Cheap price Gantry CNC Milling Machine - BL2020C BL1412S CNC Angle Iron marking punching shearing machine – FIN CNC

Cheap price Gantry CNC Milling Machine - BL2020C BL1412S CNC Angle Iron marking punching shearing machine – FIN CNC Detail:

Product Parameters

|

NO. |

Item |

Parameter |

|

|

BL2020C |

BL1412S |

||

|

1 |

Processing angle steel range |

∠63×3~∠200×20 |

∠40×3 ~ ∠140×12 |

|

2 |

Maximum punching diameter |

25.5mm |

|

|

3 |

Punching nominal force |

950KN |

540KN |

|

4 |

Nominal marking force |

1030KN |

|

|

5 |

Quantity of punching head per side |

3 |

2 |

|

6 |

Maximum blank length |

12m |

|

|

7 |

Number of marking header |

4 groups |

|

|

8 |

Character size |

14*10*19mm |

|

|

9 |

Cut off method |

Double edge cutting |

|

|

10 |

Machine dimensions |

25.4mx7mx2.2m |

26mx7mx2.2m |

Details and advantages

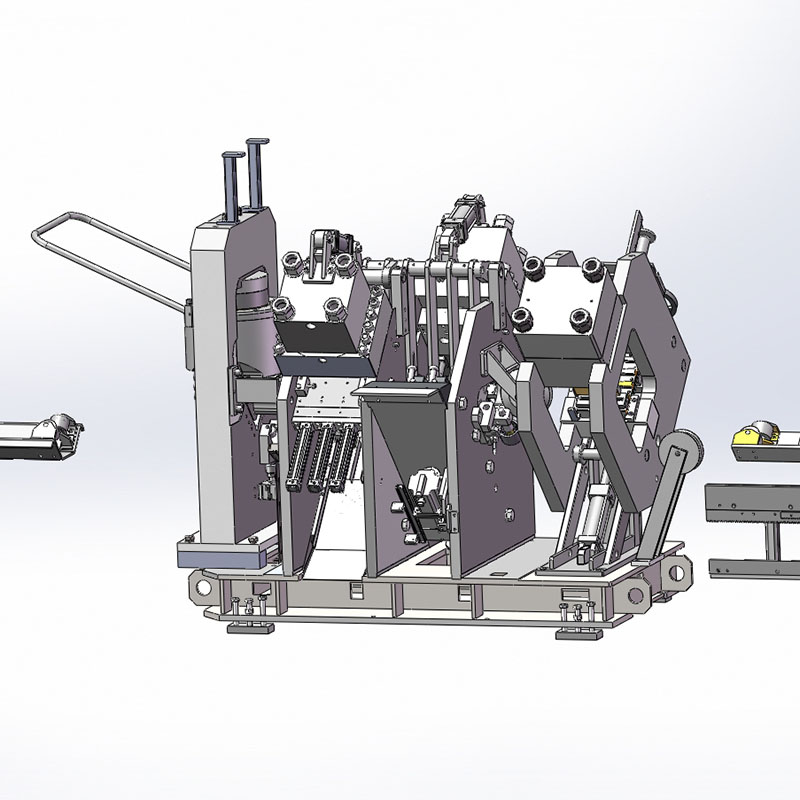

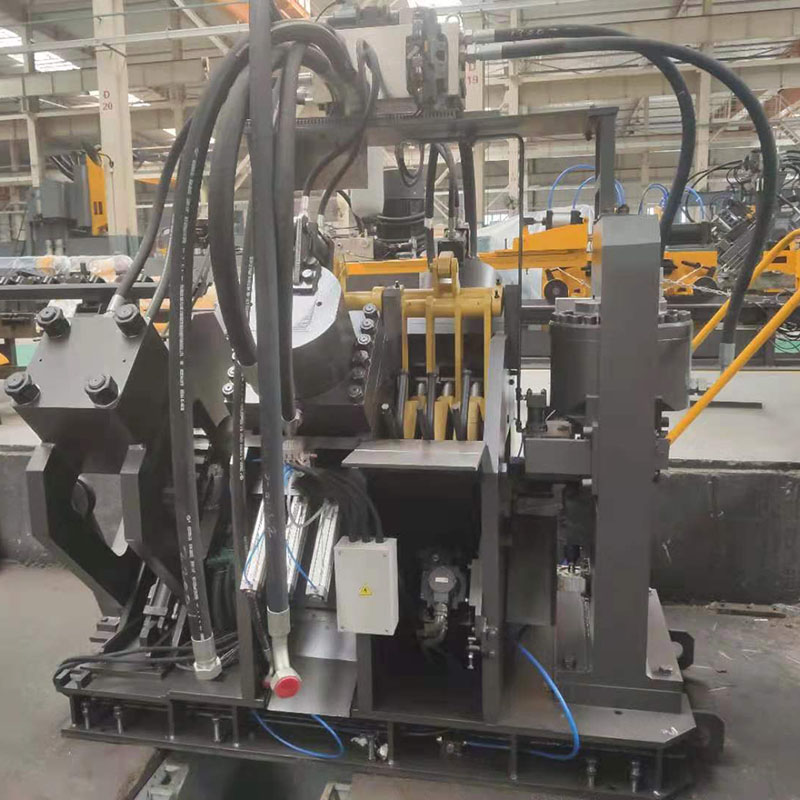

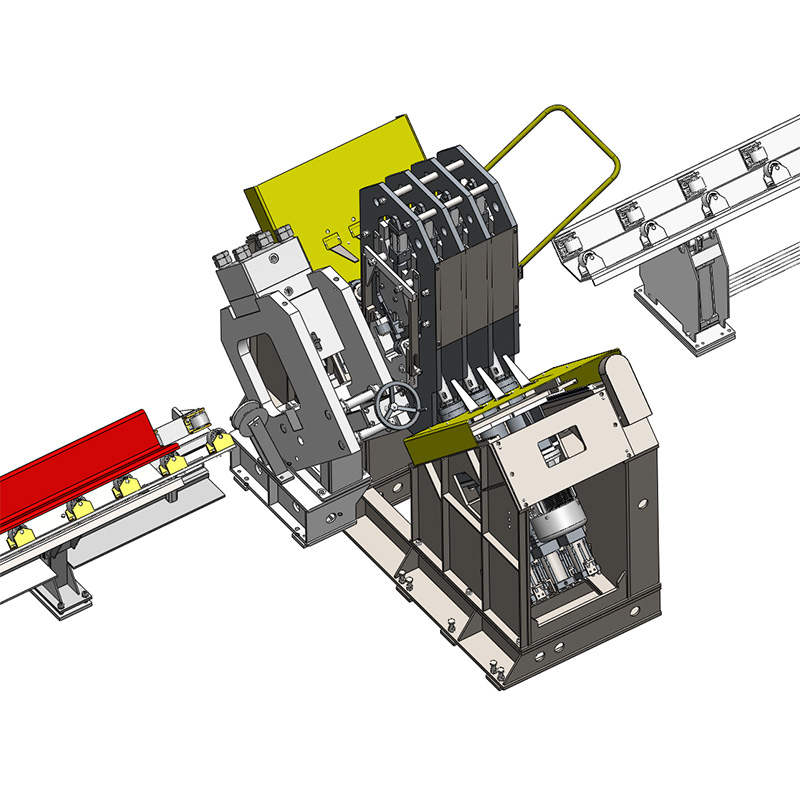

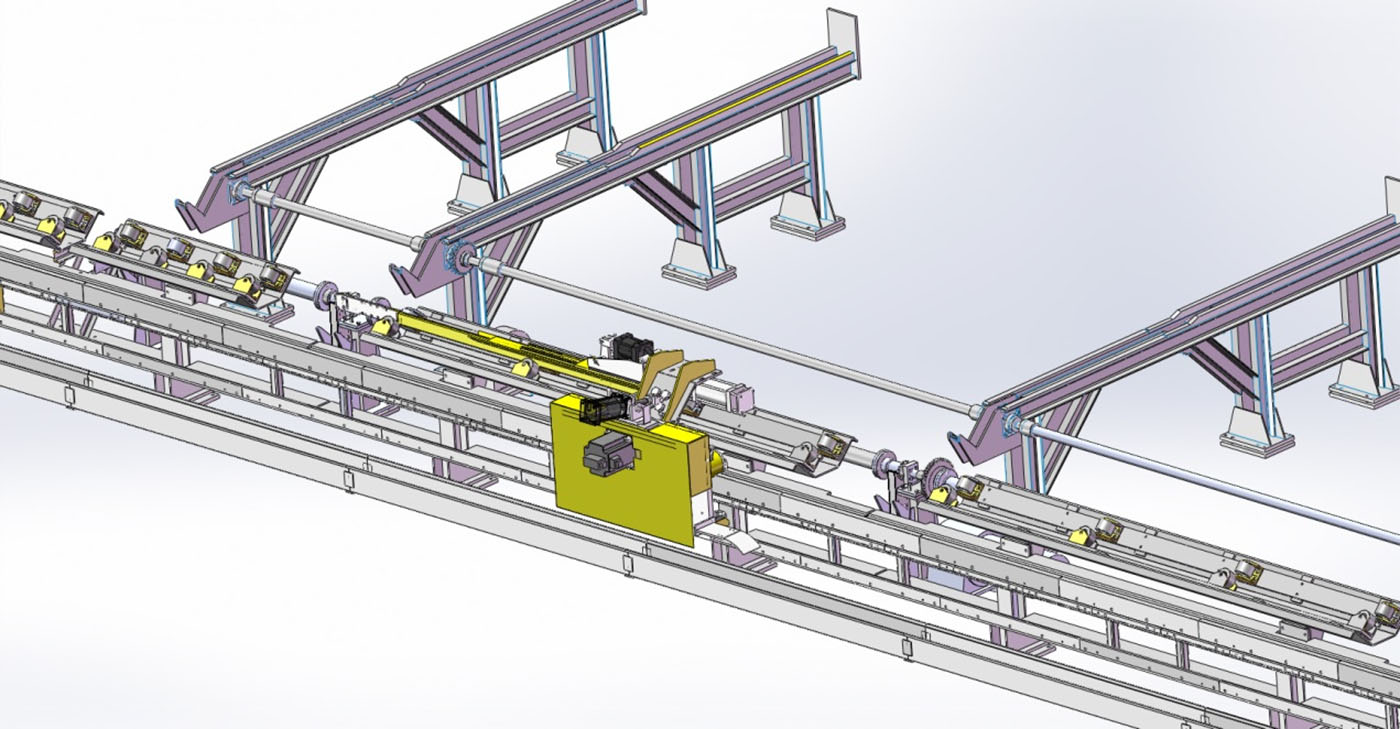

1. The main structure is composed of a marking unit, two punching units and a shearing unit.

1) The marking unit adopts a closed body, which is very strong. With four interchangeable prefix boxes, each The prefix box can hold 10 characters

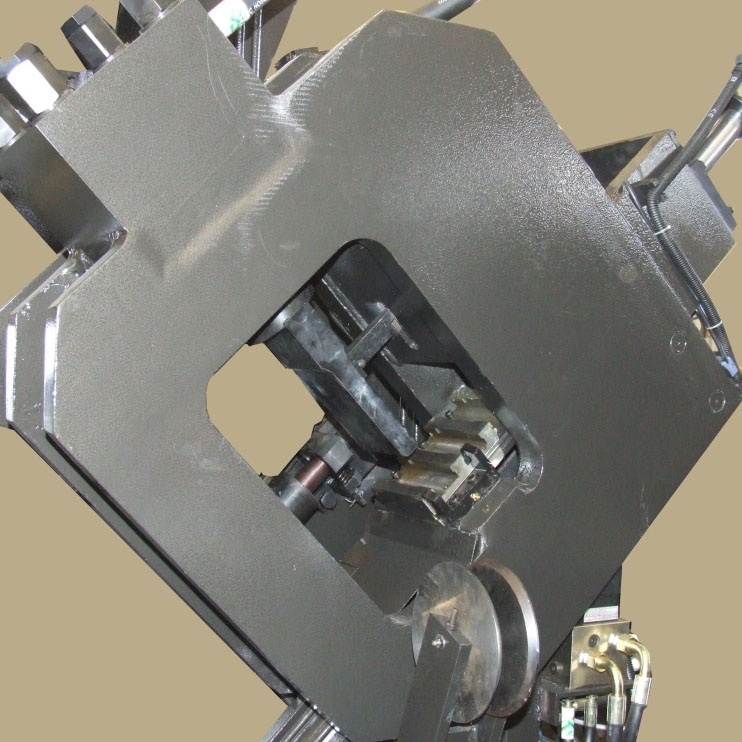

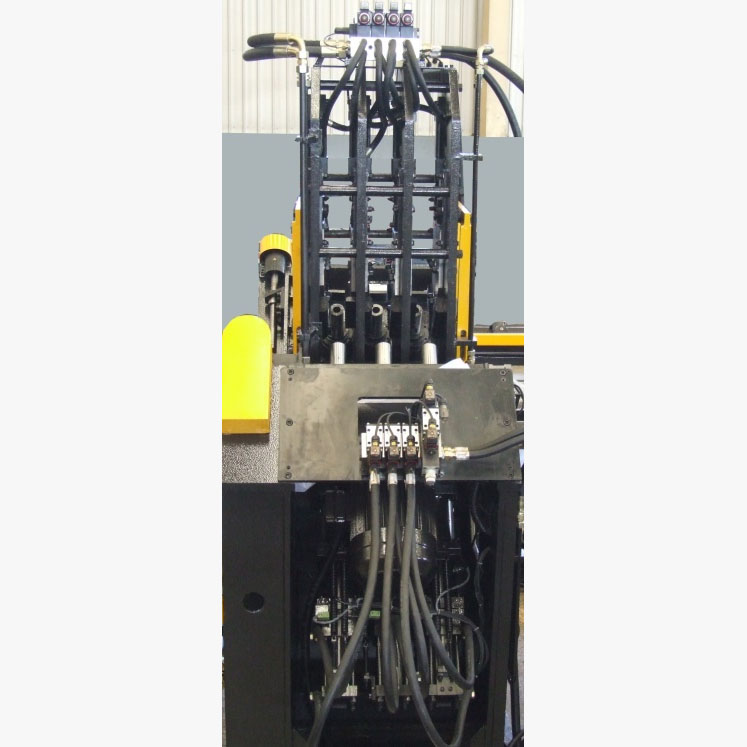

2) The punching unit adopts a closed body, which is very strong and can be installed on the closed bed Full-length material support and pressing device can ensure accurate distance. Each punching unit is equipped with Three die sets to punch three different diameter holes on each side of the angle.

The transmission changes the quasi-distance, and the quasi-distance is steplessly adjusted.

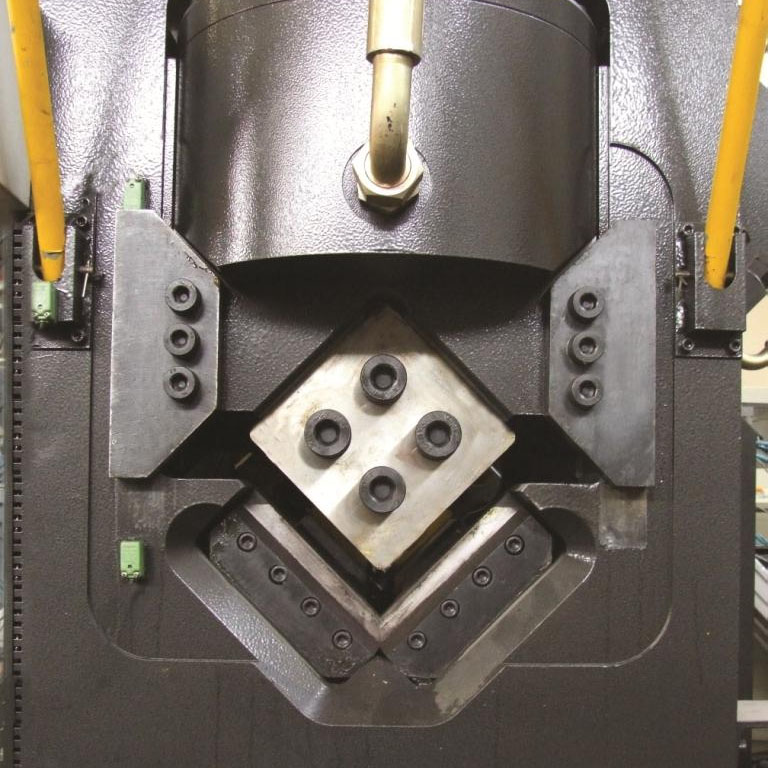

3) The shearing unit adopts a closed body, which is very strong. Double-blade shearing mechanism ensures cutting The surface is neat and the shear gap is easy to adjust. The single blade cutting mechanism ensures that the cutting section is neat and the shearing clearance is easy to adjust.

Marking unit

Punching unit

Cutting machine

2. The angle steel is clamped by pneumatic clamps and moves quickly for positioning. X-axis feeding adopts servo motor Transmission, rotary encoder feedback, full closed-loop control, high precision.

3. The transverse fore hearth is composed of four chains with dials and a frame body. The chains are decelerated by the motor machine driven.

4. The rotary feeder is driven by the motor through the reducer and the chain, and rotates the angle steel on the horizontal in-feeding material conveyor into the longitudinal conveyor.

5. The discharge material channel is composed of material channel body and cylinder. The finished angle steel is thrown out of the production line by its rotation after coming out of the main machine part.

6. The machine has three CNC axes: The movement and positioning of the feeding trolley, and the up and down movement and positioning of the die frame of the punching unit.

7. The air cylinder, solenoid valve, hydraulic valve, PLC programmable controller, servo motor, driver, etc. configured by the machine are imported parts, which are of high quality and ensure the high reliability and high precision of the equipment.

8. The computer programming is easy, and it can display the material graphics and the coordinate size of the hole position, which is convenient for inspection. The use of upper computer management greatly facilitates the storage and calling of programs; the display of graphics; fault diagnosis and remote communication.

Key Outsourced Components List

|

NO |

Name |

Brand |

Country |

| 1 |

AC servo motor |

Delta |

Taiwan, China |

| 2 |

PLC |

Delta |

|

| 3 |

Double vane pump |

Albert |

USA |

| 4 |

Electromagnetic unloading valve |

ATOS/Yuken |

Italy / Taiwan, China |

| 5 |

Relief valve |

ATOS/Yuken |

|

| 6 |

Electromagnetic relief valve |

ATOS/Yuken |

|

| 7 |

Electro hydraulic directional valve |

JUSTMARK |

Taiwan, China |

| 8 |

Electromagnetic directional valve |

JUSTMARK |

|

| 9 |

Check valve |

JUSTMARK |

|

| 10 |

Air valve |

AirTAC |

|

| 11 |

Bus bar |

AirTAC |

|

| 12 |

Air value |

AirTAC |

|

| 13 |

Cylinder |

SMC/CKD |

Japan |

| 14 |

Duplex |

SMC/ CKD |

|

| 15 |

Computer |

Lenovo |

China |

Product detail pictures:

Related Product Guide:

We emphasize advancement and introduce new products into the market each year for Cheap price Gantry CNC Milling Machine - BL2020C BL1412S CNC Angle Iron marking punching shearing machine – FIN CNC , The product will supply to all over the world, such as: Tunisia, Doha, California, Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound solutions with good logistics service and economical cost. Depending on this, our solutions are sold very well in the countries in Africa, the Mid-East and Southeast Asia.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.