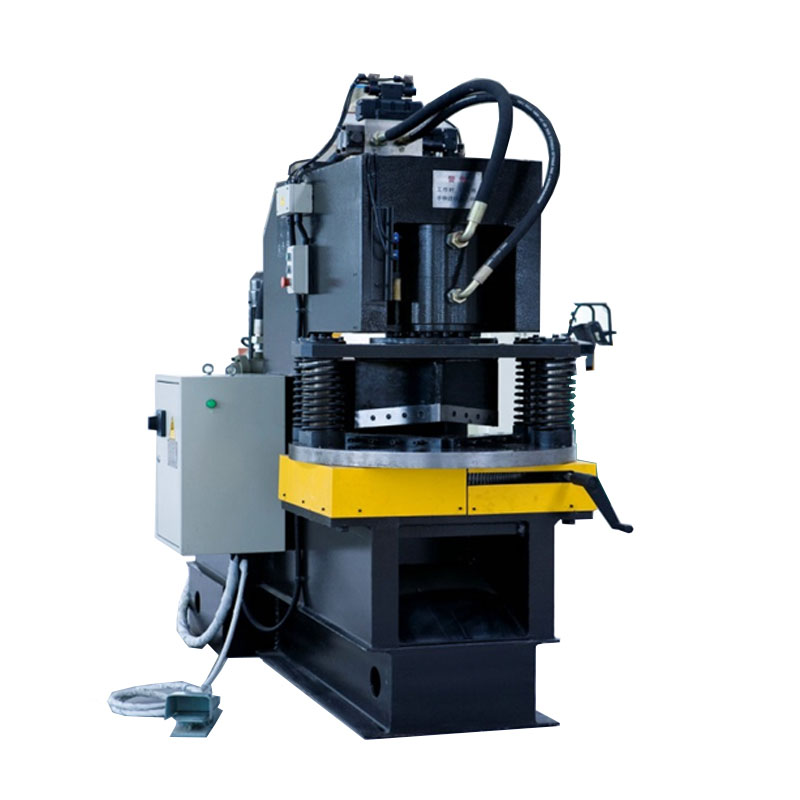

Factory Outlets Punching Machine Hydraulic - CNC High Speed Drilling Machine of Sheet Metal – FIN CNC

Factory Outlets Punching Machine Hydraulic - CNC High Speed Drilling Machine of Sheet Metal – FIN CNC Detail:

Product Parameters

| NO. | Item | Parameter |

| 1 | Processing U channel range | 63mm*40mm*4.8mm -160mm*65mm*8.5mm (Q345) |

| 2 | Maximum punching diameter | 26mm(round hole) |

| 22*60(oval hole). | ||

| 3 | Punching nominal force | 950KN |

| Cut off nominal force | 1000KN | |

| 4 | Quantity of punching head per side | 3 |

| 5 | Maximum raw material length | 12m |

| 6 | Cut off method | Single blade cutting(channel) |

| 7 | Net weight | Aabout 12000KGS |

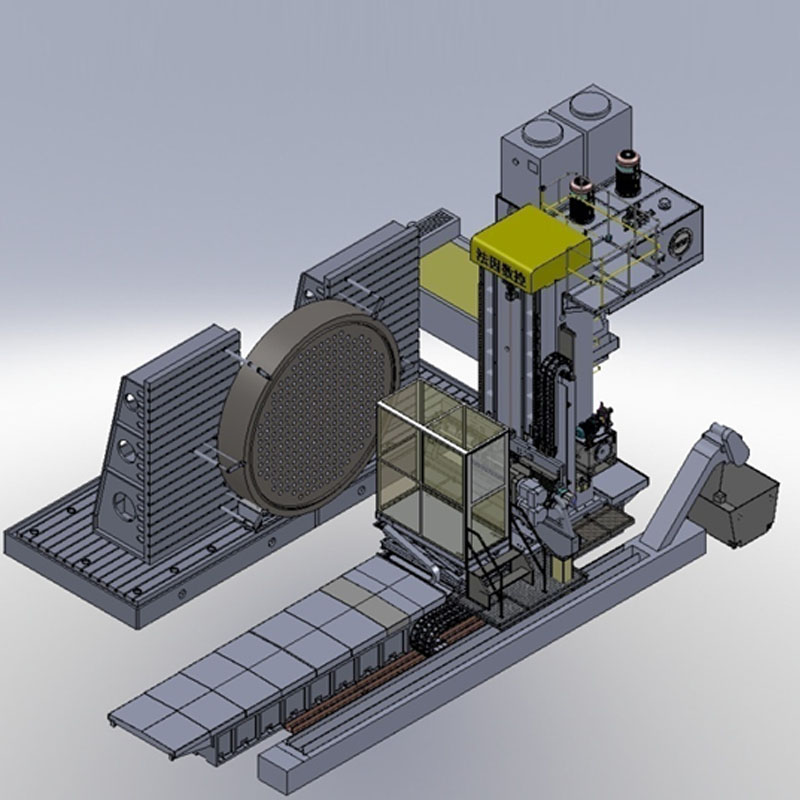

| 8 | Machine dimensions | 25mx7mx2.2m |

Details and advantages

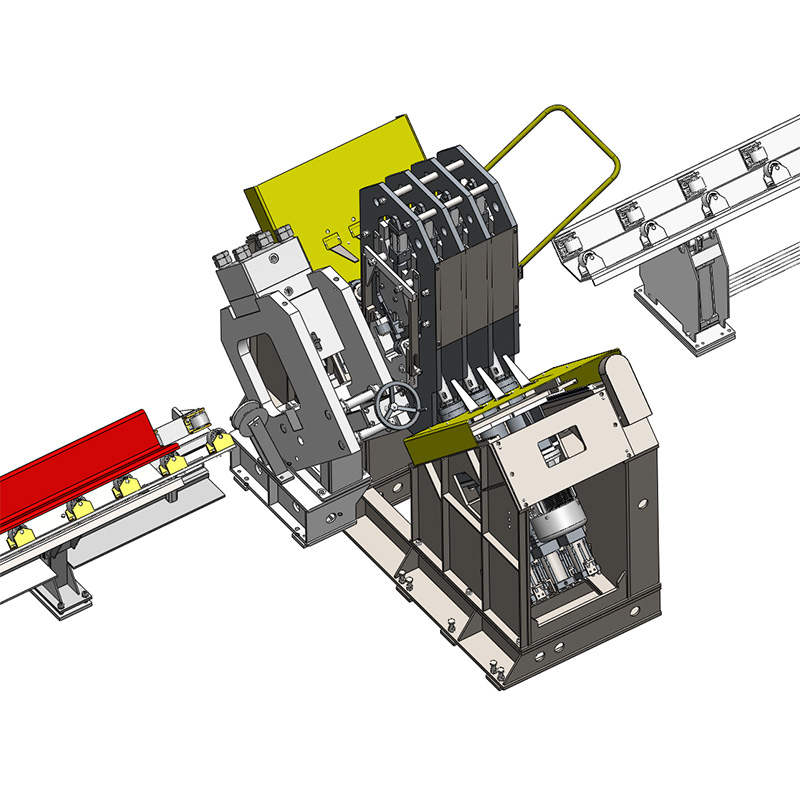

1. The punching unit adopts a closed body, which is very strong. 2. The shearing unit adopts single- blade shearing and a closed body, which realizes the shearing of different channel steels by changing the shearing die. 3. The material is clamped by pneumatic clamps, moving and positioning quickly. 4. The loading bed is composed of four chains with shift blocks and a frame body. The chains are driven by a motor through a speed reducer. 5. The rotating feeder is driven by a motor through a speed reducer and a chain, which rotates and feeds the material on the horizontal feed channel into the longitudinal feed channel. 6. The discharge material channel is composed of material channel body and cylinder. The finished material is sent out of the production line by its rotation after the main machine part comes out. 7. This machine has two CNC axes: the movement and positioning of the feeding trolley, and the up and down movement and positioning of the punching unit die. 8. Computer programming is easy, and it can display the coordinate size of the material figure and the hole position, which is convenient for inspection. The use of host computer management greatly facilitates the storage and calling of programs; the display of graphics; fault diagnosis and remote communication.

Key Outsourced Components List

| NO. | Name | Brand | Origin |

| 1 | AC servo motor | Panasonic | Taiwan, China |

| 2 | PLC | Mitsubishi | |

| 3 | Electromagnetic unloading valve | ATOS/YUKEN | Italy / Taiwan, China |

| 4 | Relief valve | ATOS/YUKEN | Taiwan, China USA |

| 5 | Electro hydraulic directional valve | JUSTMARK | |

| 6 | Double vane pump | ALBERT | |

| 7 | Converge | AirTAC | Taiwan, China Japan China |

| 8 | Air valve | AirTAC | |

| 9 | Cylinder | SMC/CKD | |

| 10 | Duplex | SMC/CKD | |

| 11 | Computer | LENOVO | |

| 12 | Electromagnetic unloading valve | ATOS/YUKEN | Italy / Taiwan, China |

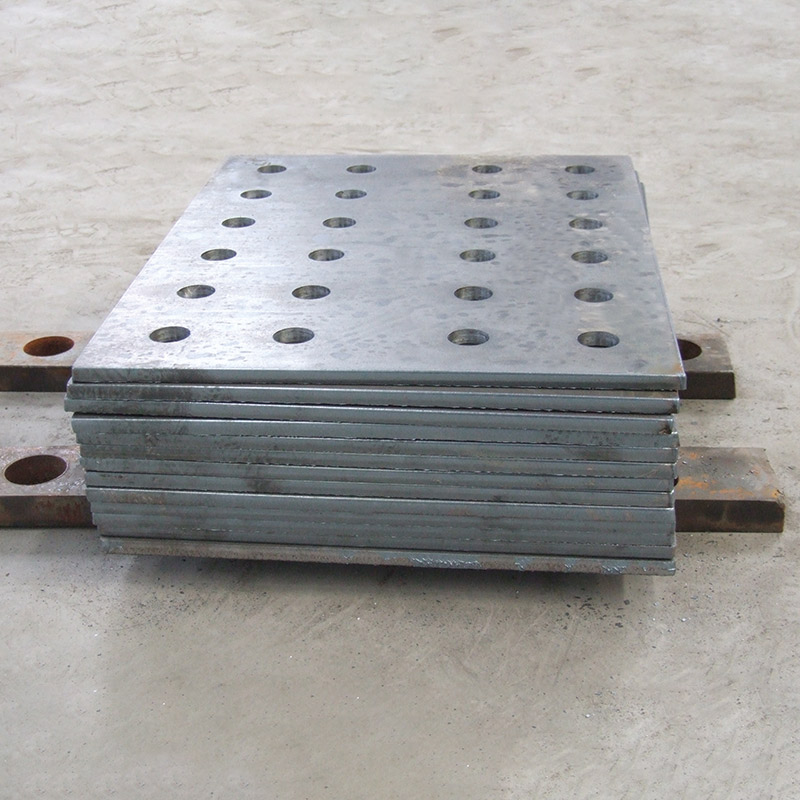

Product detail pictures:

Related Product Guide:

We always work as a tangible team to ensure that we can provide you with the best quality and the best price for Factory Outlets Punching Machine Hydraulic - CNC High Speed Drilling Machine of Sheet Metal – FIN CNC , The product will supply to all over the world, such as: Anguilla, Ethiopia, Niger, We attained ISO9001 which provides solid foundation for our further development. Persisting in "High quality, Prompt Delivery, Competitive Price", we have established long-term cooperation with clients from both overseas and domestically and get new and old clients' high comments. It is our great honor to meet your demands. We are sincerely expecting your attention.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.