Chinese wholesale Steel Tower - PLD7030-2 Gantry Mobile CNC Plate Drilling Machine – FIN CNC

Chinese wholesale Steel Tower - PLD7030-2 Gantry Mobile CNC Plate Drilling Machine – FIN CNC Detail:

Product Parameters

| Item name | Parameter | ||

| PLD3030A | PLD4030 | ||

| Maximum machining plate size | Length x Width | 3000x3000mm | 4000*3000mm |

| Thickness | 200mm | 100mm | |

| Work table | T-groove width dimension | 22mm | |

| Drilling power head | Quantity | 2 | 1 |

| Max drilling hole diameter | Φ12mm-Φ50mm | ||

| RPM (frequency conversion) | 120-450r/min | ||

| Morse taper of spindle | NO. 4 | ||

| Spindle motor power | 2x7.5kW | 5.5KW | |

| Distance from lower end face of spindle to worktable | 200-550mm | ||

| Gantry longitudinal movement (X-axis) | X-axis travel | 3000mm | |

| X-axis moving speed | 0-8m/min | ||

| X-axis servo motor power | 2x2.0kW | ||

| X-axis positioning accuracy | 0.1mm/Whole | ||

| Lateral movement of power head (Y-axis) |

Maximum distance between two power heads of Y axis | 3000mm | |

| Minimum distance between two power heads of Y axis | 470mm | ||

| Y-axis servo motor power | 1.5KW | ||

| Feed motion of power head | Z-axis travel | 350mm | |

| Z-axis servo motor power | 2*2KW | ||

| Chip conveyor and cooling | Chip conveyor motor power | 0.75KW | |

| Cooling pump motor power | 0.45KW | ||

| Electrical system | Total motor power | About 30kW | About 20kW |

| Overall dimensions of machine tool | About 6970x6035x2990mm | ||

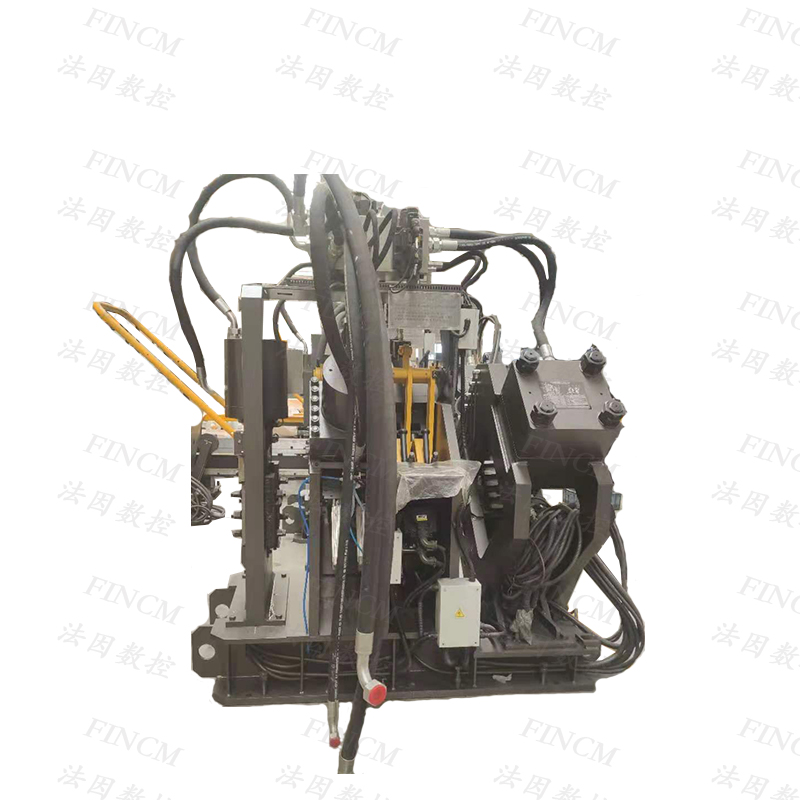

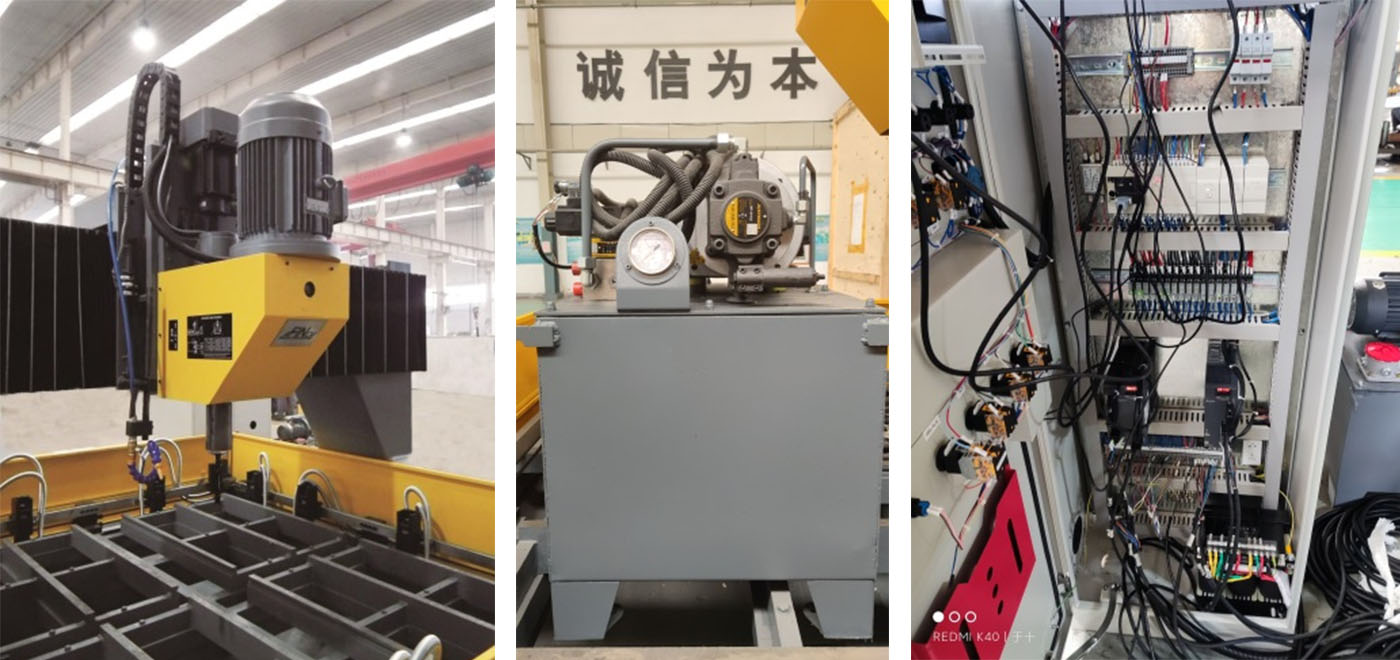

Details and advantages

1. The maximum drilling diameter of the machine tool is 50mm, the maximum drilling plate thickness is 200mm, and the maximum plate size is 3000x3000mm.

2. The machine tool is equipped with two independent servo feed slide drilling power heads.

3. The coordinate position of the hole can be quickly positioned at the speed of 8m / min, and the auxiliary time is relatively short.

4. The spindle motor of drilling power head adopts stepless frequency conversion speed regulation, and the feed speed adopts servo stepless speed regulation, which is convenient to operate.

5. After the drilling feed stroke is set, it has the automatic control function.

6. The taper hole of the spindle is Morse No. 4, and is equipped with Morse No. 4 / 3 reducer sleeve, which can install drill bits with different diameters.

7. The gantry mobile structure is adopted, the machine covers a small area and the structural layout is reasonable.

8. The X-axis movement of gantry adopts high bearing capacity linear rolling guide rail pair guidance, which is flexible.

9. The machine is equipped with a spring center tool setting device, which can easily identify the position of the plate.

10. The control system adopts the upper computer programming software independently developed by our company and matched with PLC programmable controller, with a high degree of automation.

11. The machine guide rail and lead screw nut are equipped with automatic lubrication device.

12. X-axis guide rail adopts stainless steel telescopic protective cover, both sides of y-axis guide rail adopt flexible protective cover, and waterproof baffle is added around the workbench.

Key outsourced components list

|

NO. |

Name |

Brand |

Country |

|

1 |

Linear guide rail |

HIWIN/PMI |

Taiwan, China |

|

2 |

Servo driver |

Mitsubishi |

Japan |

|

3 |

Servo motor |

Mitsubishi |

Japan |

|

4 |

Programmable controller |

Mitsubishi |

Japan |

|

5 |

Automatic lubrication device |

BIJUR/HERG |

USA / Japan |

|

6 |

Computer |

Lenovo |

China |

Note: The above is our standard supplier. It’s subject to be replaced by same quality components of other brand if the above supplier can’t supply the components in case of any special matter.

Product detail pictures:

Related Product Guide:

Sticking to your belief of "Creating solutions of high quality and generating buddies with people from all around the world", we always put the fascination of customers to start with for Chinese wholesale Steel Tower - PLD7030-2 Gantry Mobile CNC Plate Drilling Machine – FIN CNC , The product will supply to all over the world, such as: Turkmenistan, Vietnam, Lyon, Our company will continue to serve customers with best quality, competitive price and timely delivery & the best payment term! We sincerely welcome friends from all over the world to visit& cooperate with us and enlarge our business. If you are interested in our products, please do not hesitate to contact us, we will be happy to provide you with further information!

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly