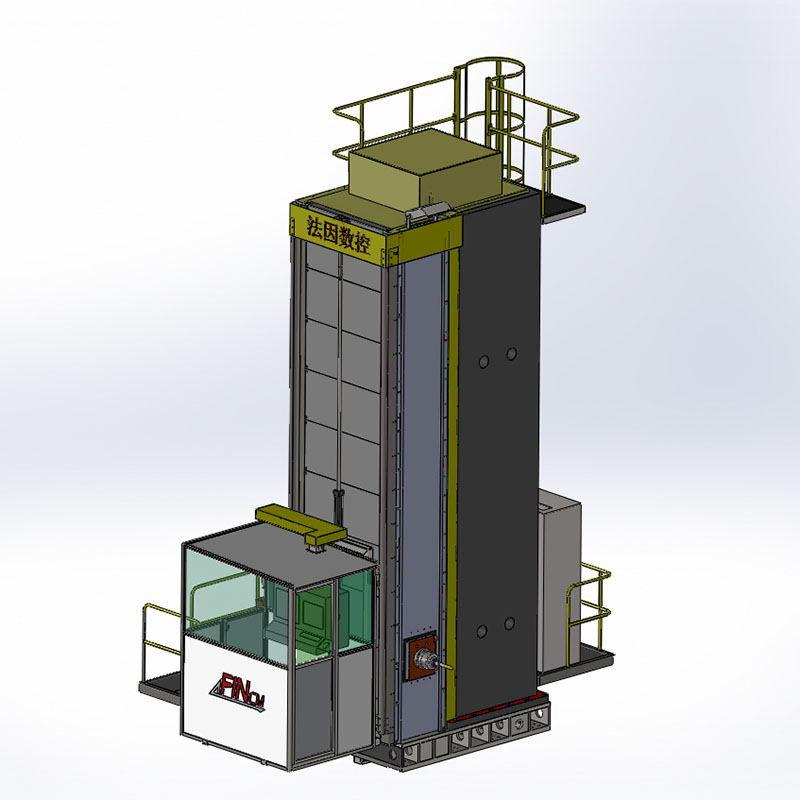

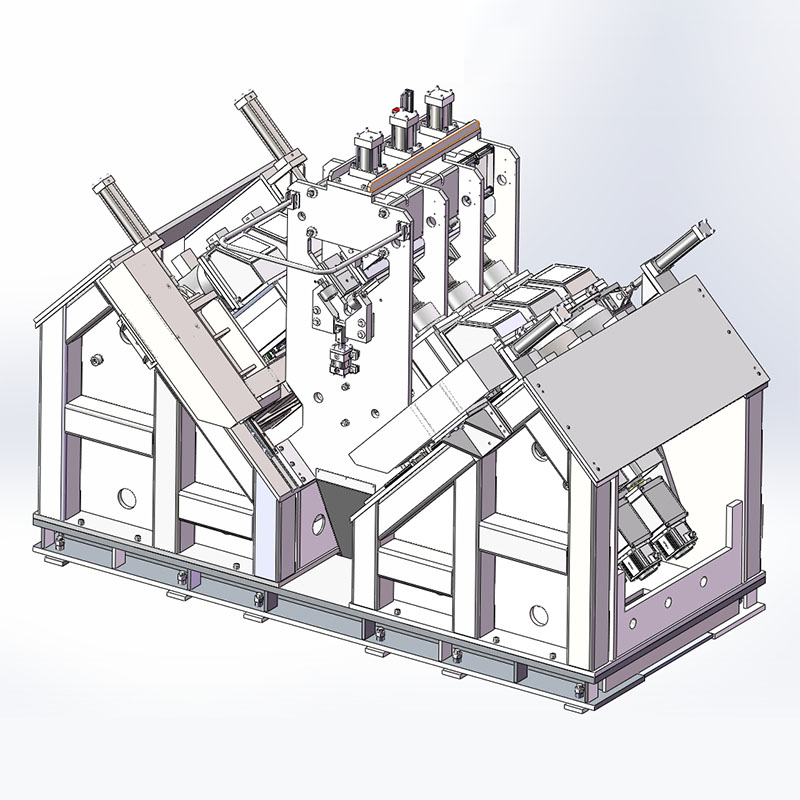

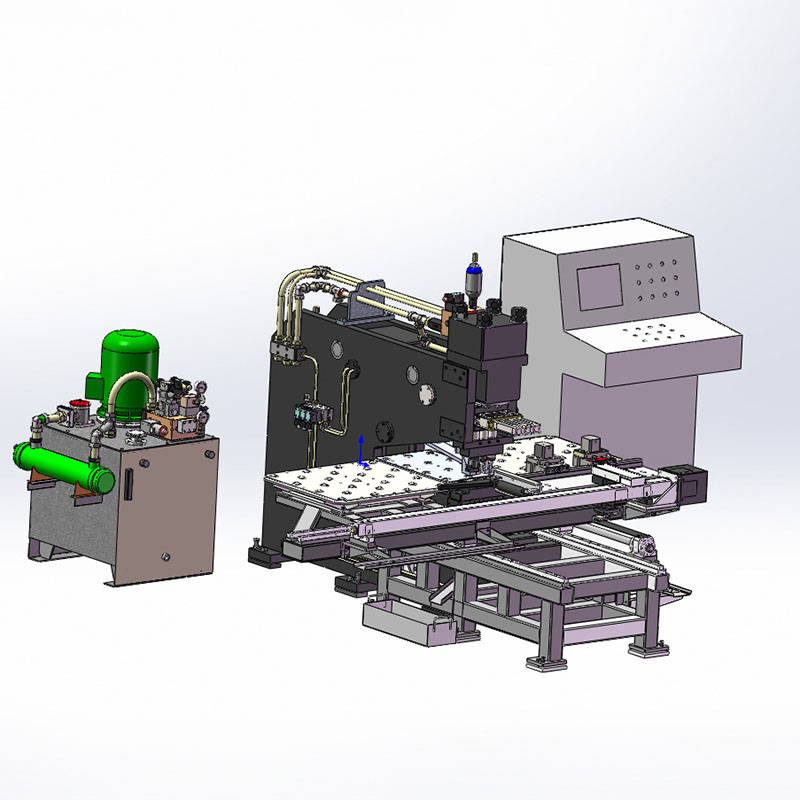

1. The machine is mainly composed of bed, gantry, headstock, electrical system, hydraulic system, cooling chip removal system, detection system, etc.

2. The machine adopts the structure of gantry moving and fixed worktable, which can reduce the bed length and save the floor area.

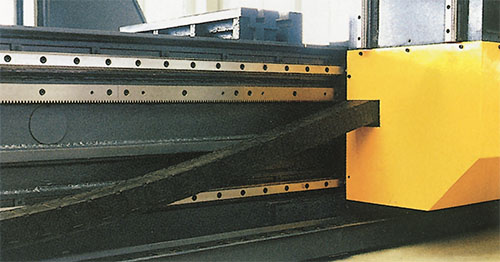

3. The gantry motion (x-axis) is driven by linear ball guide, AC servo motor and low backlash rack and pinion. Linear ball guide, AC servo motor and ball screw drive are used to guide the movement of gantry crossbeam and sliding plate on two vertical columns (U, V, W). The feed motion of each drilling head (Axis 1, 2 and 3) is guided by linear roller guide, driven by servo motor and ball screw.

4. The spindle adopts the CNC feed drilling power head produced by our company.

5. The bottom of the machine is equipped with a flat chain type chip remover, and the chip conveyor is equipped with a water pump and a cooling liquid filtration circulating device.

6. The hydraulic system is mainly used for X-axis positioning and locking and balancing of power heads on both sides.

7. The electrical system is controlled by PLC and equipped with upper computer. The material is input and stored by computer, so it is easy to operate.

Key outsourced components list

|

NO. |

Name |

Brand |

Country |

|

1 |

Linear ball guide pair |

HIWIN/PMI |

Taiwan, China |

|

2 |

PLC |

Mitsubishi |

Japan |

|

3 |

Servo motor and driver |

Mitsubishi / Panasonic |

Japan |

|

4 |

Hydraulic valve |

ATOS |

Italy |

|

5 |

Oil pump |

Justmark |

Taiwan, China |

|

6 |

Button, indicator light |

Schneide |

France |

|

7 |

Drag chain |

JFLP |

China |

Note: The above is our standard supplier. It’s subject to be replaced by same quality components of other brand if the above supplier can’t supply the components in case of any special matter.

Product detail pictures:

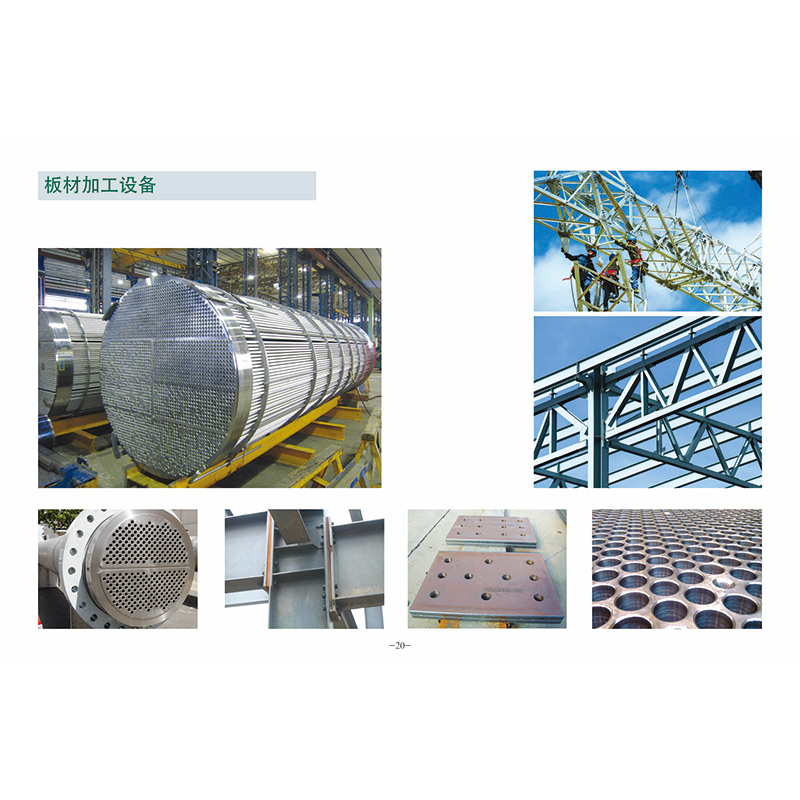

Related Product Guide:

We've got a specialist, effectiveness staff to supply high quality service for our shopper. We always follow the tenet of customer-oriented, details-focused for Manufacturer for Angle Steel Bending - CNC Drilling Machine for Beams – FIN CNC , The product will supply to all over the world, such as: Mali, Amman, Poland, With the effort to keep pace with world's trend, we'll always endeavor to meet customers' demands. If you want develop any other new items, we can customize them to suit your needs. If you feel interest in any of our products and solutions or want develop new merchandise, you should feel free to contact us. We are looking forward to forming successful business relationship with customers all over the world.

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.