High Quality CNC Angle Line - PHD3016&PHD4030 CNC High-speed Drilling Machine for Steel Plates – FIN CNC

High Quality CNC Angle Line - PHD3016&PHD4030 CNC High-speed Drilling Machine for Steel Plates – FIN CNC Detail:

Product Parameters

| Specification name | Items | Specification valve | |

| PHD3016 | PHD4030 | ||

| Plate dimension | Material overlapping thickness | Max. 100mm | |

| Width ×length | 3000*1600mm | 4000*3000mm | |

| Spindle | Spindle boring | BT50 | |

| Drill hole diameter |

Ordinary H.S.S. drill maximum Φ50mm Carbide drill maximum Φ40mm |

||

| Rotate speed | 0-2000r/min | ||

| Travel length | 350mm | ||

| Spindle frequency conversion motor power | 15KW | ||

| Plate clamp | Clamp thickness | 15-100mm | |

| Clamp force | 7.5kN | ||

| Motor Power | Hydraulic pump | 2.2kW | |

| X axle servo system | 2.0kW | ||

| Y axle servo system | 1.5kW | ||

| Z axle servo system | 2.0 KW | ||

| Chip conveyor | 0.75kW | ||

| Travel range | X axle | 3000mm | 4000mm |

| Y axle | 1600mm | 3000mm | |

| Z axle | 350mm | ||

Details and advantages

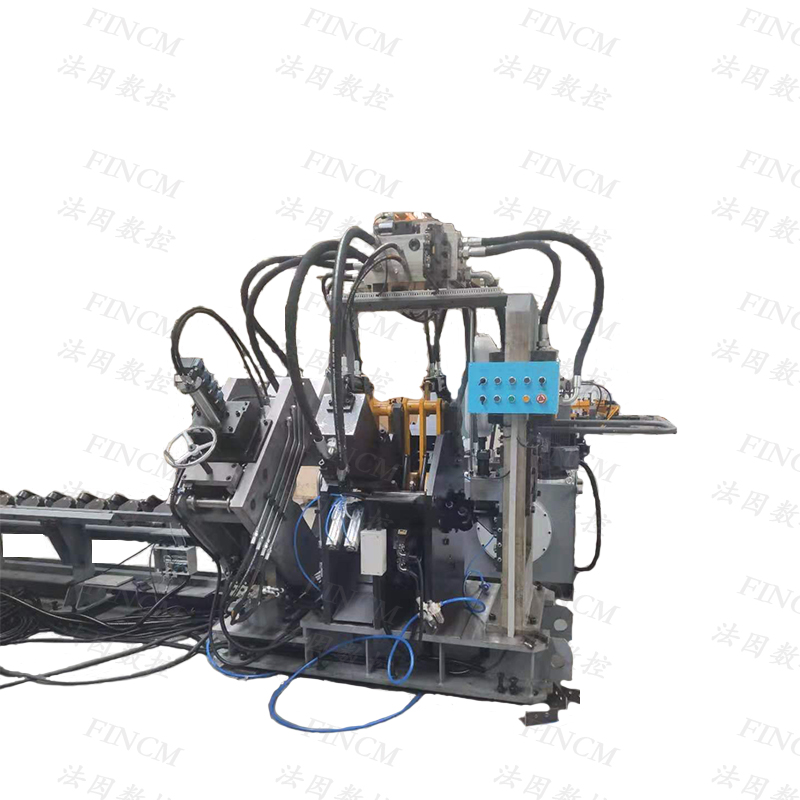

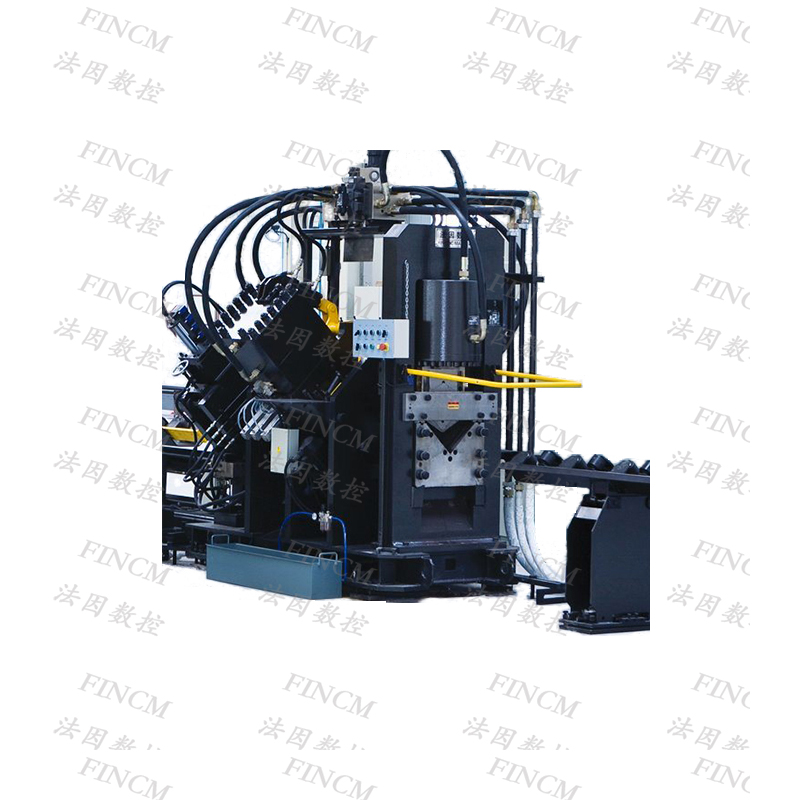

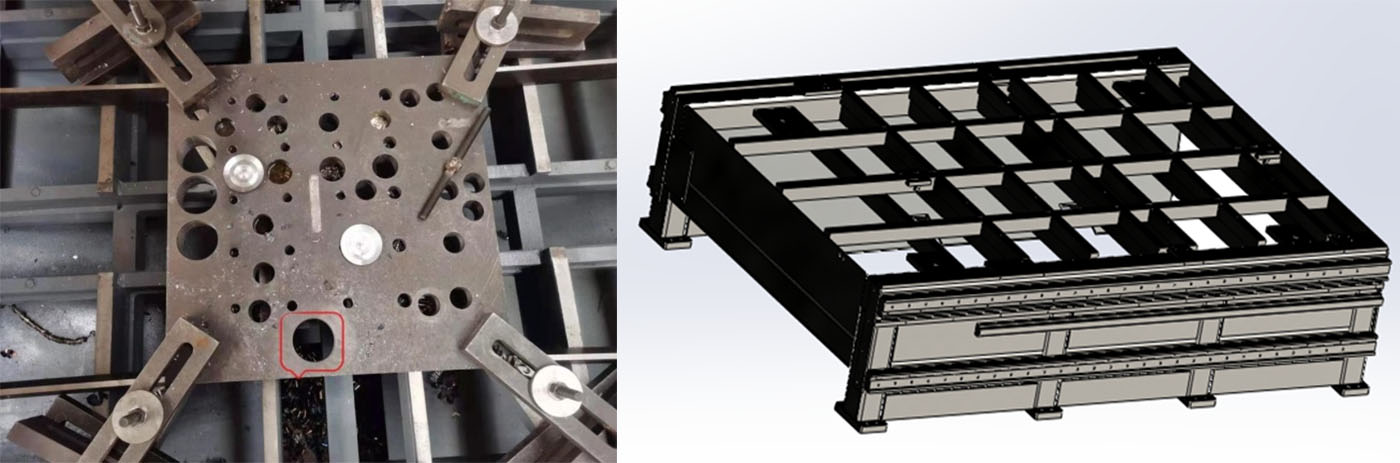

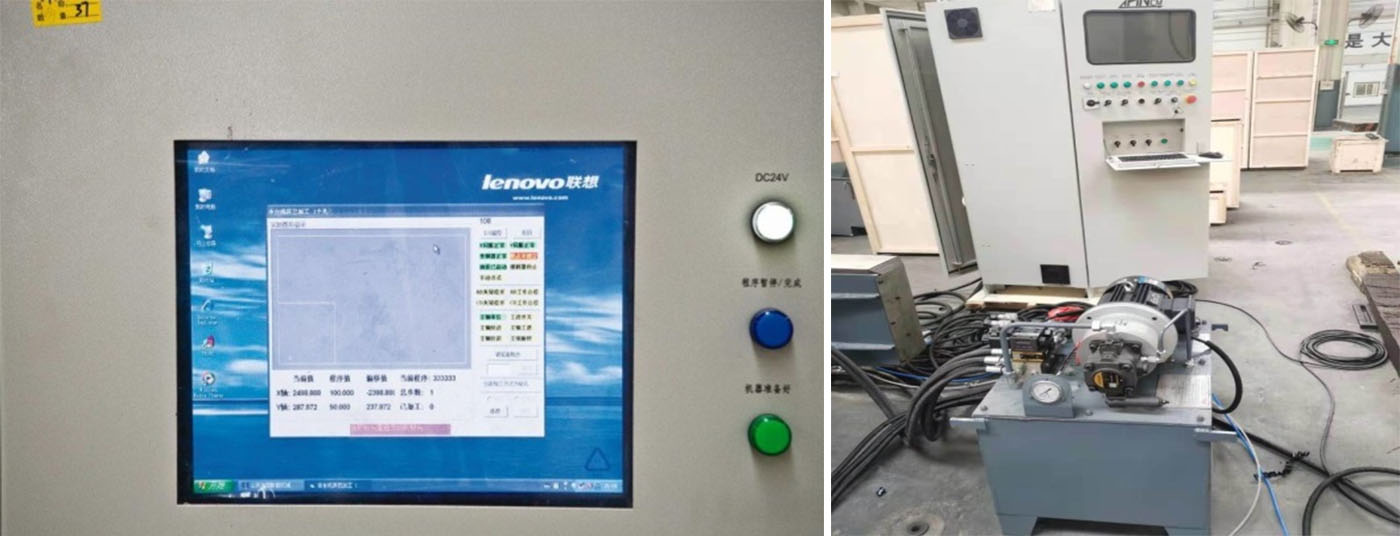

1. The machine tool mainly consists of bed, gantry, drilling power head, hydraulic system, control system, centralized lubrication system, cooling and chip removal system, etc.

2. The spindle adopts precision spindle with high rotation precision and good rigidity. Equipped with BT50 taper hole, it is convenient for tool change, which can be used to clamp twist drill and carbide drill. The spindle is driven by the spindle frequency conversion motor, which has a wide range of applications. The speed can be continuously variable in a large range to meet a variety of speed requirements. The thickness of cemented carbide drilling plate should not be about twice the diameter of drill bit.

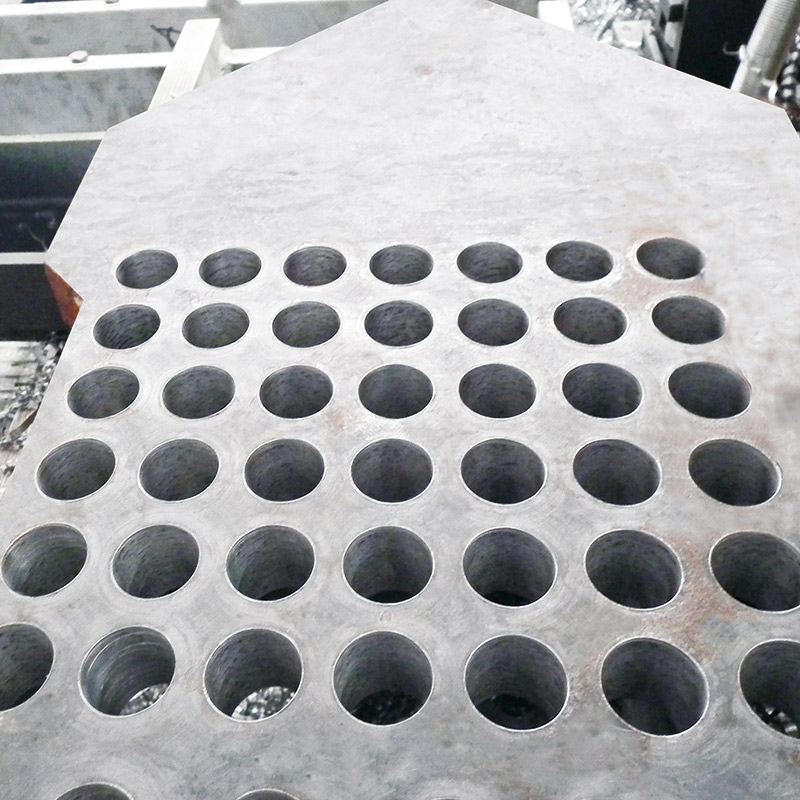

3. The machine can automatically process the starting and ending points of the working process through the upper computer software. It can not only drill through holes, but also drill blind holes, step holes and hole end chamfering. It has the advantages of high processing efficiency, high working reliability, simple structure and low maintenance cost.

4. The machine adopts centralized lubrication system instead of manual operation, and regularly pumps lubricating oil into the linear guide pair slide block and ball screw pair screw nut of each part, so as to ensure good lubrication of functional parts, improve machine performance and prolong service life.

5. The machine is equipped with a flat chain chip conveyor in the middle of the bed.

6. The cooling system has the function of internal cooling and external cooling.

Key outsourced components list

|

NO. |

Name |

Brand |

Country |

|

1 |

Linear rolling guide pair |

HIWIN/PMI/ABBA |

Taiwan, China |

|

2 |

Ball screw |

HIWIN/PMI |

Taiwan, China |

|

3 |

Solenoid valve |

ATOS/YUKEN |

Italy / Japan |

|

4 |

Servo motor |

Siemens / Mitsubishi |

Germany / Japan |

|

5 |

Servo driver |

Siemens / Mitsubishi |

Germany / Japan |

|

6 |

PLC |

Siemens / Mitsubishi |

Germany / Japan |

|

7 |

Spindle |

Kenturn |

Taiwan, China |

|

8 |

Centralized lubrication |

HERG/BIJUR |

Japan / USA |

Note: The above is our standard supplier. It’s subject to be replaced by same quality components of other brand if the above supplier can’t supply the components in case of any special matter.

Product detail pictures:

Related Product Guide:

With sophisticated technologies and facilities, strict top quality handle, reasonable value, exceptional support and close co-operation with clients, we are devoted to furnishing the ideal worth for our clients for High Quality CNC Angle Line - PHD3016&PHD4030 CNC High-speed Drilling Machine for Steel Plates – FIN CNC , The product will supply to all over the world, such as: Poland, Porto, United States, Please feel cost-free to send us your specifications and we'll respond to you asap. We've got a professional engineering team to serve for the every single detailed needs. Free samples may be sent for you personally to know far more facts. So that you can meet your desires, please really feel cost-free to contact us. You could send us emails and call us straight. Additionally, we welcome visits to our factory from all over the world for much better recognizing of our corporation. nd merchandise. In our trade with merchants of several countries, we often adhere to the principle of equality and mutual advantage. It is our hope to market, by joint efforts, both trade and friendship to our mutual benefit. We look forward to getting your inquiries.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!