High Quality CNC Angle Line - Steel Structure Beam Drilling and Sawing Combined Machine Line – FIN CNC

High Quality CNC Angle Line - Steel Structure Beam Drilling and Sawing Combined Machine Line – FIN CNC Detail:

Product Parameters

| NO | Item | Parameter | ||||||||

| DLS400 | DMS700 | DMS1206A | DMS1250 | |||||||

| 1 | Plate size | H-beam | Web height | 100mm~400mm | 150~700mm | 150~1250mm | 150~1250mm | |||

| 2 | Flange width | 75mm~300mm | 75~400mm | 75~600mm | ||||||

| 3 | Channel steel | Height | 126mm~400mm | 150~700mm | 150~1250mm | 126~400mm | ||||

| 4 | Leg width | 53mm~104mm | 75~200 mm | 75~300mm | 53~104mm | |||||

| 5 | Minimum length of automatic feeding | 1500mm | 1500mm | |||||||

| 6 | Maximum feeding length | 12000mm | 12000mm | |||||||

| 7 | Maximum weight | 1500kg | 1500kg | |||||||

| 8 | Spindle | Number of drilling headstocks | 3 | |||||||

| 9 | Number of spindles per drilling headstock | 3 | ||||||||

| 10 | Drilling range of headstock on both sides | ¢12.5mm~¢30mm | 12.5~30 mm | |||||||

| 11 | Middle drilling range | ¢12.5mm~¢40mm | 12.5~40 mm | |||||||

| 12 | Spindle speed(RPM) | 180r/min~560r/min | 20~2000r/min | 180~560 r/min | ||||||

| 13 | Drill clamping form | Morse No. 4 | ||||||||

| 14 | Axial feed speed | 20mm/min-300mm/min | 20~300 mm/min | |||||||

| 15 | CNC axis | Feeding CNC Axis | Servo motor power | 4kw | 5kW | 4kw | ||||

| 16 | Maximum speed | 40m/min | 20m/min | 40 m/min | ||||||

| 17 | The upper unit moves horizontally | Servo motor power | 1.5kw | 1.5kw | ||||||

| 18 | Maximum speed | 10m/min | 10 m/min | |||||||

| 19 | Fixed side and mobile side move vertically | Servo motor power | 1.5kw | 1.5 kw | ||||||

| 20 | Maximum speed | 10m/min | 10 m/min | |||||||

| 21 | Host size | 4377x1418x2772mm | 6000×2100×3400mm | 4377x1418x2772mm | ||||||

| 22 | Host weight | 4300kg | 7500kg | 8500kg | 4300kg | |||||

| Main technical parameters of sawing unit: | ||||||||||

| Plate size | Maximum | 500×400 mm | 700 ×400 mm | 1250 ×600 mm | 500×400 mm | |||||

| Minimum | 150 mm×75 mm | 500x 500mm | 100×75mm | |||||||

| Sawing blade | T:1.3mm | T:1.3mm W:41mm | T:1.6mm W:67mm |

T:1.3mm W:41mm |

||||||

| Motor power | Main motor | 5.5 kW | 7.5 kw | 15 kw | 5.5 kw | |||||

| Hydraulic | 2.2kW | 2.2kw | ||||||||

| Saw blade linear speed | 20~80 m/min | 20~80 m/min | ||||||||

| Saw blade cutting feed speed | Program control | |||||||||

| Working table height | 800 mm | 800 mm | ||||||||

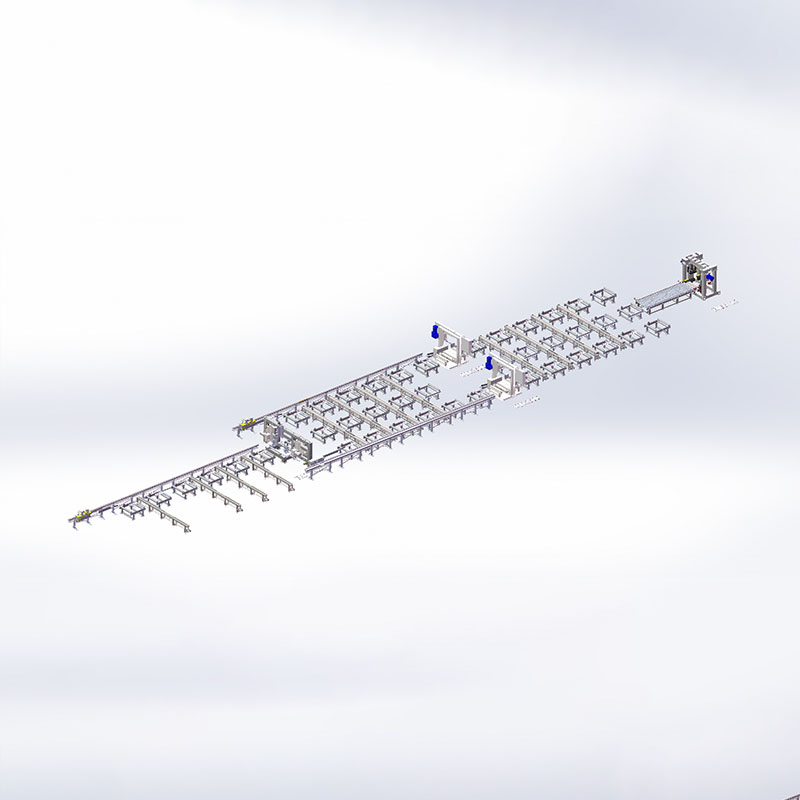

Machine composition

| NO | QTY | DLS400 | DMS700 | DMS1206A | DMS1250 |

| 1 | 1 set | Feeding support rolling table | Feed side transverse channel | Transversal Loading bed for feeding material | Feeding support rolling table |

| 2 | 1 set | Feeding trolley | Feeding support roller table | Feeding supporting rollers | Feeding trolley |

| 3 | 1 set | Three-dimensional CNC drilling machine(SWZ400/9) | Feeding trolley | Feeding pincher | Three-dimensional CNC drilling machine(SWZ1250C) |

| 4 | 1 set | Corner band saw machine(DJ500) | BHD700 / 3 CNC 3D drilling machine | Drilling machine | Corner band saw machine(DJ1250) |

| 5 | 1 set | Discharge support rolling table | M1250 marking machine | Cutting saw machine | Discharge support rolling table |

| 6 | 1 set | Electric systems | DJ700 CNC angle band sawing machine | Output supporting rollers | Electric systems |

| 7 | 1 set | Discharge support roller table | Electrical control system | ||

| 8 | 1 set | Electrical system |

Details and advantages

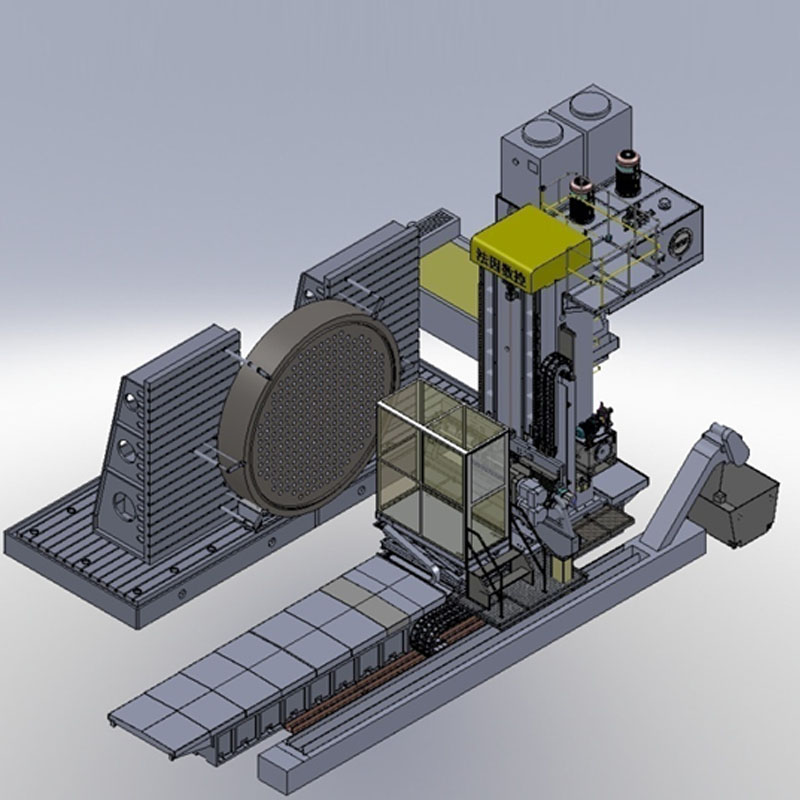

1. Strong Machine Frame Body Fabricated by strong welded steel plate and steel profile, after enough heat treatment procedure, with good enough rigidity and quite reliable performance.

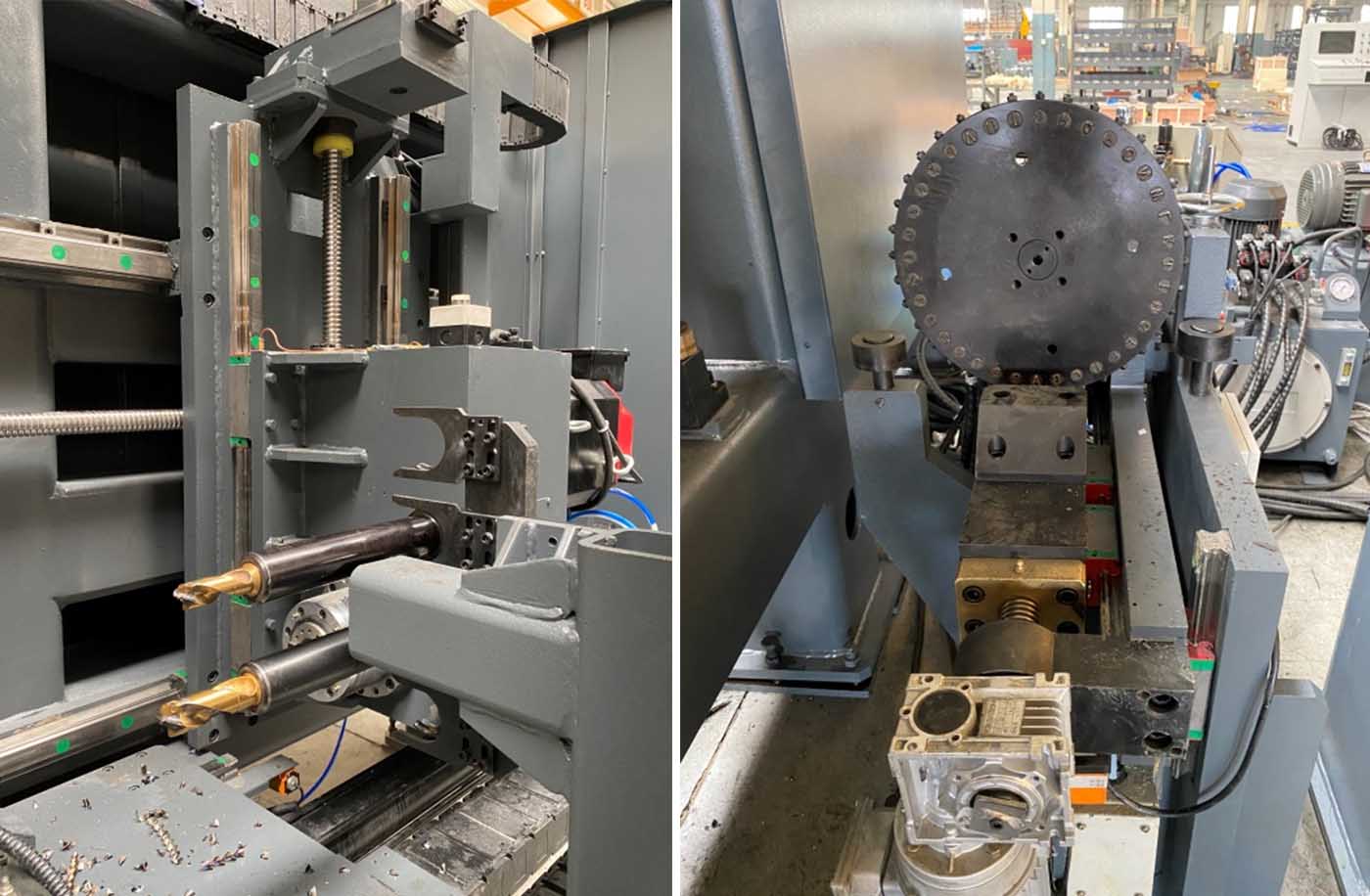

2. High work accuracy Three CNC Axis Very high accuracy: The two side spindles up & down movement (The fixed spindle side and the movable spindle side) and the Up side’s horizontal movement, all 3 CNC Axis’s high accuracy are assured by good quality famous world brand linear guide rail + AC servo motor + Ball screw.

3. Automatic measuring device for web height and flange width. The automatic web height and flange width measuring device can compensate the drilling operation’s tolerance if any caused by irregular contour of material profile, which assures higher working accuracy.

4. High Feeding material position accuracy There is photoelectric focusing switch at the feeding portal of the machine, fast get the benchmark at feeding direction, it can assure very high feeding position accuracy even after long time’s operation.

5. Advanced convenient electric control software The software can automatically create processing program by directly reading the drawing (with stipulated format), the operator just needs to simply input the material size, without complicated program edition, which is very convenient for machine’s operation, greatly improves the production efficiency.

Key Outsourced Components List

| No. | Name | Band | Country |

| 1 | PLC | Inowance | China |

| 2 | Linear guides | HIWIN/CSK | Taiwan |

| 3 | Servo motor | Inowance | China |

| 4 | Server driver | Inowance | China |

| 5 | Control valve | ATOS | Italy |

| 6 | Hydraulic valve | ATOS/Yuken | Italy |

| 7 | Hydraulic pump | Justmark | Taiwan |

| 8 | Hydraulic valve | Yuken/Justmark | Japan/Taiwan |

| 9 | Linear guides | HIWIN/PMI | Taiwan |

| 10 | Band saw blade | WIKUS/Renault | German/USA |

Product detail pictures:

Related Product Guide:

To continuously increase the administration process by virtue of the rule of "sincerely, good religion and excellent are the base of company development", we commonly absorb the essence of linked goods internationally, and continually build new solutions to fulfill the requires of shoppers for High Quality CNC Angle Line - Steel Structure Beam Drilling and Sawing Combined Machine Line – FIN CNC , The product will supply to all over the world, such as: Borussia Dortmund, Istanbul, Slovakia, Our products are widely recognized and trusted by users and can meet continuously changing of economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.