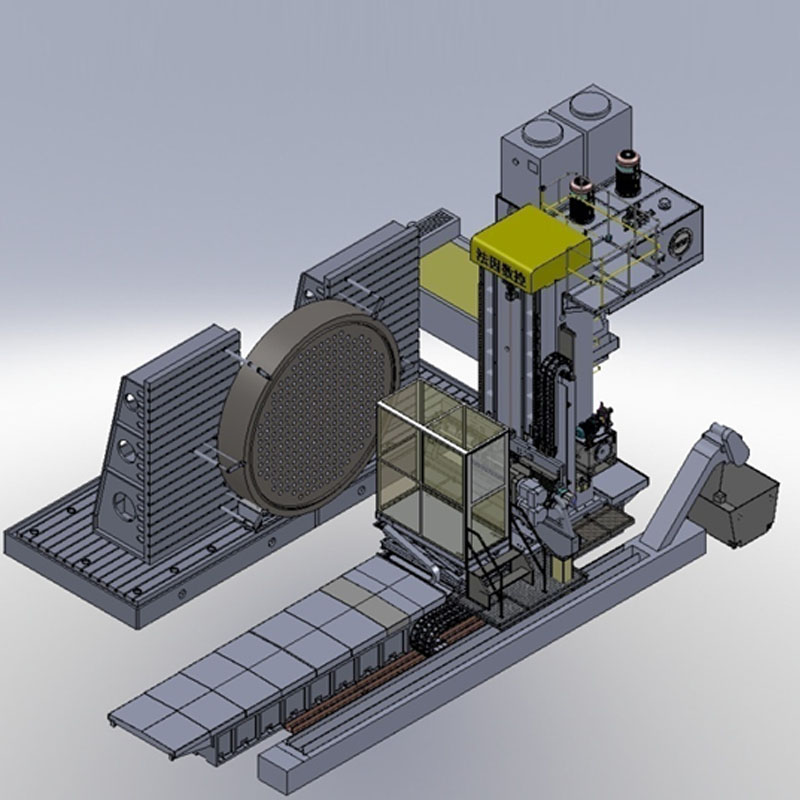

Factory wholesale Steel Punching Machine - SWZ400/9 CNC Multi Spindle Drilling Machine For Beam or U Channel steel – FIN CNC

Factory wholesale Steel Punching Machine - SWZ400/9 CNC Multi Spindle Drilling Machine For Beam or U Channel steel – FIN CNC Detail:

Product Parameter

|

NO. |

Item name |

Unit |

Parameters |

|||

|

1 |

Processing material range |

H Beam |

Web width |

mm |

100~400 |

|

|

2 |

Flange height |

mm |

75~300 |

|||

|

3 |

Channel Steel |

Web width |

mm |

126~400 |

||

|

4 |

Height |

mm |

53~104 |

|||

|

5 |

Minimum automatic feeding length |

mm |

1500 |

|||

|

6 |

Maximum feed length |

mm |

12000 |

|||

|

7 |

Maximum weight |

Kg |

1500 |

|||

|

8 |

Spindle |

Number of drilling headstocks |

3 |

|||

|

9 |

Number of spindles per drilling headstock |

3 |

||||

|

10 |

Drilling range on both sides |

mm |

¢12.5~¢30 |

|||

|

11 |

Intermediate drilling range |

mm |

¢12.5~¢40 |

|||

|

12 |

Spindle speed |

r/min |

180~560 |

|||

|

13 |

Drill clamp form |

/ |

Morse 4 |

|||

|

14 |

Axial feed rate |

mm/min |

20~300 |

|||

|

15 |

Cnc axis |

Feeding CNC axis |

Servo motor power |

Kw |

about4 |

|

|

16 |

Maximum speed |

m/min |

40 |

|||

|

17 |

Move the upper unit horizontally |

Servo motor power |

Kw |

about1.5 |

||

|

18 |

Maximum speed |

m/min |

10 |

|||

|

19 |

Fixed side, mobile side vertical movement |

Servo motor power |

Kw |

about1.5 |

||

|

20 |

Maximum speed |

m/min |

10 |

|||

|

21 |

Main machine dimensions |

mm |

about4377x1418x2772 |

|||

|

22 |

Main weight |

kg |

about4300Kg |

|||

Details and Advantages

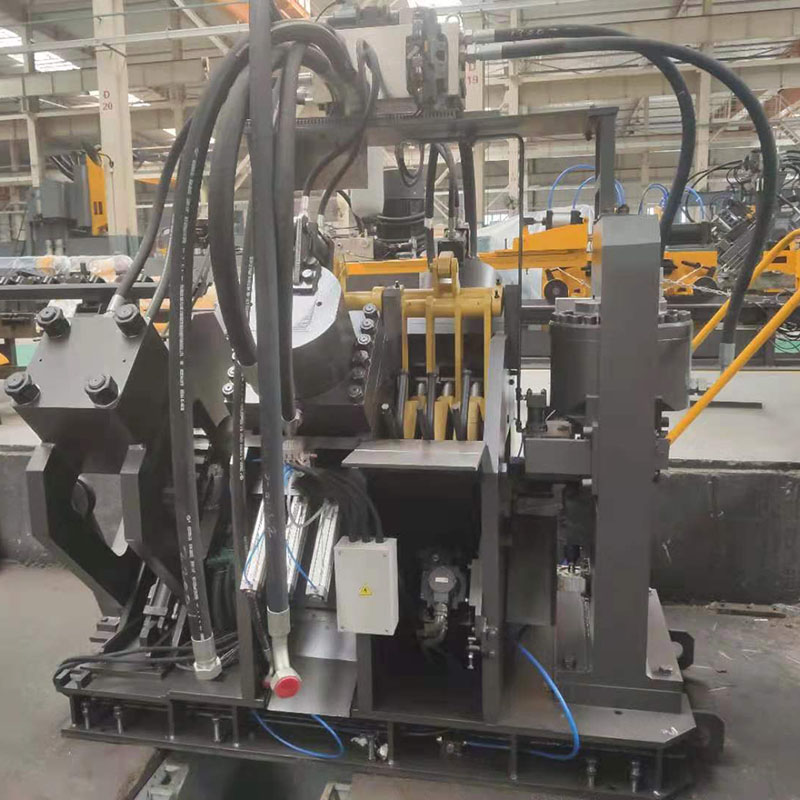

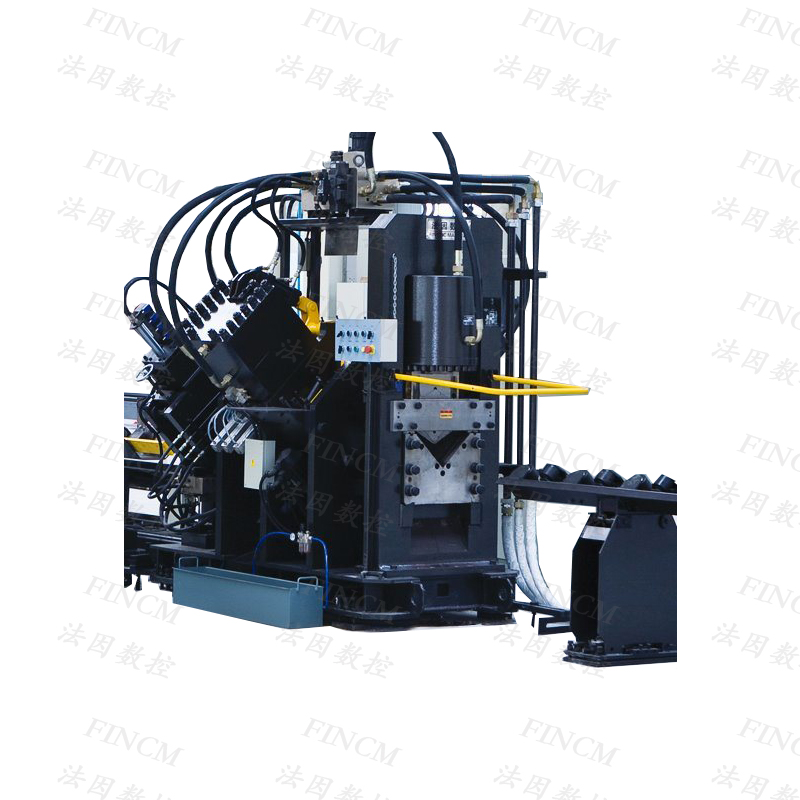

1、The machine is a frame structure welded by high-quality steel. The steel pipe is strengthened in the place by large stress. After welding, the heat aging treatment is carried out to improve the stability of the bed.

2、There are 3 CNC slides, 6 CNC axes on each slide, and 2 CNC axes on each slide. Each CNC axis is guided by precision linear rolling guide and driven by AC servo motor and ball screw. The holes on the same section of the beam can be processed at the same time, which greatly improves the positioning accuracy and efficiency of the holes in the hole group.

3、Three automatic control stroke drilling power heads are respectively installed on three CNC slide blocks for horizontal and vertical drilling. The three drilling power heads can work independently or simultaneously。

4、The spindle speed of each drilling power head is controlled by frequency converter and stepless adjusted; the feed speed is stepless adjusted by speed regulating valve, which can be adjusted rapidly in a large range according to the material of beam and diameter of drilling hole.

5、The beam is fixed by hydraulic clamping mechanism.

6、The machine is equipped with the detection device of the width of the beam and the height of the web, which can automatically compensate the machining error caused by the irregular outline of the material, and improve the machining accuracy.

7、The machine tool is equipped with an advanced cooling system, which has the advantages of less coolant consumption, cost saving and less bit wear.

Key outsourced components

|

NO. |

Item |

Brand |

Origin |

|

1 |

PLC |

INVANCE |

China |

|

2 |

Guide |

HIWIN/CSK |

Taiwan China |

|

3 |

Servo motor |

INVANCE |

China |

|

4 |

Servo drive |

INVANCE |

China |

|

5 |

Control Valve |

ATOS |

Italy |

|

6 |

Solenoid hydraulic valve |

ATOS/YUKEN |

Italy |

|

7 |

Hydraulic pump |

JUSTMARK |

Taiwan China |

Note: The above is our standard supplier. It’s subject to be replaced by same quality components of other brand if the above supplier can’t supply the components in case of any special matter.

Product detail pictures:

Related Product Guide:

"Control the quality by the details, show the strength by quality". Our company has strived to establish a highly efficient and stable staff team and explored an effective quality control process for Factory wholesale Steel Punching Machine - SWZ400/9 CNC Multi Spindle Drilling Machine For Beam or U Channel steel – FIN CNC , The product will supply to all over the world, such as: Macedonia, Riyadh, Milan, Today, We are with great passion and sincerity to further fulfill our global customers' needs with good quality and design innovation. We fully welcome customers from all over the world to establish stable and mutually beneficial business relationships, to have a bright future together.

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.