Factory Price Truck Beams – S8F Frame Double Spindle CNC Drilling Machine – FIN CNC

Factory Price Truck Beams – S8F Frame Double Spindle CNC Drilling Machine – FIN CNC Detail:

Product Parameters

| Parameter name | Unit | Parameter value | ||

| Frame process parameters | Material | Hot rolled steel 16MnL | ||

| Maximum tensile strength | MPa | 1000 | ||

| Yield Strength | MPa | 700 | ||

| Maximum drilling thickness | mm | 40(Multi-layer board) | ||

| Processing stroke | axis | mm | 1600 | |

| Y axis | mm | 1200 | ||

| Mobile side clamping | axis | mm | 500 | |

| Xaxis | mm | 500 | ||

| Drilling spindle | quantity | piece | 2 | |

| Spindle taper | BT40 | |||

| Drilling diameter range | mm | φ8~φ30 | ||

| Minimum drilling distance of dual power heads at the same time | mm | 295 | ||

| Feed stroke | mm | 450 | ||

| Rotating speed | r/min | 50~2000(Servo stepless) | ||

| Feed rate | mm /min | 0~8300(Servo stepless) | ||

| Spindle servo motor power | kW | 2×7.5 | ||

| Spindle rated torque | Nm | 150 | ||

| Spindle torque | Nm | 200 | ||

| Maximum spindle feed force | N | 7500 | ||

| Tool magazine | QTY | piece | 2 | |

| Handle form | BT40(With ordinary taper shank twist drill) | |||

| Tool magazine capacity | piece | 2×4 | ||

| CNC system | Control method | Siemens 840D SL CNC system | ||

| Number of CNC axes | piece | 7+2 | ||

| Servo motor power | Xaxis | kW | 4.3 | |

| Y axis | 2×3.1 | |||

| Z axis | 2×1.5 | |||

| Xaxis | 1.1 | |||

| Xaxis | 1.1 | |||

| Hydraulic system | System working pressure | MPa | 2~7 | |

| cooling system | Cooling method | Aerosol cooling method | ||

Details and advantages

1. The main machine mainly includes a bed, a moving gantry, a drilling power head (2) (for high-speed steel twist drill drilling), a tool change mechanism (2), a positioning, clamping and detection mechanism, and a feeding trolley (2 A), advanced cooling system, hydraulic system, CNC system, protective cover and other parts.

2. The machine adopts the form of fixed bed and movable gantry.

3. The horizontal Y axis and vertical Z axis of the two drilling power heads move independently. The Y axis movement of each power head is driven by a separate screw pair, which can cross the center line of the material; each CNC axis is guided by a linear rolling guide. AC servo motor + ball screw drive. The power head has an anti-collision design to prevent the power head from colliding during automatic operation.

4. The drilling power head adopts imported precision spindle for machining center; equipped with BT40 taper hole, it is convenient to change the tool and can be clamped various drills; the spindle is driven by servo spindle motor, which can meet the requirements of various speeds and tool changing functions.

5. In order to meet the processing of different apertures, the machine is equipped with in-line tool magazines (2), and two power heads can realize automatic tool change.

6. The machine has an independent automatic detection device, which can automatically detect the width of the material and feed it back to the CNC system.

7. Each side of the machine bed is equipped with a set of laser alignment for rough positioning of the frame.

9. The machine is equipped with a hydraulic system, which is mainly used for material positioning and clamping.

10. The machine is equipped with an aerosol cooling system for drilling and cooling of material.

11. The machine gantry beam is equipped with an organ type protective cover, and the bed rail is equipped with a telescopic steel plate type protective cover.

12. The machine adopts Siemens 840D SL numerical control system, which can realize CAD automatic programming and has the function of layer recognition. The system can automatically determine the working distance according to the tool length (manual input) and the height of the frame, generally 5mm, and its value can be set according to requirements.

13. The machine is equipped with a linear bar code (one-dimensional bar code, CODE-128 coding standard) scanning system, which automatically calls the processing program by scanning the linear bar code of the frame with a handheld wireless scanner.

14. The machine has the counting function of automatically accumulating the number of drilling holes and the number of processed material, and cannot be cleared; in addition, it has a production counting function, which can record the number of material processed by each processing program, and can be queried and cleared.

Key outsourced components list

|

NO. |

Item |

brand |

Origin |

|

1 |

Linear Guides |

HIWIN/PMI |

Taiwan, China |

|

2 |

Precision spindle |

Kenturn |

Taiwan, China |

|

3 |

Linear barcode scanning system |

SYMBOL |

America |

|

4 |

CNC system |

Siemens 840D SL |

Germany |

|

5 |

Servo motor |

Siemens |

Germany |

|

6 |

Spindle servo motor |

Siemens |

Germany |

|

7 |

Main hydraulic parts |

ATOS |

Italy |

|

8 |

Drag chain |

Misumi |

Germany |

|

9 |

Low-voltage electrical components |

Schneider |

France |

|

10 |

Power |

Siemens |

Germany |

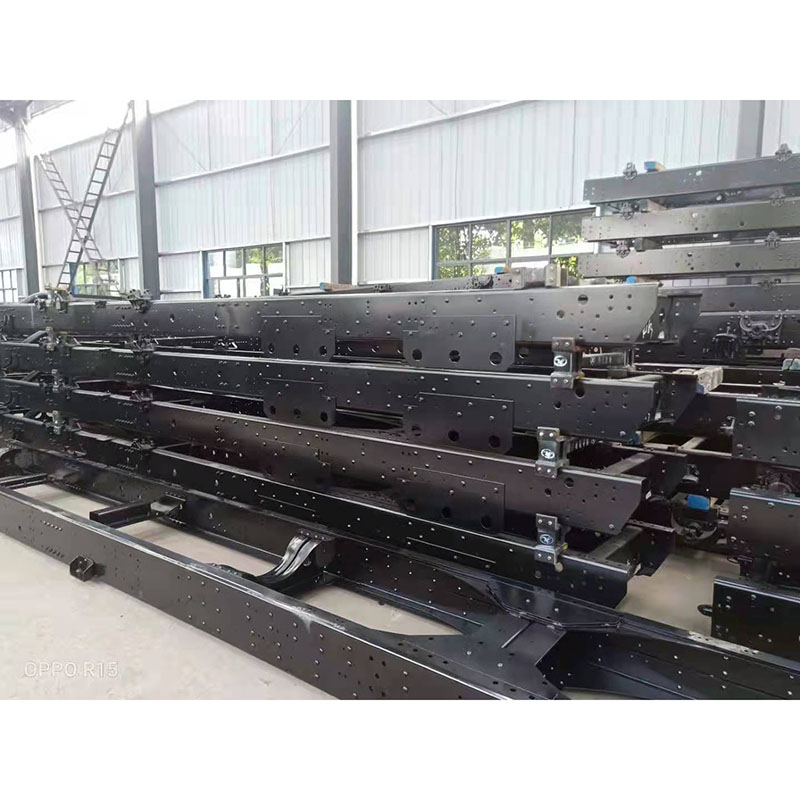

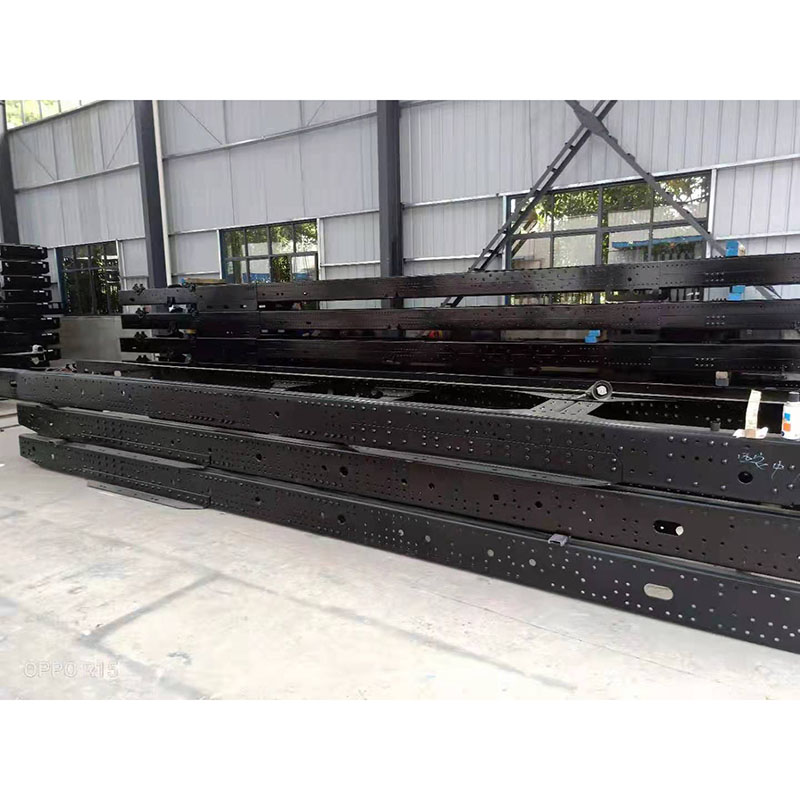

Product detail pictures:

Related Product Guide:

We offer great strength in quality and development,merchandising,sales and marketing and operation for Factory Price Truck Beams – S8F Frame Double Spindle CNC Drilling Machine – FIN CNC , The product will supply to all over the world, such as: Suriname, Japan, Auckland, We're introduced as a one of the growing manufacture supplier and export of our merchandise. Now we have a team of dedicated trained experienced who take care the quality and timely supply. If you are looking for Good Quality at a good price and timely delivery. Do contact us.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.