Factory Price Truck Beams – PUL14 CNC U Channel and Flat Bar Punching Shearing Marking Machine – FIN CNC

Factory Price Truck Beams – PUL14 CNC U Channel and Flat Bar Punching Shearing Marking Machine – FIN CNC Detail:

Product Parameters

| Working material range | 80x43x5~140x60x8mm(U Channel) |

| 40×3-80x8mm(Flat bar) | |

| Material type | Q235 |

| Punching nominal force | 950KN |

| Maximum punching diameter | φ26mm(Round hole) |

| φ22x60mm(Oval hole) | |

| Number of punching positions | 3 |

| Marking nominal force | 630 KN |

| Number of marking groups | 4 |

| Number of marking per group | 10 |

| Character size | 14x10x19mm |

| Nominal shear force | 750KN(strip steel) |

| 1000KN(Channel -steel) | |

| Cut off mode | Single blade shearing |

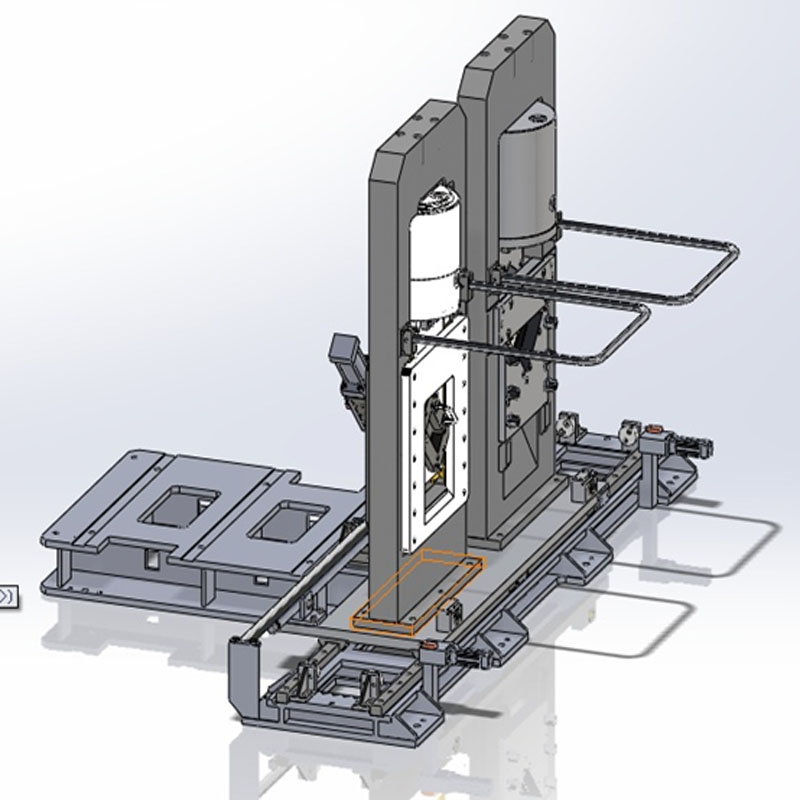

| Maximum raw material length | 9m |

| Maximum finished material length | 3m |

| Machining accuracy | Meet the requirements of GB / T 2694-2010 |

| Cooling mode | water cooling |

| Total power of equipment | 33KW |

| Machine dimensions | 27x9x2.2m |

| Net weight | About 14tons |

Details and advantages

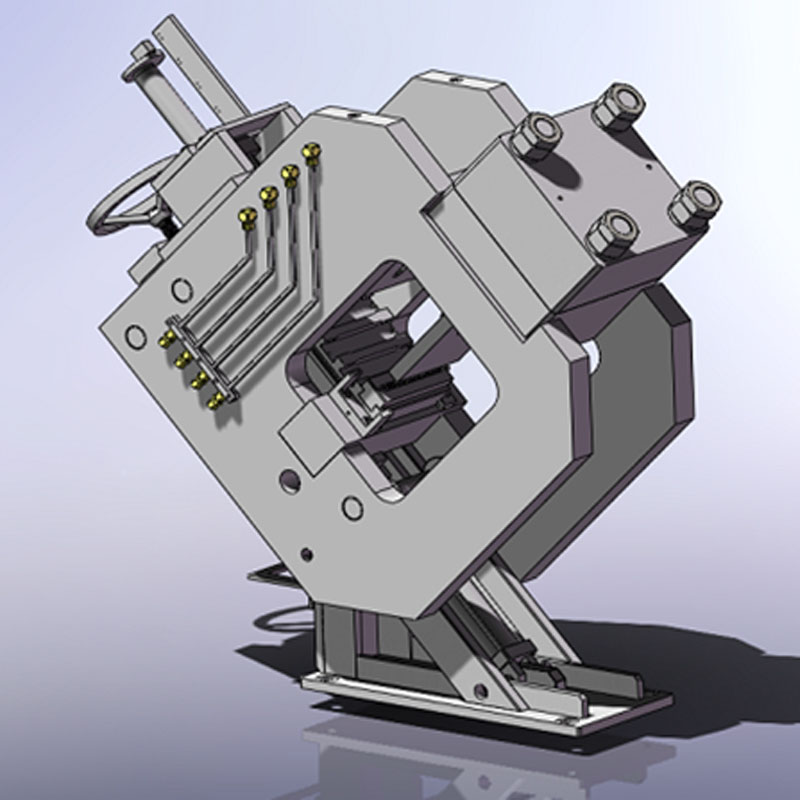

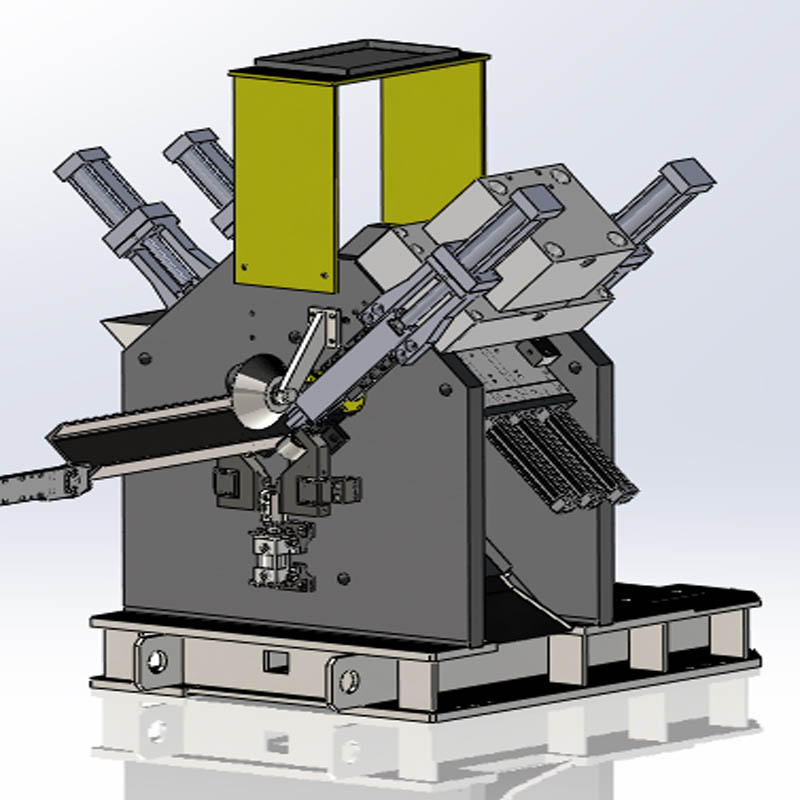

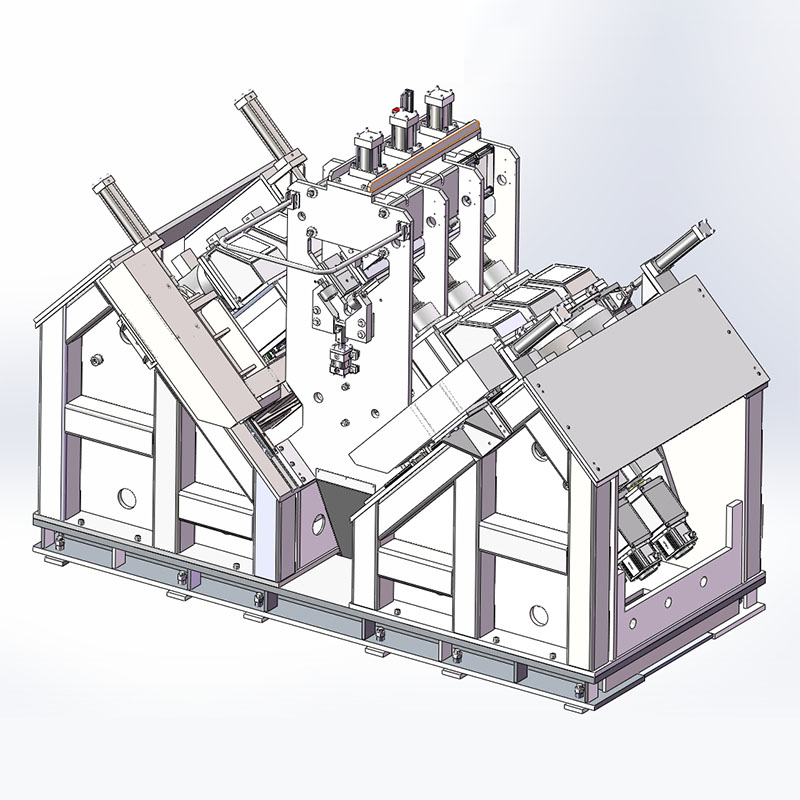

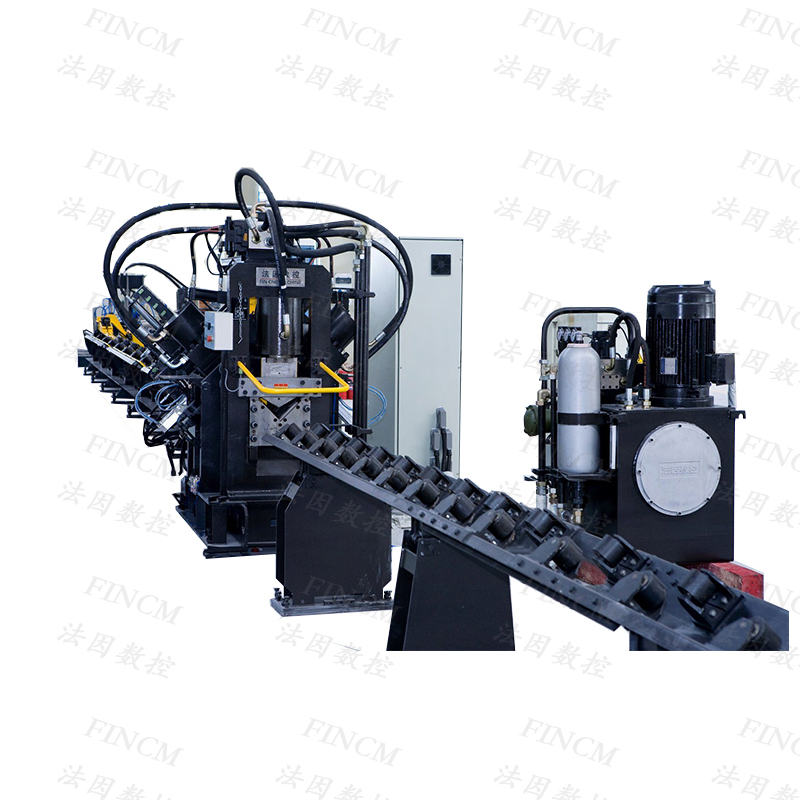

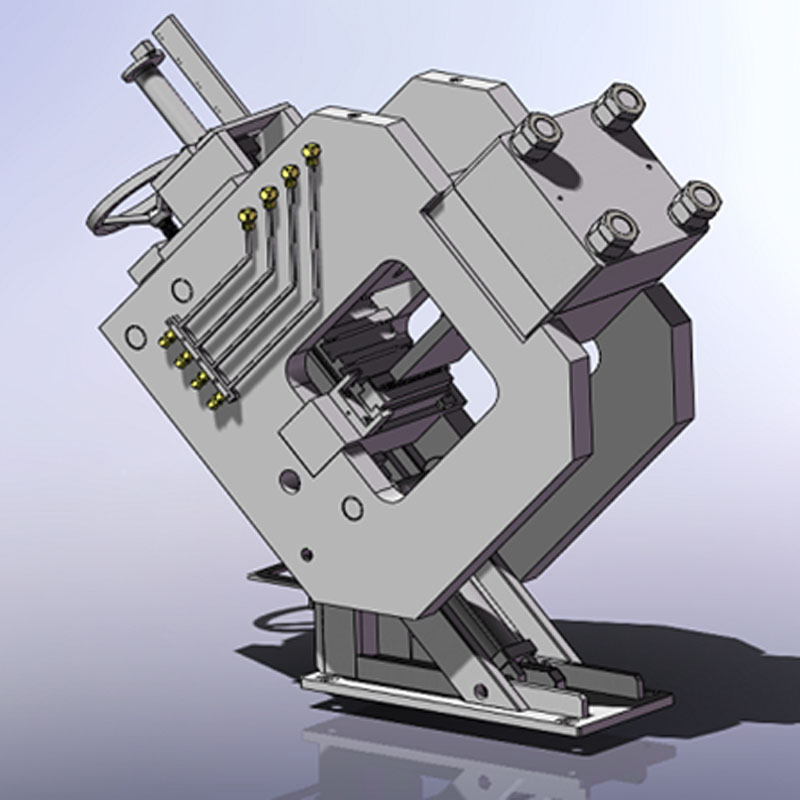

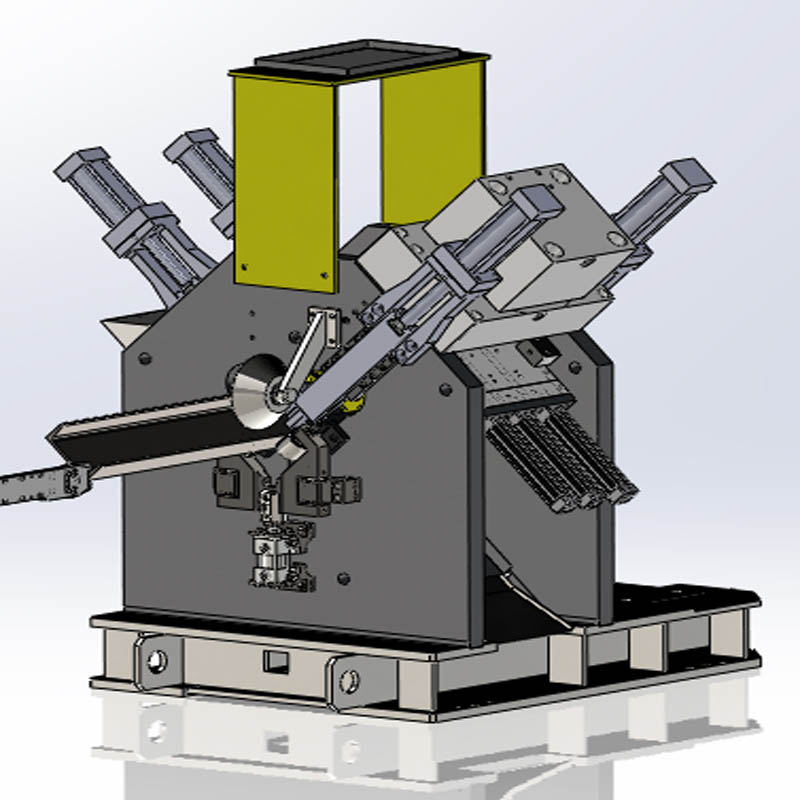

1. The main machine consists of marking unit, punching unit and shearing unit

① The marking unit adopts a closed body. With four interchangeable characters cassette, each cassette can accommodate 10 characters; Channel steel material can only be marked on the web.

② The punching unit adopts a closed body, which can punch three holes with different diameters (round hole and oval hole) on the material.

③ The shearing unit consists of two shearing device: flat bar shearing and channel shearing. Single blade cutting mechanism is adopted to ensure neat cutting section, convenient adjustment of cutting gap and material saving.

2. The material is clamped by pneumatic clamp and moves quickly for positioning. The material is driven by servo motor and driven by gear rack, with high positioning accuracy.

3. The cross transverse conveyor is composed of four chains with shifting blocks and frame body, and the chain is driven by motor through reducer.

4. The output conveyor is composed of conveyor and cylinder. After the finished material comes out of the main machine part, it is rotated and sent out of the production line.

5. The machine has three CNC axes: the movement and positioning of the feeding trolley and the up & down movement and positioning of the punching tools.

6. The computer programming is easy, and can display the material graphics and the coordinate size of the hole position, which is convenient for inspection. The upper computer management is adopted, which greatly facilitates the storage and call of the program; Graphic display; Fault diagnosis and remote communication.

7. Cooling mode of hydraulic power pack: water cooling or air cooling (optional).

Key outsourced components list

| NO | Name | Brand | Country |

| 1 | AC servo motor | Delta/Schneider | Taiwan, China / France |

| 2 | PLC | Yokogawa/ Schneider | Japan / France |

| 3 | Input module | Yokogawa/ Schneider | Japan / France |

| 4 | output module | Yokogawa/ Schneider | Japan / France |

| 5 | Positioning module | Yokogawa/ Schneider | Japan / France |

| 6 | Contactor | Siemens | Germany |

| 7 | Motor switch | Siemens | Germany |

| 8 | Supporting chain | Kabel | Germany |

| 9 | Electromagnetic unloading valve | ATOS | Italy |

| 10 | Relief valve | ATOS | Italy |

| 11 | Electro hydraulic directional valve | JUSTMARK | Taiwan, China |

| 12 | Drag Plate | AirTAC | Taiwan, China |

| 13 | Air valve | AirTAC | Taiwan, China |

| 14 | Cylinder | SMC | Japan |

| 15 | Duplex | SMC | Japan |

Note: The above is our standard supplier. It’s subject to be replaced by same quality components of other brand if the above supplier can’t supply the components in case of any special matter.

Product detail pictures:

Related Product Guide:

"Quality 1st, Honesty as base, Sincere company and mutual profit" is our idea, in an effort to create consistently and pursue the excellence for Factory Price Truck Beams – PUL14 CNC U Channel and Flat Bar Punching Shearing Marking Machine – FIN CNC , The product will supply to all over the world, such as: Philippines, Slovenia, Slovak Republic, Our company is working by the operation principle of "integrity-based, cooperation created, people oriented, win-win cooperation". We hope we can have a friendly relationship with businessman from all over the world

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!