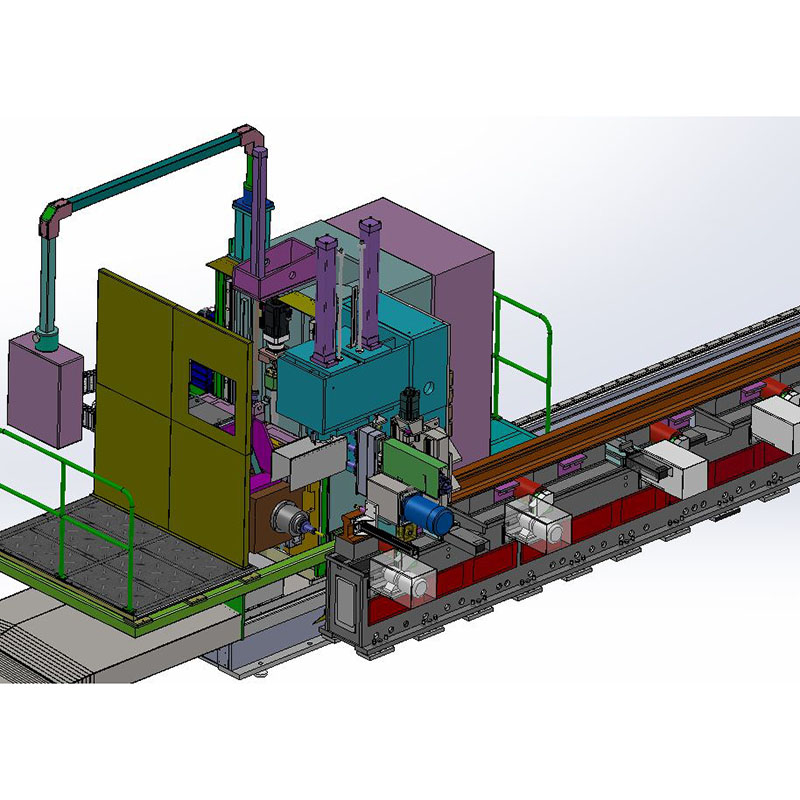

Factory Price Truck Beams – RDL25B-2 CNC Rail Drilling Machine – FIN CNC

Factory Price Truck Beams – RDL25B-2 CNC Rail Drilling Machine – FIN CNC Detail:

Product Parameters

| Rail size range | Bottom width | 40~180mm |

| Rail height | 93~192mm | |

| Abdominal thickness | 12~44mm | |

| Rail length (after sawing) | 6~25m | |

| Material quality | U71Mn σb≥90Kg/mm² HB380~420

PD3 σb≥98Kg/mm² HB380~420 |

|

| Feeding device | Number of feeding racks | 10 |

| Number of rails that can be placed | 12 | |

| Maximum speed of lateral movement | 8 m / min | |

| Blanking device | Number of blanking racks | 9 |

| Number of rails that can be placed | 12 | |

| Maximum speed of lateral movement | 8 m / min | |

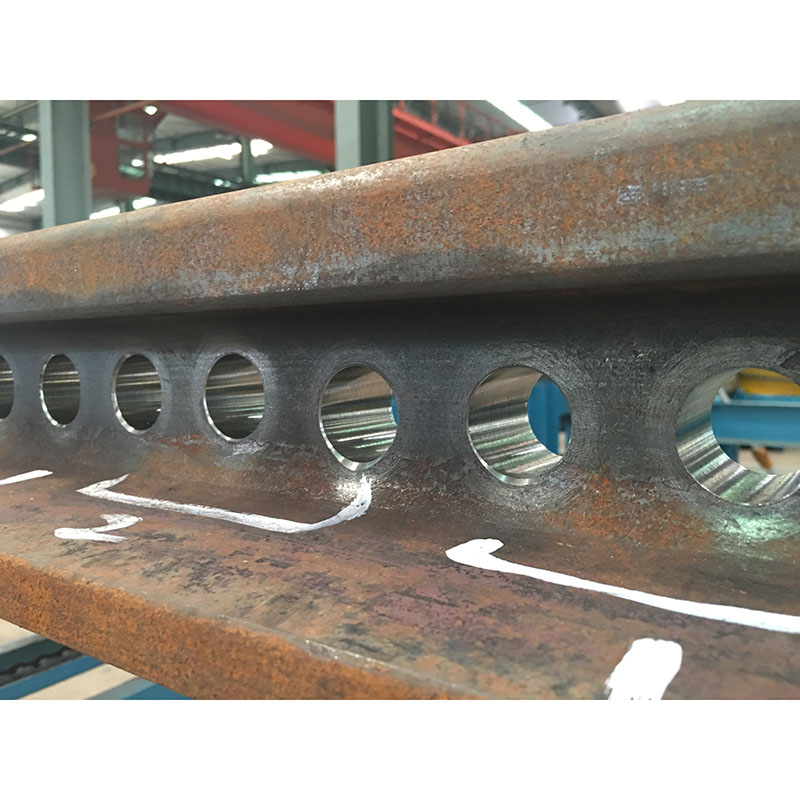

| Bit | Diameter range | φ 9.8~φ 37 (carbide bit) |

| Length range | 3D~4D | |

| Diameter range | >φ 37~φ 65 (ordinary high speed steel bit) | |

| Processing requirements | Range of hole height | 35~100mm |

| Number of holes on each rail | 1-4 type | |

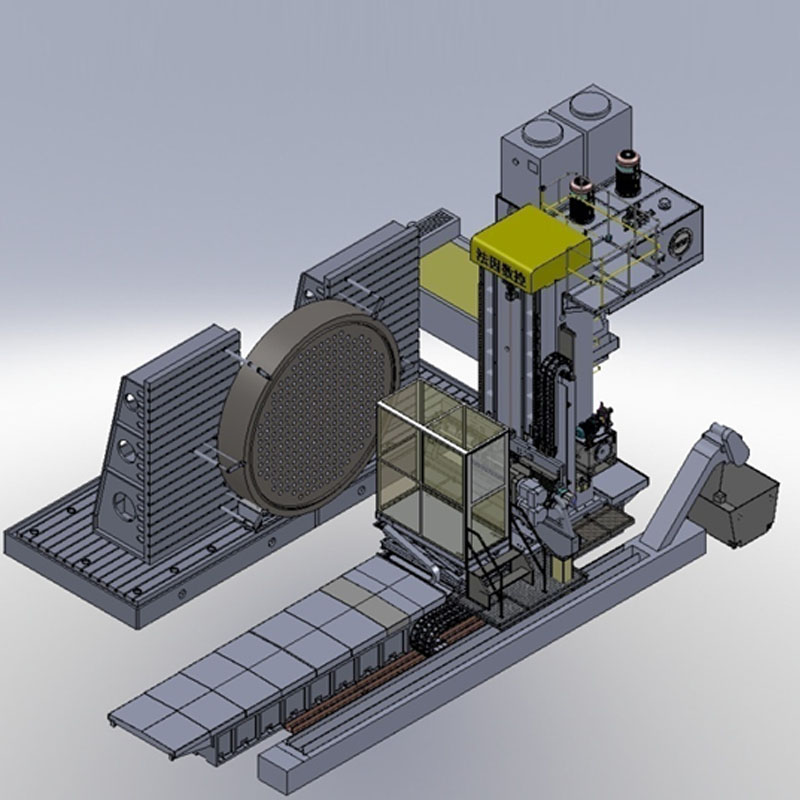

| Mobile column (including drill pin power box) | number | 2 |

| Spindle taper hole | BT50 | |

| Spindle speed range (stepless speed regulation) | 10~3000r/min | |

| Spindle servo motor power | 2×37kW | |

| Maximum output torque of spindle | 470Nm | |

| Vertical slide stroke (Y-axis) | ≥800mm | |

| Horizontal drilling feed stroke (Z-axis) | ≥ 500mm | |

| Effective machining stroke of horizontal movement of single column (x-axis) | ≥25m | |

| 10. Maximum moving speed of Y and Z axes | 12m / min (servo speed regulation) |

|

| Suction cup size (L) × wide × (high) | 250×200×120mm (the length of suction cup at both ends is 500mm, and replaceable magnetic pad is placed for clamping in rolling section) |

|

| Working suction | ≥250N/cm² | |

| Cylinder bore × trip | ≥Φ50×250mm | |

| Single cylinder thrust | ≥700Kg | |

| Conveying speed | ≤15m/min | |

| Pressing force | ≥1500Kg/set | |

| The thickness is 20 mm. It can be used with electric permanent magnet sucker and can be replaced | ||

| Tool magazine | Quantity | 2 sets (one set for each column) |

| Capacity | 4 | |

| Chip removal and cooling | Chip conveyor type | Flat chain |

| Electrical system (2 sets) | CNC system | Siemens 828D 2 sets |

| Number of CNC axes | 8+2 | |

| Tool cooling mode | Internal cooling, MQL micro oil mist cooling | |

| Overall dimension (L) × Wide×(high) | About 65m×9m×3.5m |

Details and advantages

1. The precision linear rolling guide and high precision inclined rack on the machine bed are arranged horizontally. The rack is installed between the two guide rails, and the mobile column is installed on the machine bed.

2. There are 8 CNC axes and 2 servo spindles in the machine tool. Each CNC axis is guided by precision linear rolling guide. The x-axis is driven by AC servo motor through precision ball screw. Double nut pre-tightening structure is used in the ball screw, which can eliminate the axial back clearance and reduce the elastic displacement caused by the axial force. There is no clearance in the movement, and the host machine has a separate magnetic grid ruler detection system in the X and Y axis movement of the bed, which can ensure the positioning accuracy of coordinate movement;

3. The machine has the function of laser end Searching and locating the origin, which is convenient for tool processing and improving the processing efficiency. The repeatability of laser alignment device is less than 0.2mm. It also has the function of rail length detection, which can detect both ends of the rail through the laser switch, so as to detect the length of the rail. It can recheck the incoming materials and reduce errors.

4. The drilling tool is a molding tool. The drilling and front chamfering are completed at one time. The tool is made of Transposition carbide blade, and the spindle is cooled by air mist. There is a chamfering head on the reverse side for chamfering, and the chamfering tool is also of carbide blade type structure. This chamfering tool has a large chamfering range and does not need to change the tool during processing.

5. Siemens 828d CNC system is used in the CNC system, which can monitor the drilling process in real time. It can recognize the two-dimensional code and call the machining program.

Key outsourced components list

|

NO. |

Name |

Brand |

Country |

|

1 |

CNC system |

Siemens |

Germany |

|

2 |

Servo motor and drive |

Siemens |

Germany |

|

3 |

Spindle servo motor and drive |

Siemens |

Germany |

|

4 |

Precision spindle |

KENTURN |

Taiwan, China |

|

5 |

Ball screw pair |

NEFF |

Germany |

|

6 |

Linear guide pair |

HIWIN/PMI |

Taiwan, China |

|

7 |

Drag chain |

IGUS/JIAJI |

Germany / China |

|

8 |

Magnetic ruler |

SIKO |

Germany |

|

9 |

Precision reducer |

APEX |

Taiwan, China |

|

10 |

Precision gear rack pair |

APEX |

Taiwan, China |

|

11 |

Hydraulic valve |

ATOS |

Italy |

|

12 |

Oil pump |

JUSTMARK |

Taiwan, China |

|

13 |

Low voltage electrical components |

Schneider |

France |

|

14 |

Laser alignment device |

SICK |

Germany |

Note: The above is our standard supplier. It’s subject to be replaced by same quality components of other brand if the above supplier can’t supply the components in case of any special matter.

Product detail pictures:

Related Product Guide:

With advanced technologies and facilities, strict high quality regulate, reasonable price tag, excellent support and close co-operation with shoppers, we have been devoted to furnishing the best benefit for our buyers for Factory Price Truck Beams – RDL25B-2 CNC Rail Drilling Machine – FIN CNC , The product will supply to all over the world, such as: Singapore, Austria, Thailand, We've got sufficient experience in producing products according to samples or drawings. We warmly welcome customers from home and abroad to visit our company, and to cooperate with us for a splendid future together.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!