Cheapest Price Saw Cutting Machine - PP153 CNC Hydraulic Press Plate Punching Machine – FIN CNC

Cheapest Price Saw Cutting Machine - PP153 CNC Hydraulic Press Plate Punching Machine – FIN CNC Detail:

Product Parameter

|

NO. |

Item name |

Parameter |

||

|

1 |

Punching capacity |

1500KN | ||

|

2 |

Maximum plate size |

1500*775mm | ||

|

3 |

Plate thickness range |

5~25mm | ||

|

4 |

Station |

Number of punching and marking dies |

3 | |

|

5 |

Processing capacity |

Maximum punch diameter |

φ30mm | |

|

6 |

For Q345 steel, σ B ≤ 610mpa, φ 30*25mm (diameter* thickness) For Q420 steel, σ B ≤ 680mpa, φ 26*25mm (diameter* thickness) |

|||

|

7 |

Marking ability |

Marking ability |

800KN | |

|

8 |

Characters size |

14×10mm | ||

|

9 |

Number of characters in a group |

10 | ||

|

10 |

Minimum hole margin |

25mm | ||

|

11 |

Number of clamps |

2 | ||

|

12 |

System pressure |

High pressure |

24Mpa |

|

|

13 |

Low pressure |

6Mpa |

||

|

14 |

Air pressure |

0.5Mpa |

||

|

15 |

Motor power of hydraulic pump |

22KW |

||

|

16 |

Number of NC axes |

2 |

||

|

17 |

X. Y-axis speed |

18m/min |

||

|

18 |

X-axis servo motor power |

2KW |

||

|

19 |

Y-axis servo motor power |

2KW |

||

|

20 |

Cooling mode |

Water-cooling |

||

|

21 |

Total power |

26KW |

||

|

22 |

Machine dimensions (L*W*H) |

3650*2700*2350mm | ||

|

23 |

Machine weight |

9500Kg |

||

Details and advantages

1. The PP153 CNC hydraulic punching machine has a punching tonnage of up to 1500KN. It has three die positions and can be equipped with three sets of punching dies, or only two sets of punching dies and a character box. The die is easy to replace and the print is clear.

2. The bed of the heavy-duty machine tool adopts a high-quality steel plate welded structure. After welding, the surface is painted,

Thereby, the surface quality and anti-rust ability of the steel plate are improved. The bed welding parts are heat-aged to minimize welding stress. As a result, the reliability and durability of the machine tool are improved.

3. Both X and Y axes use precision linear guide rails, which have large load, high precision and long service life of the guide rails.

And can maintain the high precision of the machine tool for a long time.

4. Use the combination of centralized lubrication and distributed lubrication to lubricate the machine tool, so that the machine tool can be lubricated.Always in good working order.

5. The plate is clamped by two powerful hydraulic clamps and moves quickly for positioning. The clamp can be adjusted with the plate.

Ups and downs, up and down. The distance between the two clamps can be adjusted arbitrarily according to the length of the plate clamping side.

6. The plate processing and positioning is fast, the operation is simple, the floor space is small, and the production efficiency is high.

Key outsourced components

|

NO. |

Name |

Brand |

Country |

|

1 |

AC servo motor |

Delta |

Taiwan, China |

|

2 |

PLC |

Delta |

|

|

3 |

Electromagnetic unloading valve |

ATOS/YUKEN |

Italy / Taiwan, China |

|

4 |

Relief valve |

ATOS/YUKEN |

|

|

5 |

Electromagnetic directional valve |

JUSTMARK |

Taiwan, China |

|

6 |

Confluence plate |

SMC/CKD |

Japan |

|

7 |

Air valve |

SMC/CKD |

|

|

8 |

Cylinder |

SMC/CKD |

|

|

9 |

Duplex |

AirTAC |

Taiwan, China |

|

10 |

Computer |

Lenovo |

China |

Note: The above is our fixed supplier. It’s subject to be replaced by same quality components of other brand if the above supplier can’t supply the components in case of any special matter.

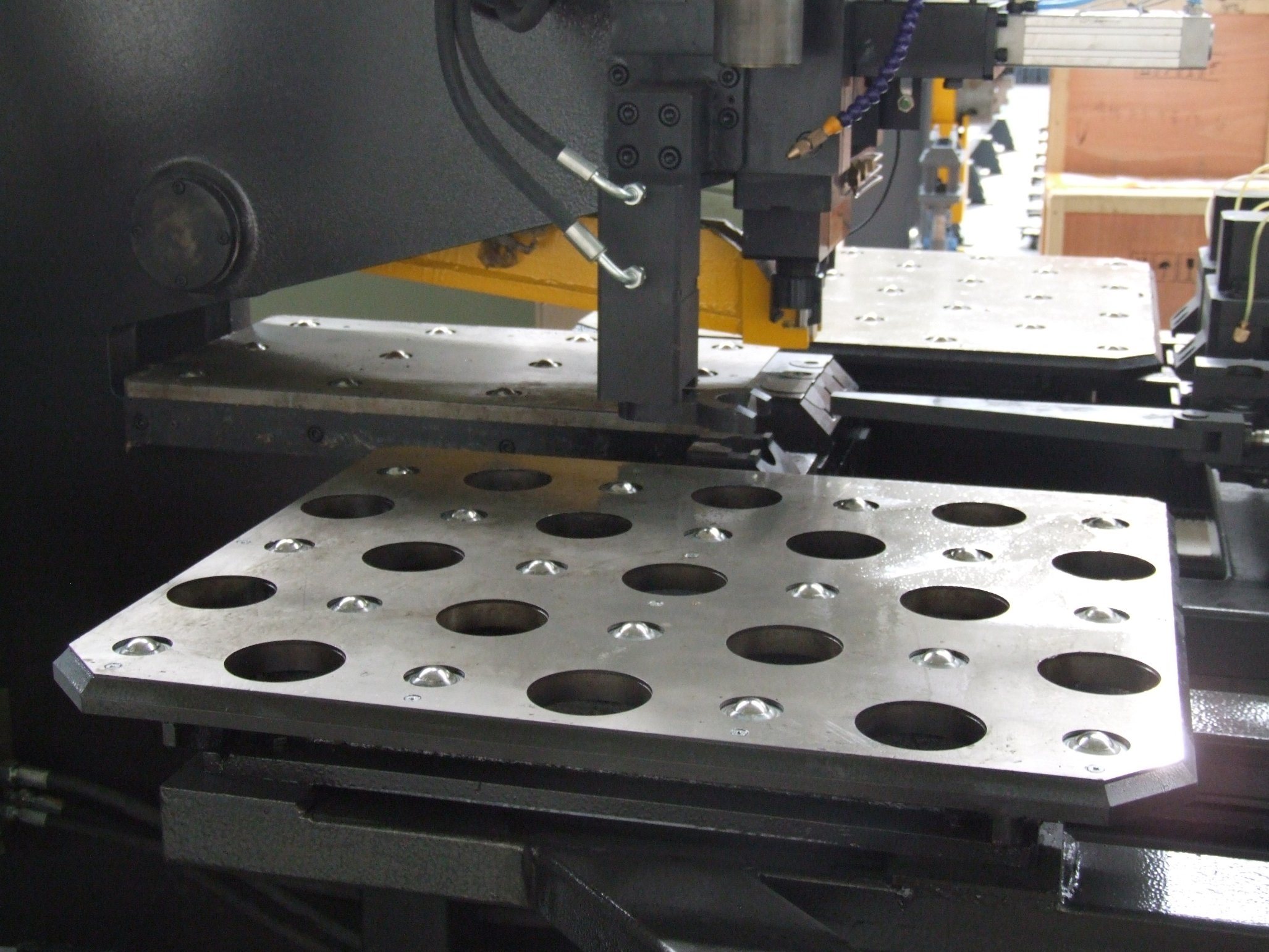

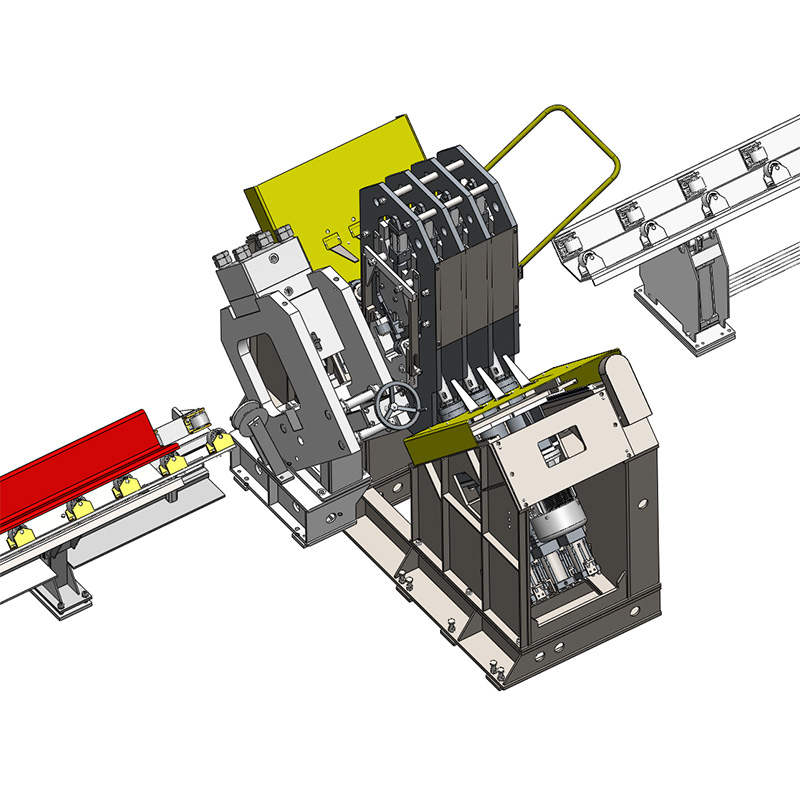

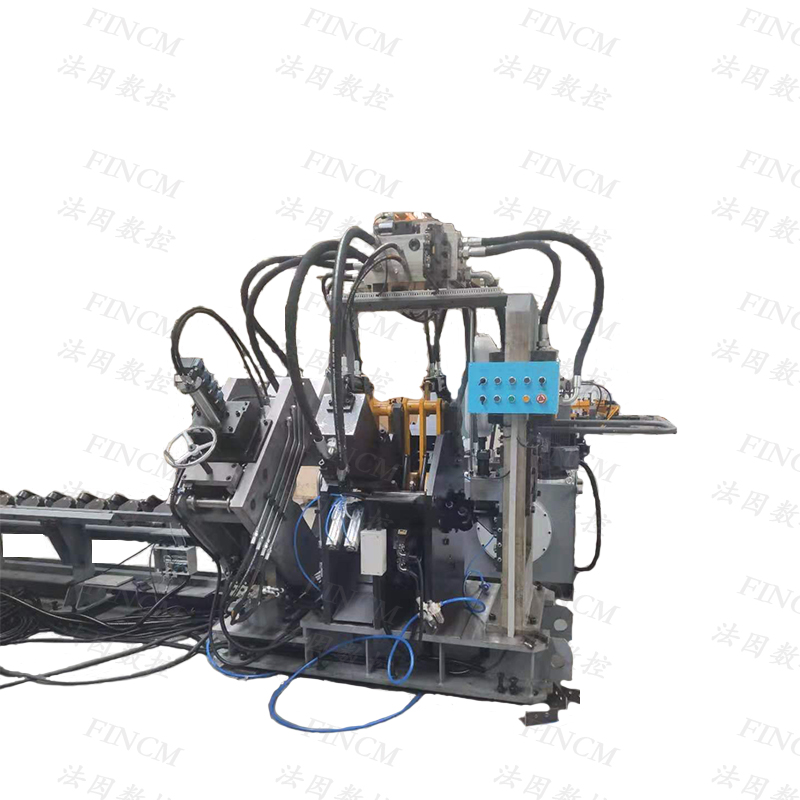

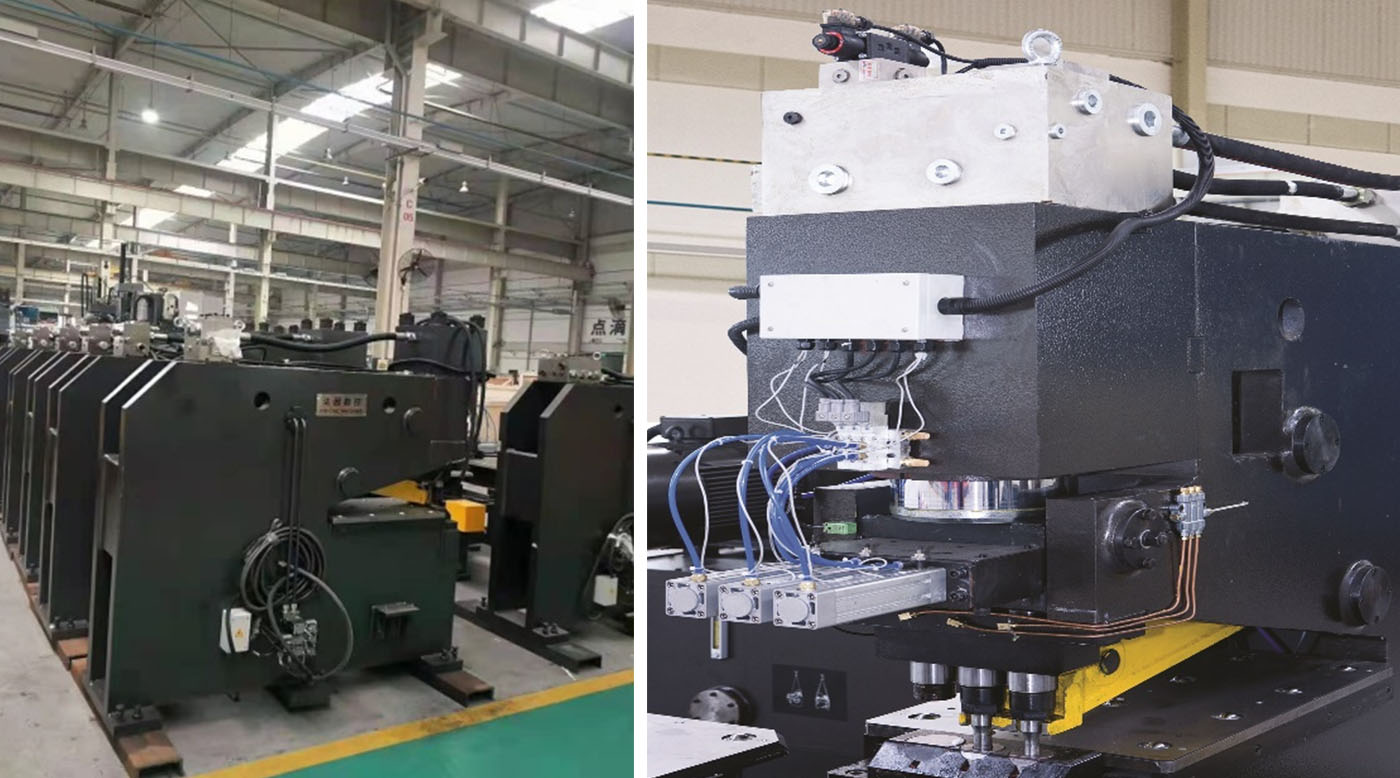

Product detail pictures:

Related Product Guide:

Our personnel are always in the spirit of "continuous improvement and excellence", and with the superior quality products, favorable price and good after-sales services, we try to win every customer's trust for Cheapest Price Saw Cutting Machine - PP153 CNC Hydraulic Press Plate Punching Machine – FIN CNC , The product will supply to all over the world, such as: Norwegian, Mauritius, Salt Lake City, Providing the best products, the most perfect service with the most reasonable prices are our principles. We also welcome OEM and ODM orders.Dedicated to strict quality control and thoughtful customer service, we are always available to discuss your requirements and ensure full customer satisfaction. We sincerely welcome friends to come negotiate business and start cooperation.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.