Factory Price Truck Beams – PPL1255 CNC Punching Machine for Plates Used for Truck Chassis Beams – FIN CNC

Factory Price Truck Beams – PPL1255 CNC Punching Machine for Plates Used for Truck Chassis Beams – FIN CNC Detail:

Product Parameters

| NO. | Item | Parameter | ||

| PP1213A | PP1009S | |||

| 1 | Punching Force | 1200KN | 1000KN | |

| 2 | Maximum plate size | 800×3500 800×7000mm(Secondary positioning) |

||

| 3 | Plate thickness range | 4~12mm | 4~12mm | |

| 4 | Punch Station | Module number | 13mm | 9mm(top 5, bottom 4) |

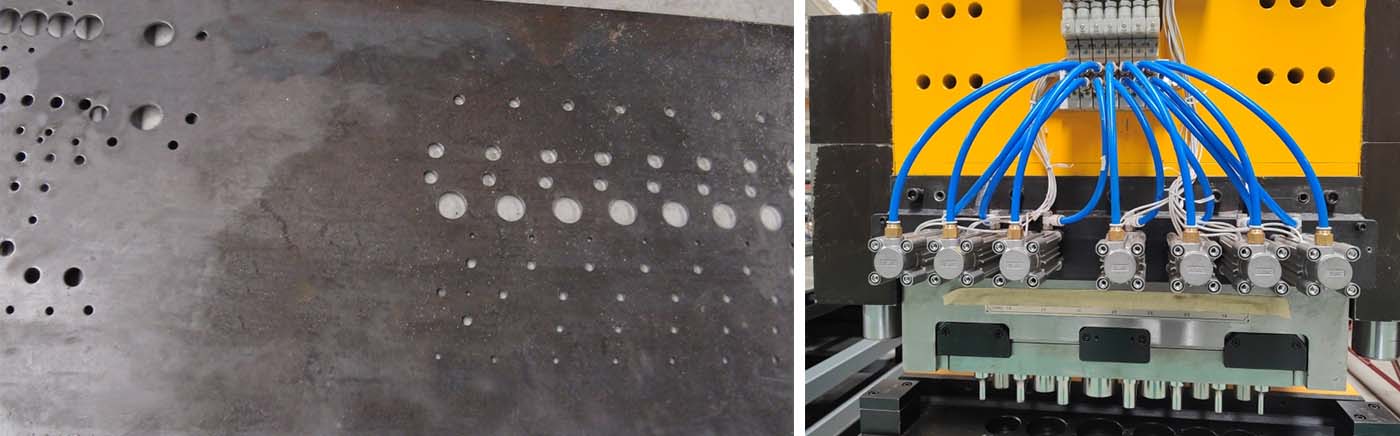

| Maximum punch diameter | φ60 | φ50 | ||

| 5 | Punch size(mm) | φ9, φ11, φ13, φ15, φ17, φ21, φ22, φ30, φ34, φ36, φ45, φ50, φ60 (A set of die with plate thickness of 8mm) |

φ9, φ11, φ13, φ15, φ17, φ21, φ25, φ30, φ35 (including a set of die with plate thickness of 8mm) | |

| 6 | Number of punches per minute | 〉42 | <42 | |

| 7 | Warpage extent | <2mm | <25 | |

| 8 | Number of clamps | 3 | ||

| 9 | System pressure | High pressure | 24MPa | |

| Low pressure | 6MPa | |||

| 10 | Air pressure | 0.5MPa | ||

| 11 | Motor power of hydraulic pump | 22kW | ||

| 12 | X-axis servo motor power | 5kW | ||

| 13 | Y-axis servo motor power | 5kW | ||

| 14 | Total capacity | 55 kVA | ||

Details and advantages

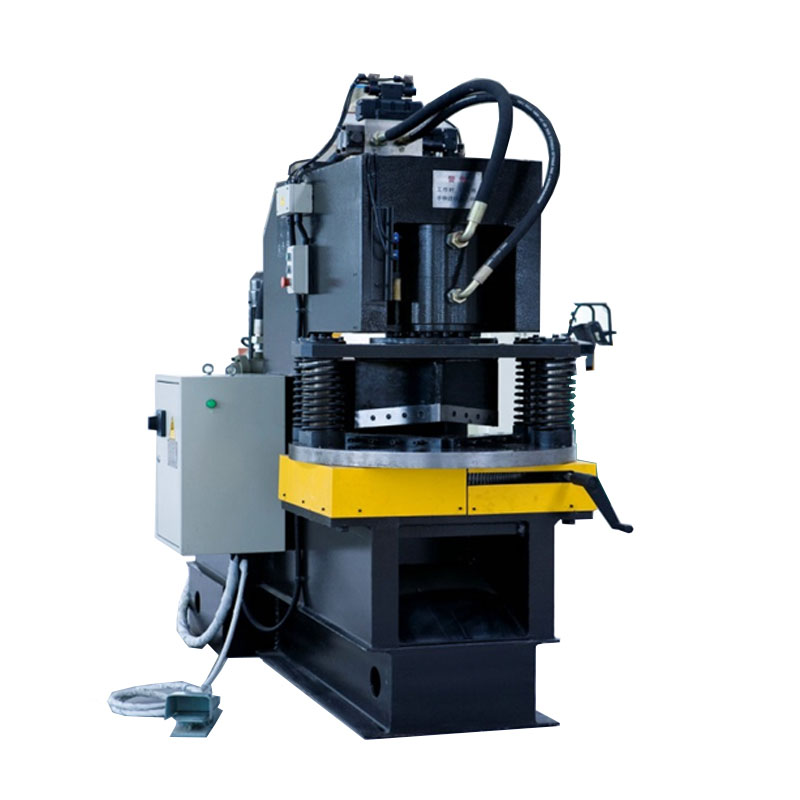

1. The machine bed of heavy load machine adopts high quality steel plate welding structure. After welding, the surface is painted, so as to improve the surface quality and antirust ability of steel plate. The welding parts of the lathe bed are heat aged to eliminate the welding stress to the maximum extent.

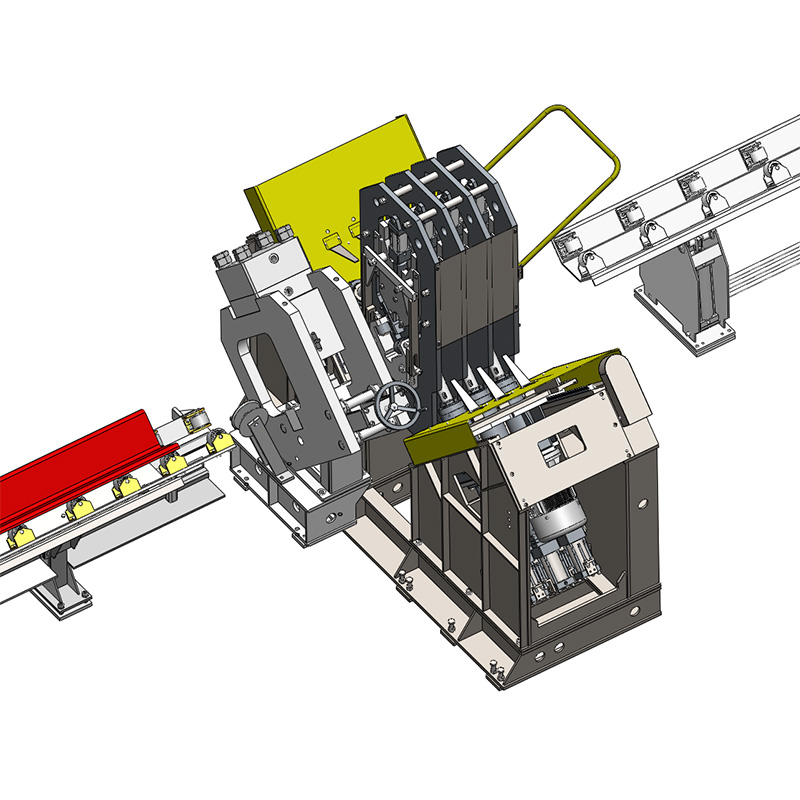

2. The machine has two CNC axes: x-axis is the left and right movement of clamp, Y-axis is the front and rear movement of clamp, and the high rigidity CNC workbench ensures the reliability and accuracy of feeding.

3. X. Y drive shaft adopts precision ball screw to ensure transmission accuracy.

4. X and Y axes adopt precision linear guide rail, with large load, high precision, long service life of guide rail, and can keep high precision of machine for a long time.

5. The x-axis and y-axis drive motors are driven by German AC servo motors. Y-axis realizes semi-closed loop position feedback.

6. The machine is lubricated by the combination of centralized lubrication and decentralized lubrication, so that the machine is in good working condition every time.

7. The CNC Worktable of moving material directly fixed on the foundation, and the worktable is equipped with a universal conveying ball, which has the advantages of small resistance, low noise and easy maintenance.

8. The punching die position of the machine adopts double row linear arrangement, and the maximum punching diameter is 50mm. The piston of the hydraulic cylinder drives the slide block guided by two linear rolling guides to move up and down, which ensures the accurate alignment of the die and the punch, and has long service life. The selection of punching die position adopts the way of cylinder pushing and pulling cushion block, which has the advantages of fast die changing, high reliability and convenient maintenance.

9. The material is clamped by three powerful hydraulic clamps, which can move and locate quickly. The clamp can float up and down with the fluctuation of the material. The distance between the clamps can be adjusted according to the length of the clamping edge of the material.

10. It has the advantages of short processing time, quick positioning, simple operation, less floor space and high production efficiency.

11. The interface of the computer is in English, which is easy for operators to master.

Key outsourced components list

|

NO |

Name |

Brand |

Country |

|

1 |

CNC system |

Siemens 808D |

Germany |

|

2 |

Servo motor and Servo driver |

Siemens / Panasonic |

Germany/ Japan |

|

3 |

Linear motion guide |

HIWIN/PMI |

Taiwan, Japan |

|

4 |

Ball screw |

I+F/NEEF |

Germany |

|

5 |

Cylinder |

SMC/FESTO |

Japan /Germany |

|

6 |

Solid state relay |

Weidmuller |

Germany |

|

7 |

Drag chain |

Igus/CPS |

Germany/ South Korea |

|

8 |

Double vane pump |

Denison/Albert |

USA |

|

9 |

Hydraulic valve |

ATOS |

Italy |

|

10 |

Oil cooler |

Tongfei/Laber |

China |

|

11 |

Oil lubrication device |

Herg |

Japan |

|

12 |

Low voltage electrical components |

Schneider |

France |

Note: The above is our standard supplier. It’s subject to be replaced by same quality components of other brand if the above supplier can’t supply the components in case of any special matter.

Product detail pictures:

Related Product Guide:

We have been proud from the higher consumer gratification and wide acceptance due to our persistent pursuit of high quality both on product or service and service for Factory Price Truck Beams – PPL1255 CNC Punching Machine for Plates Used for Truck Chassis Beams – FIN CNC , The product will supply to all over the world, such as: azerbaijan, Greek, Myanmar, Our market share of our products and solutions has greatly increased yearly. If you are interested in any of our products or would like to discuss a custom order, make sure you feel free to contact us. We've been looking forward to forming successful business relationships with new clients around the world in the near future. We've been looking forward to your inquiry and order.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.