China Cheap price Angle Cut Corner - DJ1000C FINCM Automatic CNC Metal Cutting Band Saw Machine – FIN CNC

China Cheap price Angle Cut Corner - DJ1000C FINCM Automatic CNC Metal Cutting Band Saw Machine – FIN CNC Detail:

Product parameter

|

Series No. |

Item name |

Parameter |

|

|

1 |

Dimension of H-beam sawing (without turning angle) Section height × Flange width (mm) |

MAX.1000 mm×500 mm |

|

|

2 |

MIN.200 mm×75 mm |

||

|

3 |

Hacksaw blade |

T:1.6mm W:54mm |

|

|

4 |

Motor power |

Main motor |

11 kW |

|

5 |

Hydraulic pump |

5.5kW |

|

|

6 |

CNC Carriage |

Servo motor power |

5.0kW |

|

7 |

Moving speed |

0~20m/min |

|

|

8 |

Maximum weight |

10t |

|

|

9 |

Linear speed of saw blade |

20~100 m/min |

|

|

10 |

Cutting feed rate |

program control |

|

|

11 |

Oblique cutting angle |

0°~45° |

|

|

12 |

Work Table height |

800 mm |

|

|

13 |

Main clamping hydraulic motor |

100ml/r |

|

|

14 |

Front clamping hydraulic motor |

100ml/r |

|

|

15 |

Overall dimension of main engine |

About 4050x2300x2700mm |

|

|

16 |

Spindle weight |

About 8800kg |

|

Details and advantages

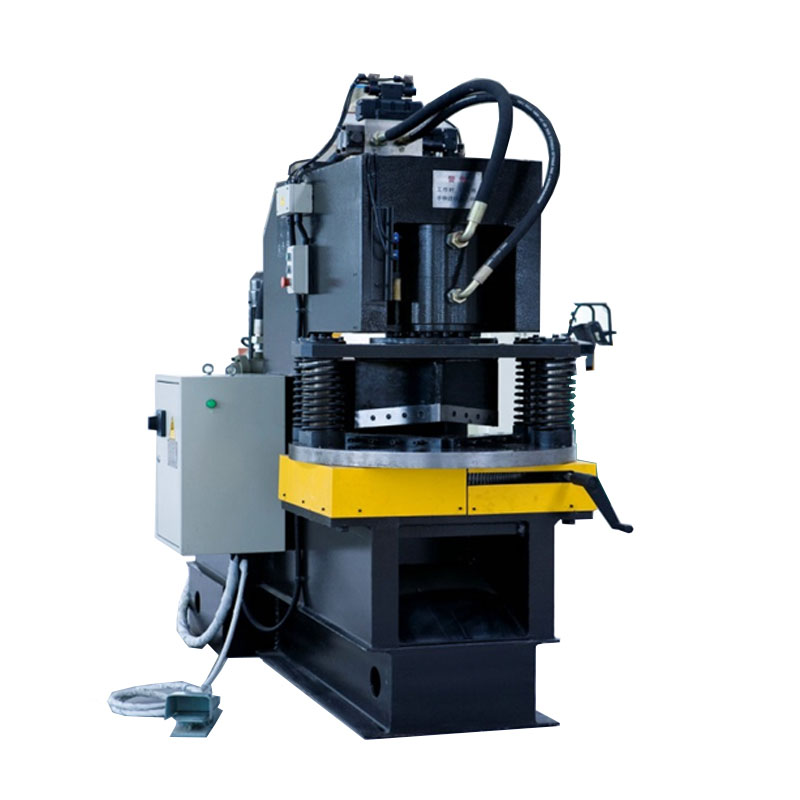

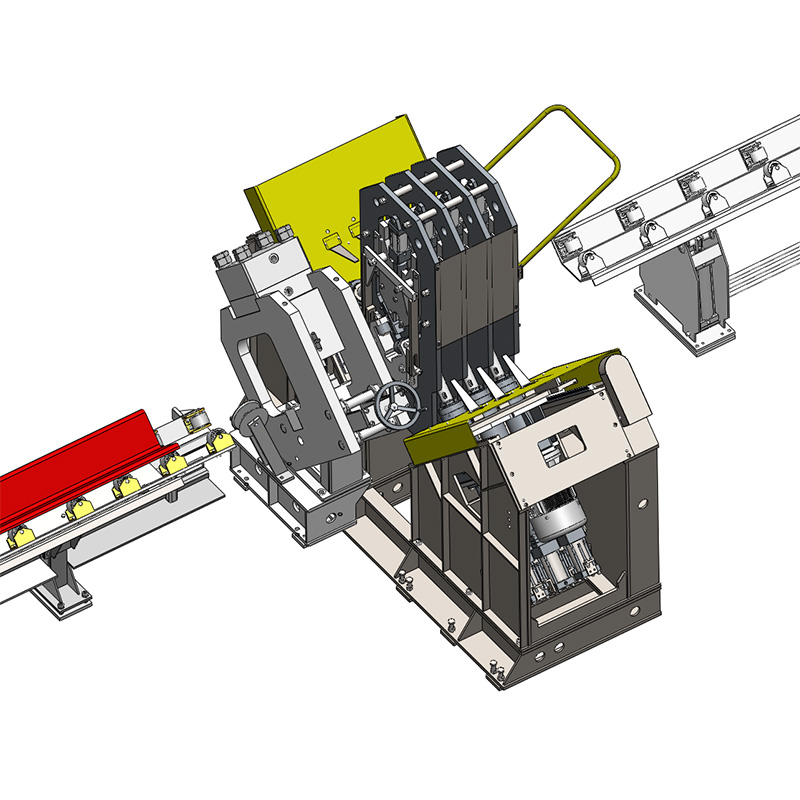

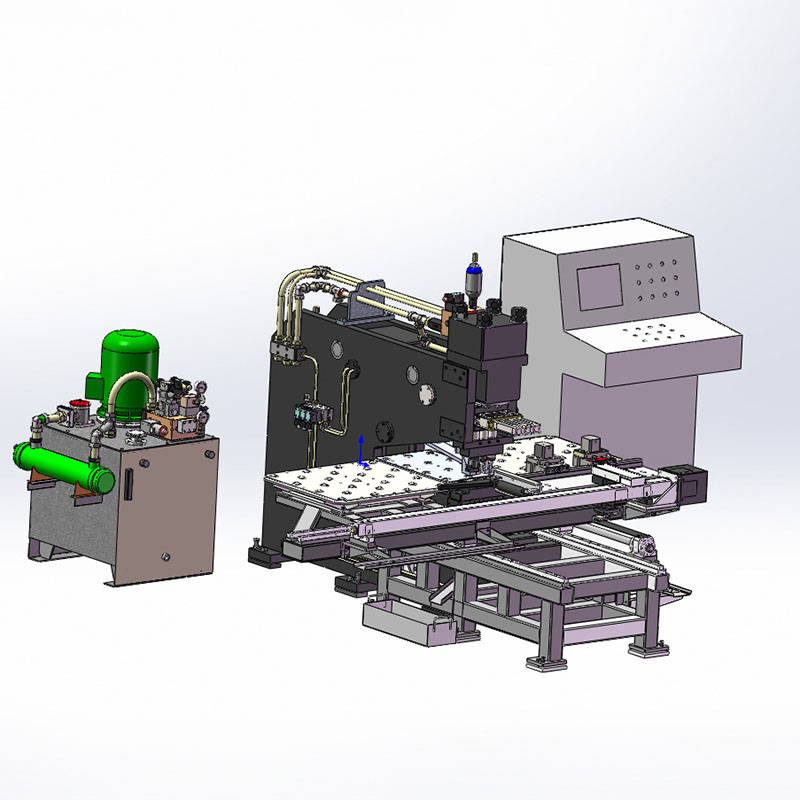

1.CNC Metal Band Saw machine is mainly composed of CNC feeding car, main machine, hydraulic system, electrical system and pneumatic system

2.The saw frame has good rigidity and longest durability under the condition of high cutting load and blade tension.

3.The saw frame adopts hydraulic servo proportional valve and encoder, which can realize digital feeding.

4.The machine tool has the main motor current detection function, when the motor overload operation, This sawing machine can use part reciprocating cutting function to prevent the saw from clamping.

5.The rotary table adopts frame structure, with good rigidity, strong stability and smooth sawing section.

6.The band saw blade adopts hydraulic tension, which can maintain good tension force in rapid movement, extending the service life of the saw blade.

7.Sawdust automatic cleaning system is equipped with a power rotary brush on the saw blade frame to automatically clean the iron chips that may stick to the saw blade after cutting.

8.The machine has the turning function of turning 0°~45°: the material does not move but the whole machine rotates, then 0 °~ 45° Any angle between them.

Key sourced components

|

NO. |

Name |

Band |

Country |

|

1 |

linear guide rail |

HIWIN/CSK |

Taiwan(China) |

|

2 |

Hydraulic motor |

Justmark |

Taiwan(China) |

|

3 |

Magnescale |

SIKO |

Germany |

|

4 |

Hydraulic pump |

Justmark |

Taiwan(China) |

|

5 |

Electromagnetic hydraulic valve |

ATOS/YUKEN |

Italy / Japan |

|

6 |

Proportional valve |

ATOS |

Italy |

|

7 |

Saw blade |

LENOX/WIKUS |

USA / Germany |

|

8 |

Frequency converter |

INVT/INOVANCE |

China |

|

9 |

Programmable controller |

Mitsubishi |

Japan |

|

10 |

Servo motor |

PANASONIC |

Japan |

|

11 |

Servo driver |

PANASONIC |

Japan |

|

12 |

Touch screen |

Panel |

Taiwan(China) |

Note: The above is our fixed supplier. It’s subject to be replaced by same quality components of other brand if the above supplier can’t supply the components in case of any special matter.

Product detail pictures:

Related Product Guide:

It really is a good way to further improve our goods and service. Our mission would be to acquire inventive items to buyers with a very good encounter for China Cheap price Angle Cut Corner - DJ1000C FINCM Automatic CNC Metal Cutting Band Saw Machine – FIN CNC , The product will supply to all over the world, such as: Jakarta, Bahrain, Washington, Certainly, competitive price, suitable package and timely delivery will be assured as per customers' demands. We sincerely hope to build business relationship with you on the basis of mutual benefit and profit in the very near future. Warmly welcome to contact us and become our direct cooperators.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!