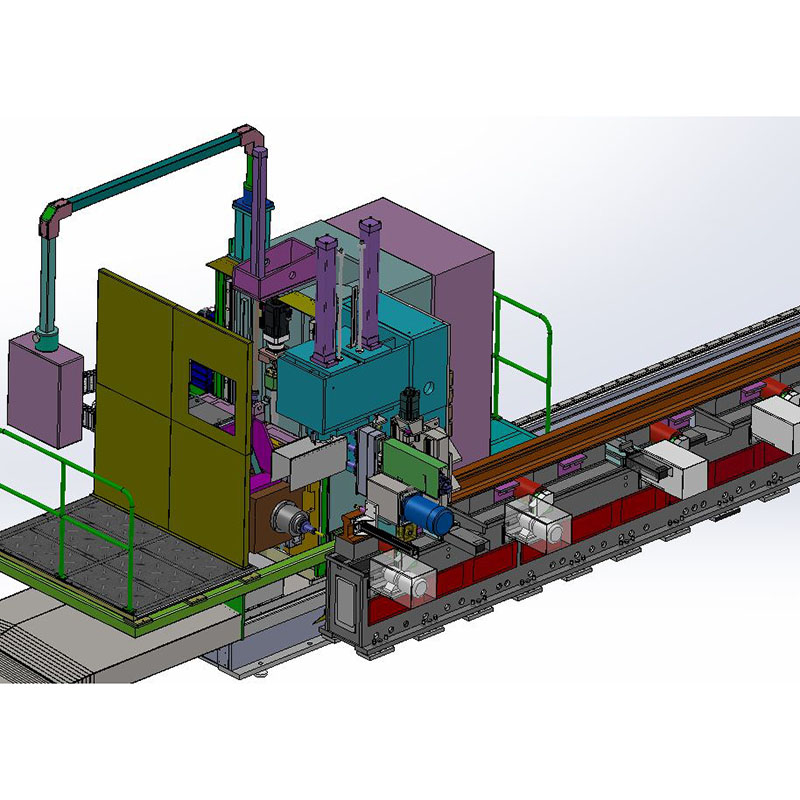

Hot sale CNC Milling Machine Vertical - APM1010 CNC Angle Steel Punching Shearing Machine – FIN CNC

Hot sale CNC Milling Machine Vertical - APM1010 CNC Angle Steel Punching Shearing Machine – FIN CNC Detail:

Product Parameters

| NO. | Item | Parameters |

| 1 | Angle size | 40x40x3~100x100x10mm |

| 2 | Max. raw material angle profile length | 12m |

| 3 | Max. punching capacity (Hole Diameter x Material Thickness mm) |

Φ25.5mm x10mm |

| 4 | Nominal punching force | 440KN |

| 5 | Nominal marking force | 1030KN |

| 6 | Nominal cutting force | 1100KN |

| 7 | No. of character group | 4 |

| 8 | No. of character in each character group | 18 |

| 9 | Character size | 14x10x19mm |

| 10 | Cutting mode | Single-blade shearing |

| 11 | Range of stadia | 20~170 (stepless) |

| 12 | No. of punch on each side | 2 |

| 13 | Max. feeding speed | 60m/min |

| 14 | No. of CNC axes | 3 |

| 15 | Overall size | 25x7x2.2m |

| 16 | Total power | About 31.4KW |

| 17 | Machine weight | Approx. 13800Kg |

Details And Advantages

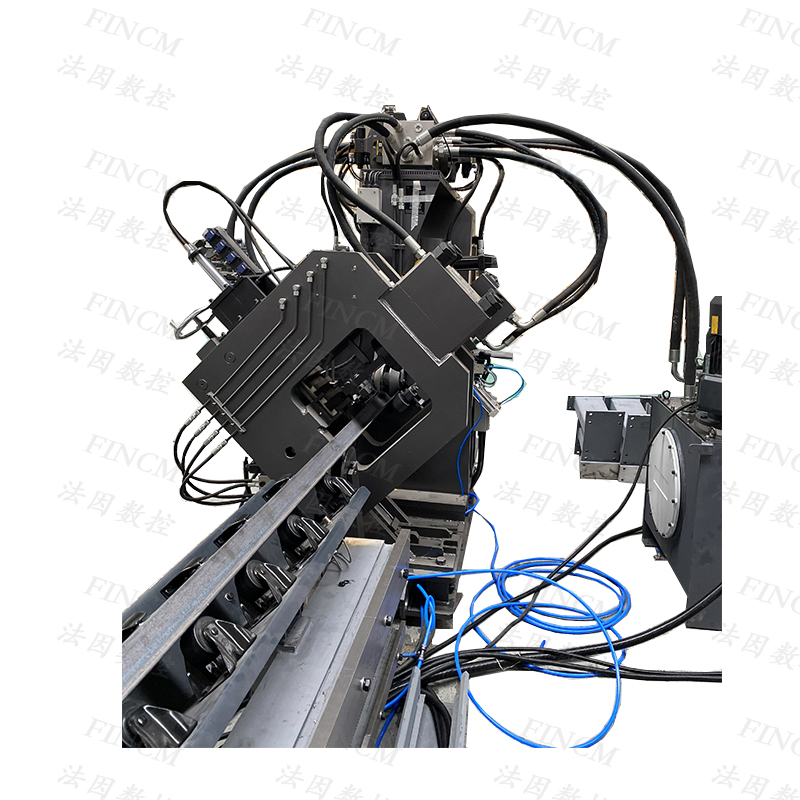

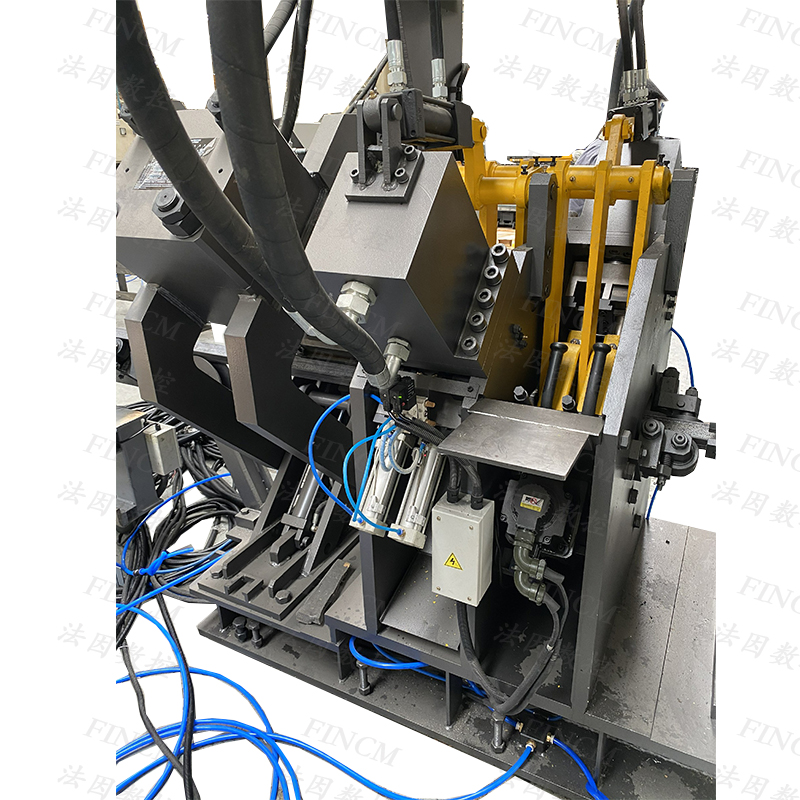

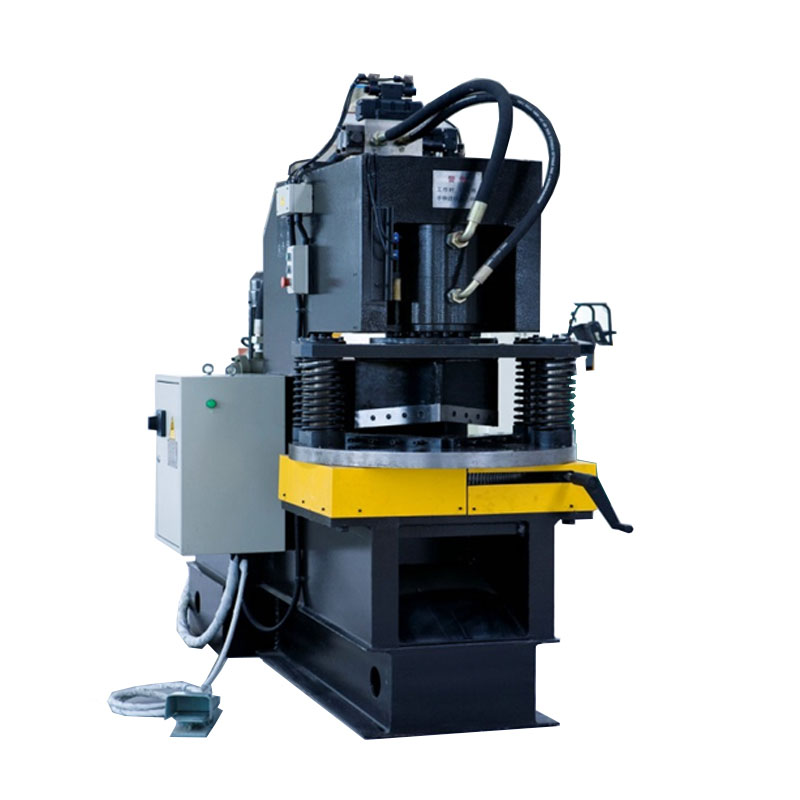

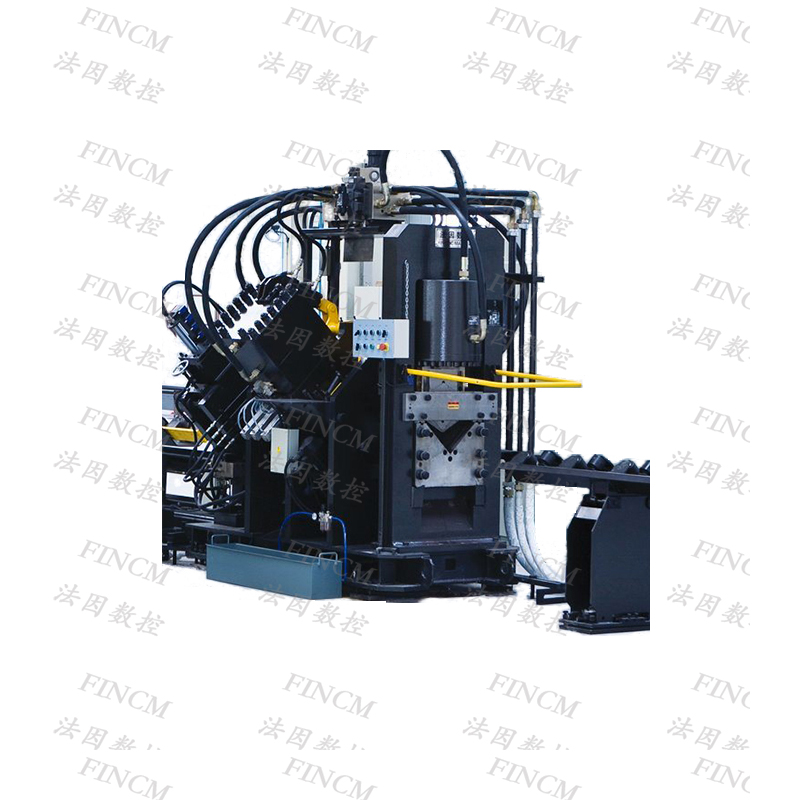

1、Punching unit adopts closed structure frame, which is very rigid.

2、The single blade cutting mechanism ensures that the cutting section is neat and the shearing clearance is easy to adjust.

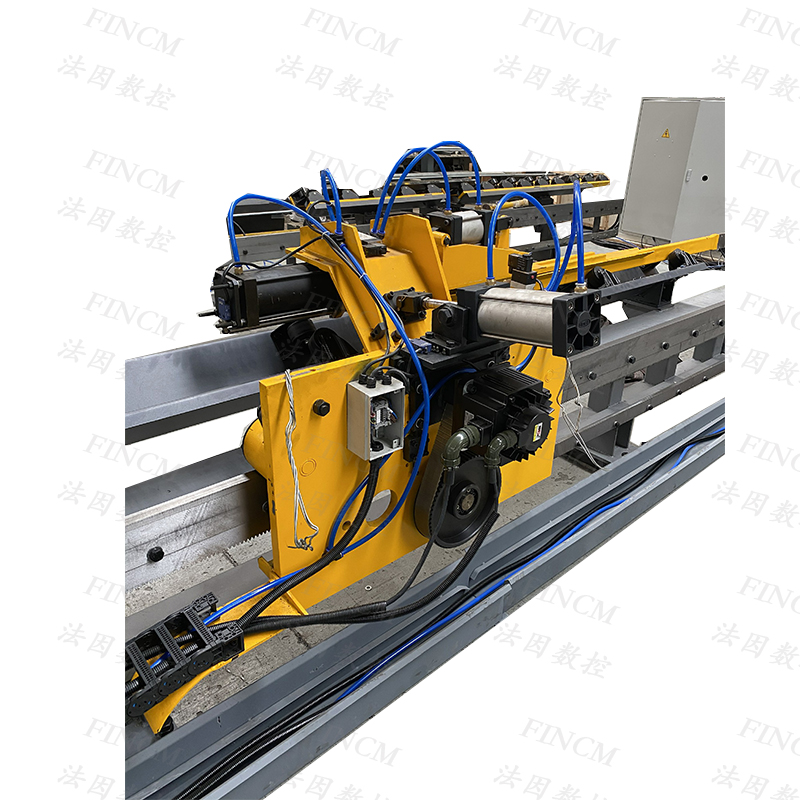

3、The CNC feeding trolley is clamped by pneumatic clamp to move and position rapidly. The angle is driven by servo motor, driven by rack and pinion and linear guide, with high positioning accuracy

4、This machine has a CNC axis: the movement and positioning of the feeding This machine has a CNC axis: the movement and positioning of the feeding gripper carriage.

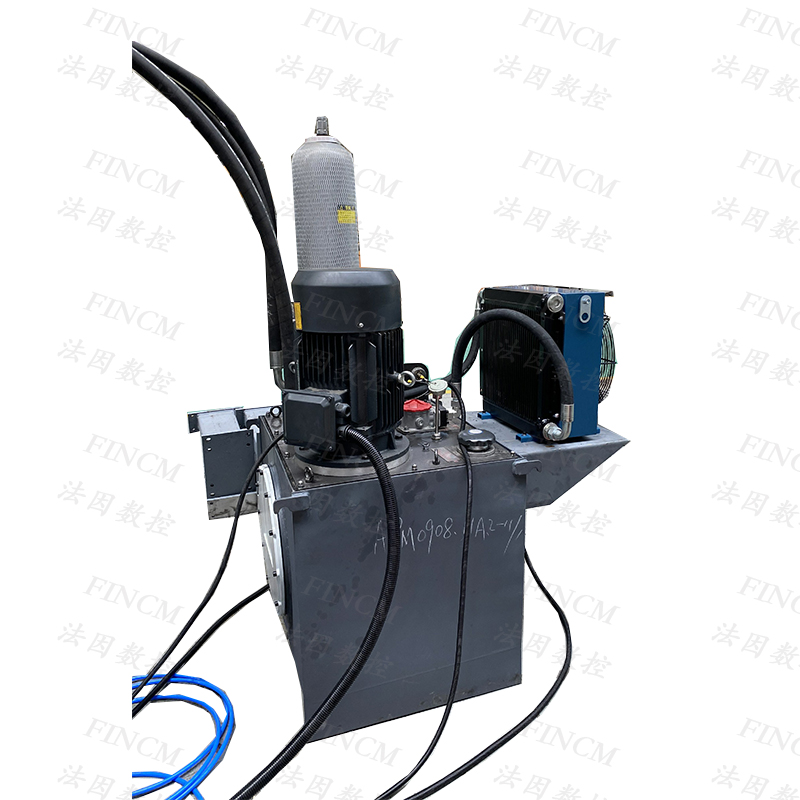

5、The hydraulic pipeline adopts the ferrule structure, which effectively reduces the oil leakage and improves the stability of the machine.

6、It is easy to program by computer. It can display the workpiece figure and the coordinate size of the hole position, so it is easy to check. It is very convenient to store and call the program, to display the graph, to diagnose the fault and to communicate with the computer.

Key Outsourced Components List

|

NO. |

Name |

Brand |

Origin Country |

|

1 |

AC Servo Motor |

DELTA |

China Taiwan

|

|

2 |

PLC |

DELTA |

|

|

3 |

Electromagnetic unloading valve |

ATOS/YUKEN |

Italy/China Taiwan

|

|

4 |

Relief valve |

ATOS/YUKEN |

|

|

5 |

Electro-hydraulic directional valve |

JUSTMARK |

China Taiwan |

|

6 |

Vane pump |

ALBERT |

USA |

|

7 |

Manifold |

AirTAC |

China Taiwan

|

|

8 |

Air Valve |

AirTAC |

|

|

9 |

Cylinder |

SMC/CKD |

Japan

|

|

10 |

Duplex |

SMC/CKD |

|

|

11 |

Computer |

Lenovo |

China |

Note: The above is our fixed supplier. It’s subject to be replaced by same quality components of other brand if the above supplier can’t supply the components in case of any special matter.

Product detail pictures:

Related Product Guide:

Now we have superior devices. Our solutions are exported to your USA, the UK and so on, enjoying a superb name between customers for Hot sale CNC Milling Machine Vertical - APM1010 CNC Angle Steel Punching Shearing Machine – FIN CNC , The product will supply to all over the world, such as: Cancun, Austria, Sierra Leone, We'll initiate the second phase of our development strategy. Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. If you are interested in any of our products and solutions or would like to discuss a custom order, make sure you feel free to contact us. We've been looking forward to forming successful business relationships with new clients around the world in the near future.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!