Hot sale Band Saw For Steel – BHD1206A/3 FINCM U Channel Steel Structure CNC High Speed Drilling Machine – FIN CNC

Hot sale Band Saw For Steel – BHD1206A/3 FINCM U Channel Steel Structure CNC High Speed Drilling Machine – FIN CNC Detail:

Product Parameters

|

No. |

Item name |

Parameters |

|

|

1 |

H-beam |

Section height |

150~1250mm |

|

Flange width |

75~600mm |

||

|

2 |

U-shaped steel |

Section height |

150~1250mm |

|

Flange width |

75~300mm |

||

|

3 |

Workpiece length |

|

1500 ~15000mm |

|

4 |

Maximum thickness of workpiece |

|

75mm |

|

5 |

Drilling power box |

Quantity |

3 |

|

6 |

Maximum borehole diameter |

Cemented carbide¢ 30mm High-speed steel¢ 40mm |

|

|

Spindle taper hole |

BT40 |

||

|

Spindle motor power |

3*11KW |

||

|

Spindle speed (stepless speed regulation) |

20~2000r/min |

||

|

7 |

CNC axis |

Quantity |

6 |

|

Servo motor power of fixed side, moving side and middle side feed shaft |

3×2kW |

||

|

Fixed side, moving side, middle side, moving side positioning axis servo motor power |

3×1.5kW |

||

|

Moving speed of three positioning CNC axes |

0~10m/min |

||

|

Moving speed of three feed CNC axes |

0~5m/min |

||

|

Left and right horizontal distance of middle side |

40~760 mm |

||

|

Width detection stroke |

1100mm |

||

|

8 |

Web detection stroke |

290mm |

|

|

9 |

Feeding trolley |

Power of servo motor of feeding trolley |

5kW |

|

Maximum feeding speed |

20m/min |

||

|

Maximum feeding weight |

10t |

||

|

10 |

Cooling system |

Compressed air pressure required |

0.8Mpa |

|

Number of nozzles |

3 |

||

|

Cooling mode |

Internal cooling + external cooling |

||

|

11 |

Accuracy |

Error of adjacent hole spacing in hole group |

±0.4mm |

|

Accuracy error of 10m feeding |

±1.0 |

||

|

12 |

Overall dimensions of main engine (L x W x H) |

Aboutn 6.0*1.6*3.4 m |

|

|

13 |

Main engine weight |

About 8000kg |

|

Details and Advantages

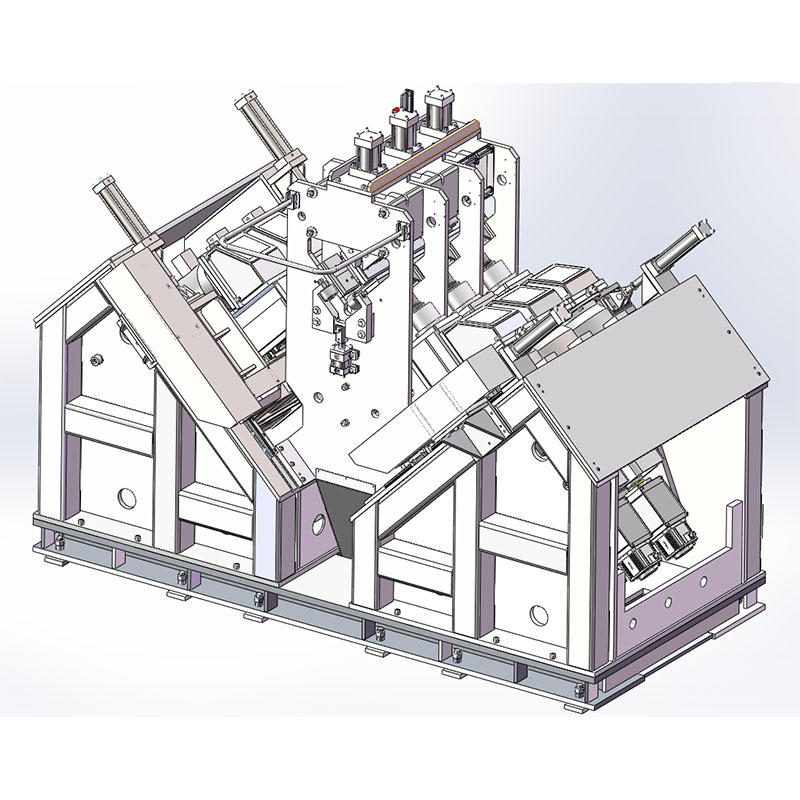

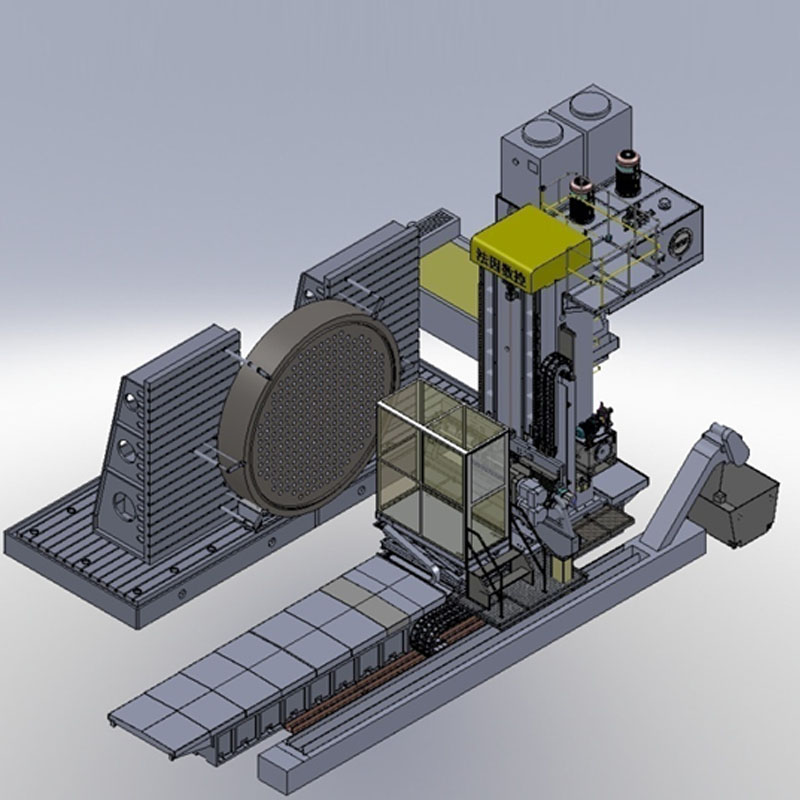

1、The drilling machine is mainly composed of bed, CNC sliding table (3), drilling spindle (3), clamping device, detection device, cooling system, scrap iron box, etc.

2、There are three CNC sliding tables, which are fixed side CNC sliding table, mobile side CNC sliding table and middle CNC sliding table. The three sliding tables are composed of sliding plate, sliding table and servo drive system. There are six CNC axis on the three sliding tables, including three feed CNC axes and three positioning CNC axes. Each CNC axis is guided by precision linear rolling guide and driven by AC servo motor and ball screw, which ensures its positioning accuracy.

Key Outsourced Components

|

No. |

Name |

Brand |

Country |

|

1 |

Principal axis |

Keturn |

Taiwan, China |

|

2 |

Linear rolling guide pair |

HIWIN/CSK |

Taiwan, China |

|

3 |

Hydraulic pump |

JUSTMARK |

Taiwan, China |

|

4 |

Electromagnetic hydraulic valve |

ATOS/YUKEN |

Italy / Japan |

|

5 |

Servo motor |

Siemens / MITSUBISHI |

Germany / Japan |

|

6 |

Servo driver |

Siemens / MITSUBISHI |

Germany / Japan |

|

7 |

Programmable controller |

Siemens / MITSUBISHI |

Germany / Japan |

|

8 |

computer |

Lenovo |

China |

Note: The above is our fixed supplier. It’s subject to be replaced by same quality components of other brand if the above supplier can’t supply the components in case of any special matter.

Product detail pictures:

Related Product Guide:

We hold strengthening and perfecting our items and repair. At the same time, we get the job done actively to do research and progress for Hot sale Band Saw For Steel – BHD1206A/3 FINCM U Channel Steel Structure CNC High Speed Drilling Machine – FIN CNC , The product will supply to all over the world, such as: Turkey, Honduras, Cannes, We'd like to invite customers from abroad to discuss business with us. We can provide our clients with high quality products and excellent service. We are sure that we will have good cooperative relationships and make a brilliant future for both parties.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!