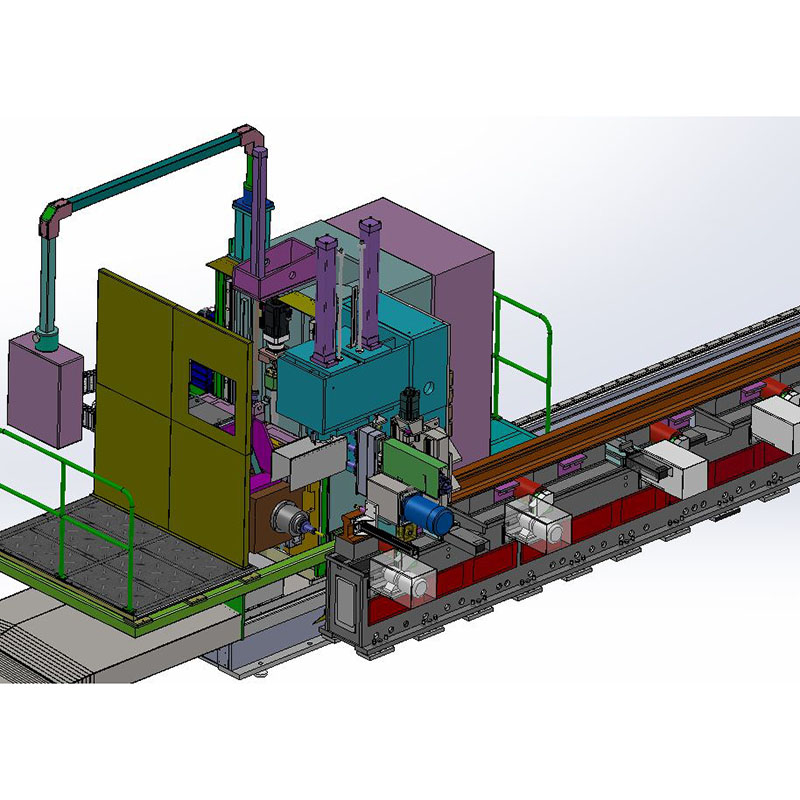

Factory Price Truck Beams – RD90A Rail Frog CNC Drilling Machine – FIN CNC

Factory Price Truck Beams – RD90A Rail Frog CNC Drilling Machine – FIN CNC Detail:

Product Parameters

| Parameter name | Item | Parameter value |

| Working table | Length*width | 10000×1000mm |

| T-slot width | 28mm | |

| Spacing and number of longitudinal T-slots | 140mm, 7piece | |

| Spacing and number of transverse T-slot | 600mm, 17piece | |

| Drilling spindle | Number | 2 |

| Spindle taper | BT50 | |

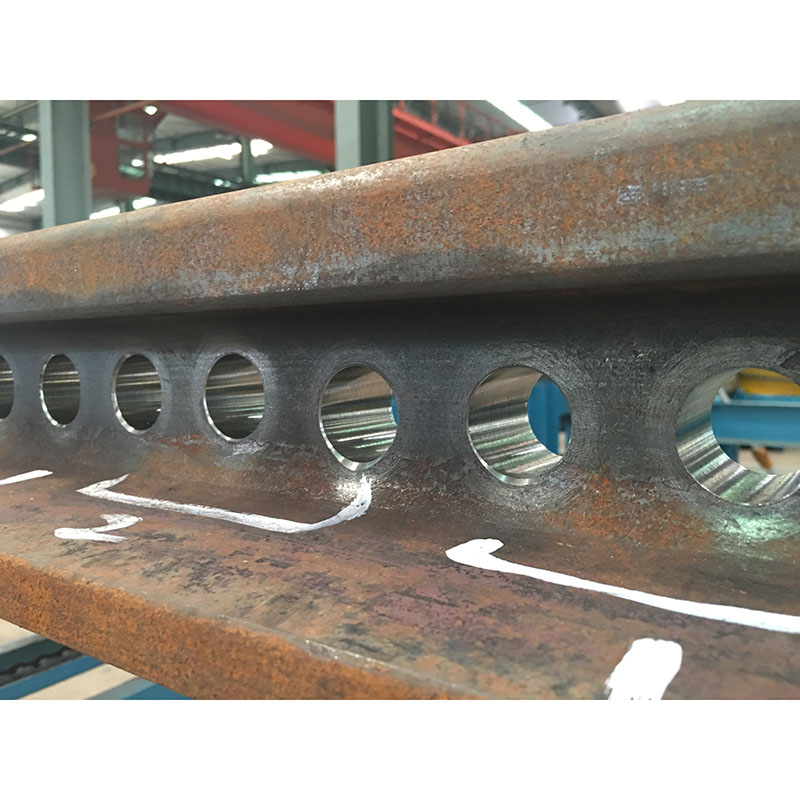

| Maximum drilling diameter | Φ50mm | |

| Maximum drilling depth | 160mm | |

| Spindle speed (frequency conversion stepless) | 50~2500r/min | |

| Maximum torque of spindle (n≤600r/min) | 288/350 N*m | |

| Spindle motor power | 2×18.5kW | |

| Minimum distance from spindle center line to work surface | 150mm | |

| Rotary movement of the turntable (W axis) | Rotation angle | ±15° |

| Motor Power | 2×1.5kW | |

| Compressed air | Pressure | ≥0.5 Mpa |

| Flow | ≥0.2 m3/min | |

| Cooling system | Coolant cooling | 1set |

| Cooling method | Internal cooling | |

| Maximum coolant pressure | 2 MPa | |

| Chip removal device | Chain plate chip conveyor | 2 sets |

| Hydraulic system | System pressure | 6 MPa |

| Hydraulic pump motor power | 2.2 kW | |

| Electrical System | CNC system | Siemens828D |

| QTY | 2set | |

| Number of CNC axis | 2×5piece | |

| Positioning accuracy | X axis | 0.15mm/total length |

| Y axis | 0.05mm/ total length | |

| Z axis | 0.05mm/ total length |

Details and advantages

1. Worktable

A special backing plate and fixture are placed on the worktable of this machine, and the rail to be processed is placed on the special backing plate whose height has been adjusted, and then the rail is pressed tightly with a pressure plate through a T-slot.

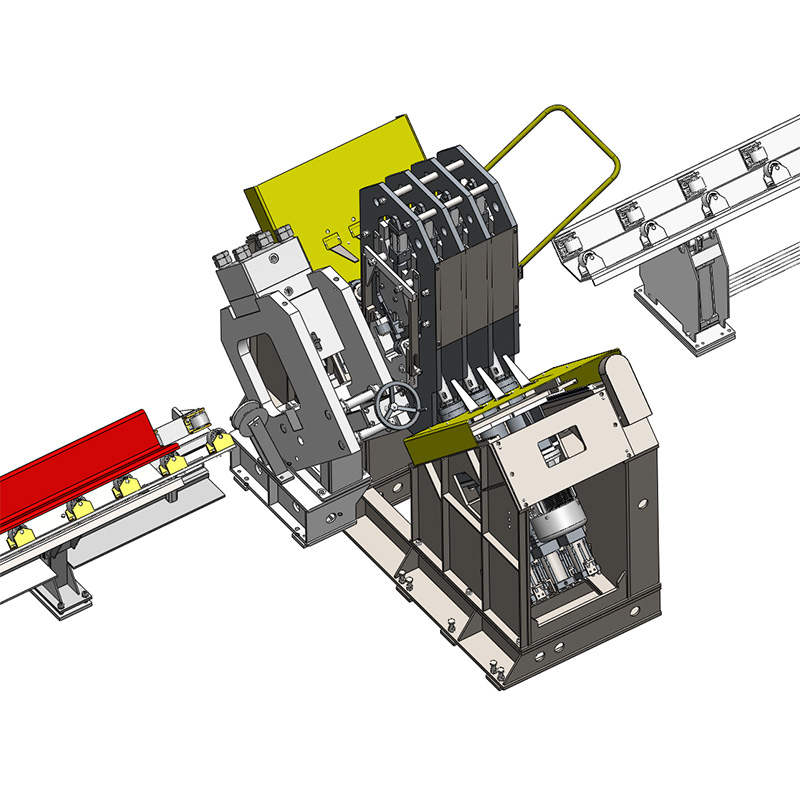

2. Bed

Between the two precision linear rolling guide pairs on the bed, a high-precision helical rack is installed and a clamping bar used by the locking mechanism is arranged. The X-axis slide plate is driven by a servo motor, precision reducer, gear, and rack. A hydraulic locking cylinder is installed on the X-axis slide plate to ensure the stability of processing.

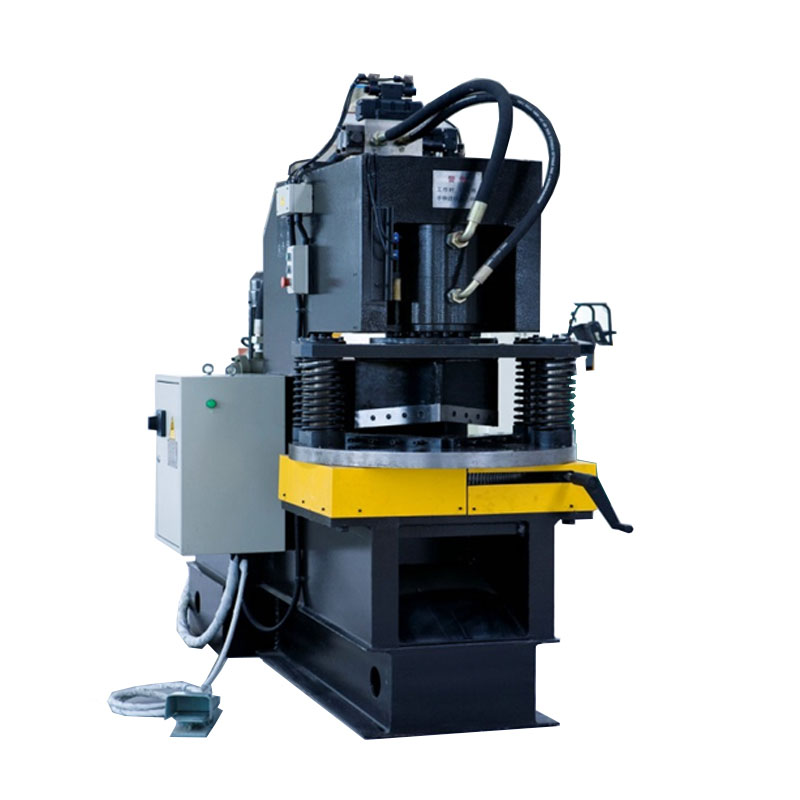

3. Turntable

The lifting table is equipped with a turntable with a rotatable angle, and the turning center of the turntable is equipped with a high-load tapered roller bearing, which is flexible and reliable in rotation. A protective cover is installed on both sides of the turntable, and a PVC soft board is installed on the outside of the protective cover, and a brush is installed at the contact point of the front end and the upper surface of the lifting platform to block iron filings.

4. Drilling power head

A drilling power head is installed on the Z-axis slide plate above the turntable. The drilling head uses a spindle frequency conversion motor to drive the spindle through a synchronous belt deceleration. The drilling power head spindle uses Taiwan’s internal cooling precision spindle. Shaped spring automatic broaching mechanism, hydraulic cylinder to loosen the drilling head, it is very convenient to replace the tool handle. The spindle motor and the end of the spindle are protected by a protective cover to prevent the coolant from splashing.

5. Chip removal and cooling

A chain plate type chip conveyor is arranged between the workbench and the bed on both sides. The iron chips and coolant generated during processing can be discharged into the chip box through the chip conveyor for easy cleaning. The cooling liquid flows back to the water tank at the bottom of the chip conveyor (below the chain plate). A filter device is arranged on the water tank, and the cooling liquid is recycled after being filtered.

6. Automatic lubrication system

This machine is equipped with an automatic lubrication device, which can automatically lubricate all linear rolling guide pairs, ball screw pairs, rack and pinion pairs and other motion pairs to ensure the service life and machining accuracy of the machine.

7. Hydraulic system

The hydraulic system mainly provides power source for X-axis locking, W-axis (rotating axis) locking, and punching cylinder.

8. Electrical system

This machine is composed of two sets of Siemens 828D CNC system and Siemens servo system, etc., which are distributed on both sides of the workbench. Each set can work independently, and each set of systems has channels to control the opposite system and perform processing. program.

Siemens 828D CNC system has high openness and flexibility, strong system stability and reliability.

The system can carry out the secondary development of the user interface, can develop the relevant processing parameter interface for specific customers, and display in Chinese, and the operation is simple and intuitive.

Key outsourced components list

|

NO. |

Item |

Brand |

Origin |

|

1 |

Linear guide pair |

HIWIN/YINTAI |

Taiwan, China |

|

2 |

CNC system |

Siemens |

Germany |

|

3 |

servo motor |

Siemens |

Germany |

|

4 |

Hydraulic valve |

Justmark or ATOS |

Taiwan, China /Italy |

|

5 |

Oil pump |

Justmark |

Taiwan, China |

|

6 |

Gears, racks and reducers |

ATLANTA |

Germany |

|

7 |

Precision spindle |

KENTURN |

Taiwan, China |

|

8 |

Centralized Lubrication System |

HERG |

Japan |

Note: The above is our standard supplier. It’s subject to be replaced by same quality components of other brand if the above supplier can’t supply the components in case of any special matter.

Product detail pictures:

Related Product Guide:

We not only will try our greatest to offer you excellent services to each individual client, but also are ready to receive any suggestion offered by our buyers for Factory Price Truck Beams – RD90A Rail Frog CNC Drilling Machine – FIN CNC , The product will supply to all over the world, such as: Sevilla, Slovenia, Portugal, For anyone who is keen on any of our goods right after you view our product list, please really feel absolutely free to get in touch with us for inquiries. You are able to send us emails and contact us for consultation and we shall respond to you as soon as we can. If it's easy, you may locate out our address in our web-site and come to our business for far more information of our products by your self. We are always ready to construct extended and steady co-operation relations with any possible customers in the related fields.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.