Best quality Vertical Drilling Machine - PLM Series CNC Gantry mobile drilling machine – FIN CNC

Best quality Vertical Drilling Machine - PLM Series CNC Gantry mobile drilling machine – FIN CNC Detail:

Product Parameters

| Item | Name | parameter | |||

| PLM3030-2 | PLM4040-2 | PLM5050A-2 | PLM6060-2 | ||

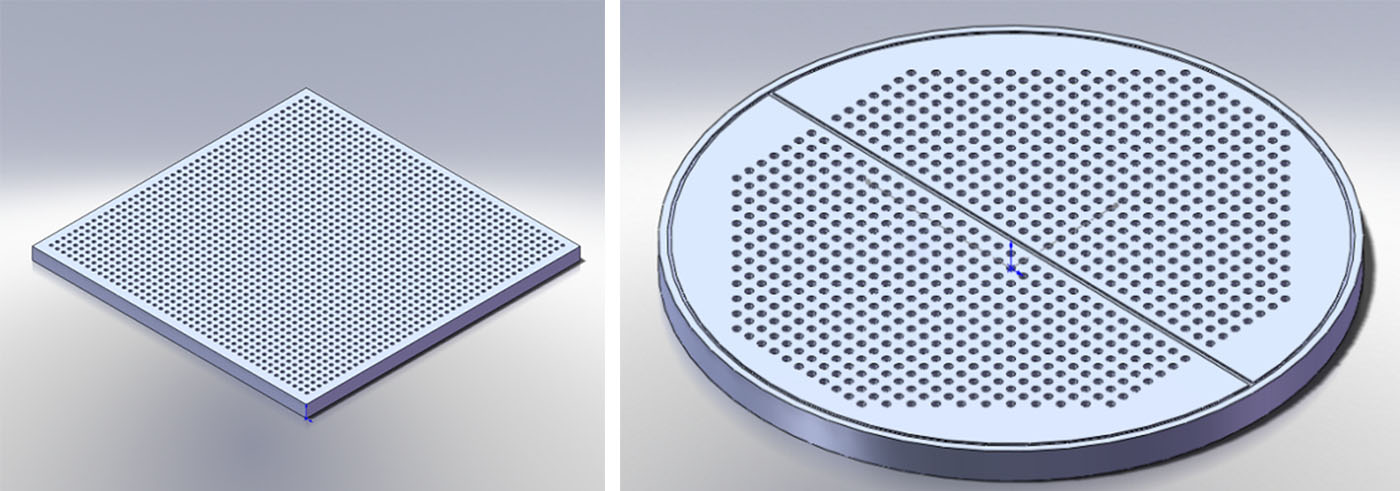

| Maximum machining material size | Length x width | 3000*3000 mm | 4000×4000 mm | 5000×5000 mm | 5000×5000 mm |

| Maximum processed plate thickness | 250 mm, Scalable to 380mm | ||||

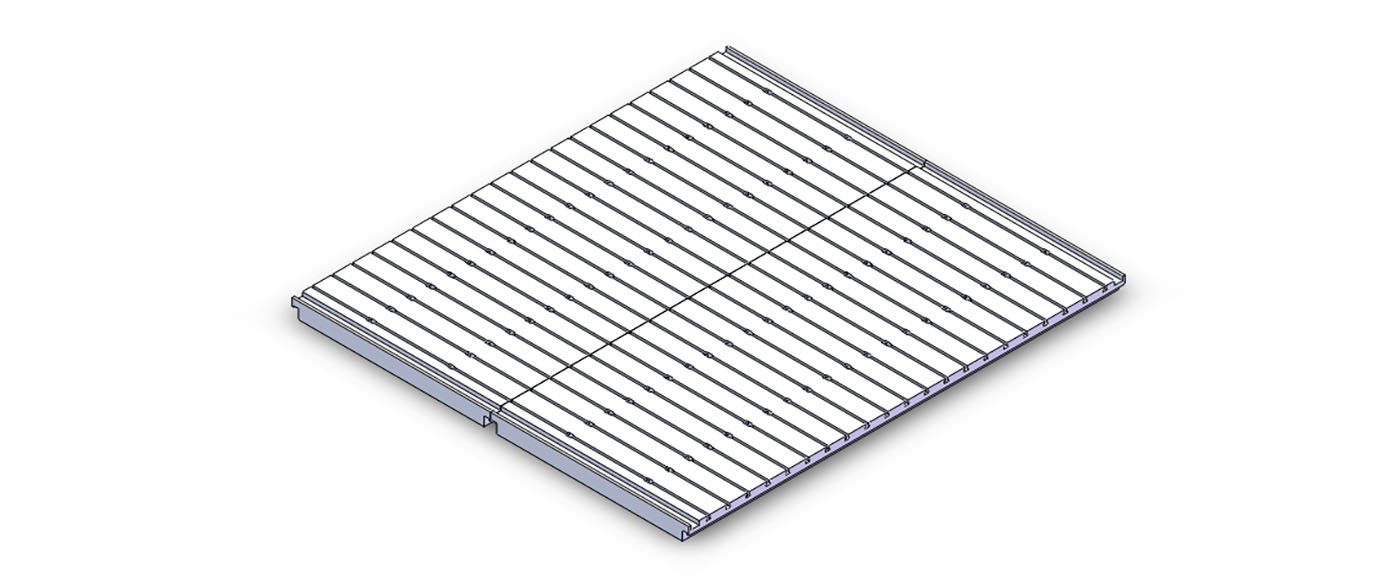

| Work table | Workbench Size | 3500×3000 mm | 4500×4000 mm | 5500×4000 mm | 5500×4000 mm |

| T-groove width | 28 mm | ||||

| Load-bearing | 3tons/㎡ | ||||

| Drilling Spindle | Maximum drilling hole diameter | φ60 mm | |||

| Maximum ratio of Tool Length vs. Hole Diameter | ≤10(Crown carbide drill) | ||||

| Spindle RPM | 30-3000 r/min | ||||

| Spindle taper | BT50 | ||||

| Spindle motor power | 2×22kW | ||||

| Maximum spindle torque n≤750r/min | 280Nm | ||||

| Distance from lower end face of spindle to worktable | 280—780 mm (Adjust according to material thickness) |

||||

| Gantry longitudinal movement (x-axis) | Maximum stroke | 3000 mm | 4000 mm | 5000 mm | |

| X-axis moving speed | 0—8m/min | ||||

| X-axis servo motor power | 2×2.7kW | ||||

| Positioning accuracy | X-axis、Y-axis | 0.06mm/ whole stroke |

0.08mm/ whole stroke |

0.10mm/ whole stroke |

|

| Repeat positioning accuracy | X-axis、Y-axis | 0.035mm/ whole stroke |

0.04mm/ whole stroke |

0.05mm/ whole stroke |

|

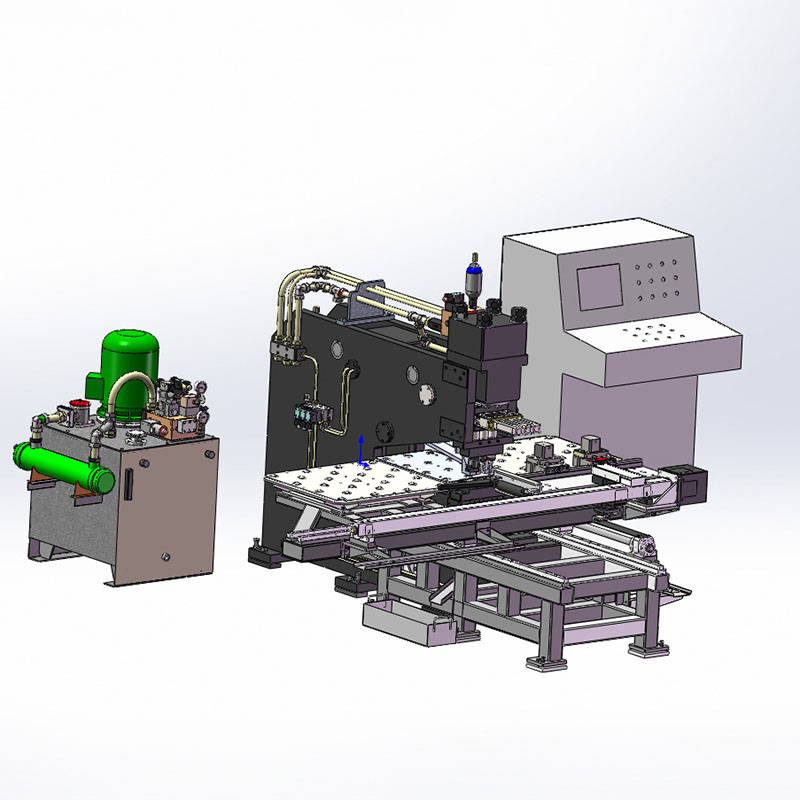

| Hydraulic system | Hydraulic pump pressure / flow | 15MPa /25L/min | |||

| Hydraulic pump motor power | 3.0 kW | ||||

| Pneumatic system | Air supply pressure | 0.5 Mpa | |||

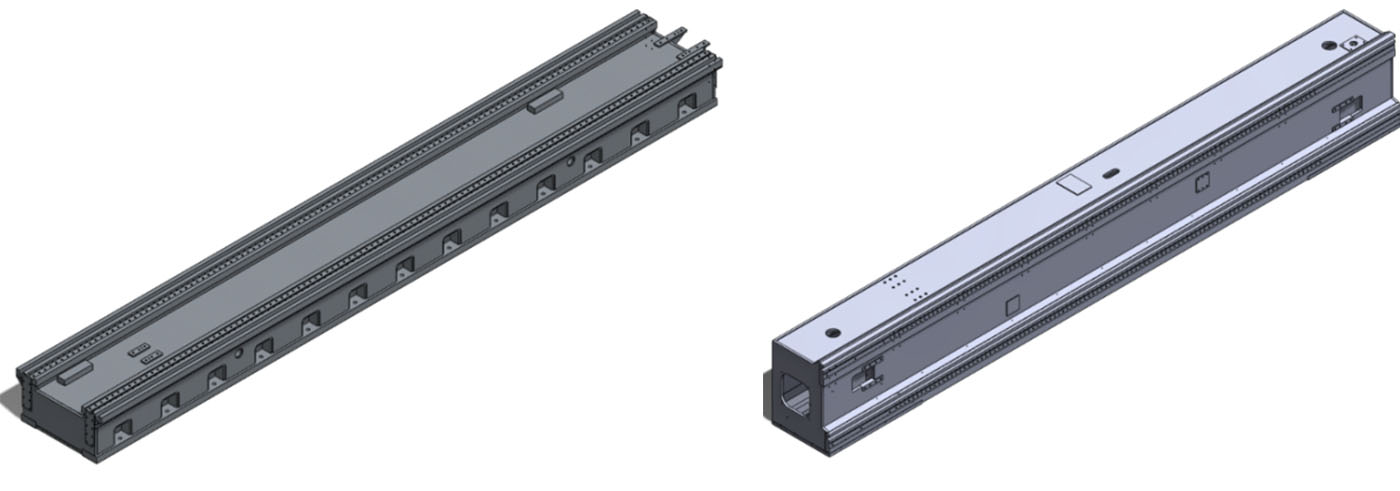

| Chip removal and cooling | Chip conveyor type | Flat chain | |||

| Number of chip conveyor | 2 | ||||

| Chip removal speed | 1m/min | ||||

| Chip conveyor motor power | 2×0.75kW | ||||

| Cooling mode | Internal cooling + external cooling | ||||

| Maximum pressure | 2MPa | ||||

| Maximum flow | 2×50L/min | ||||

| Electrical system | CNC | Siemens 828D | |||

| CNC axis Number | 6 | ||||

| Total motor power | About75kW | ||||

| Overall dimensions of machine tool | Length× Wide × High | About 8m×8m×3m |

About 9m×9m×3m | About 10m×10m×3m | About 10m×10m×3m |

| Total weight of machine tool | About 32t | About 40t | About 48t | ||

Details and advantages

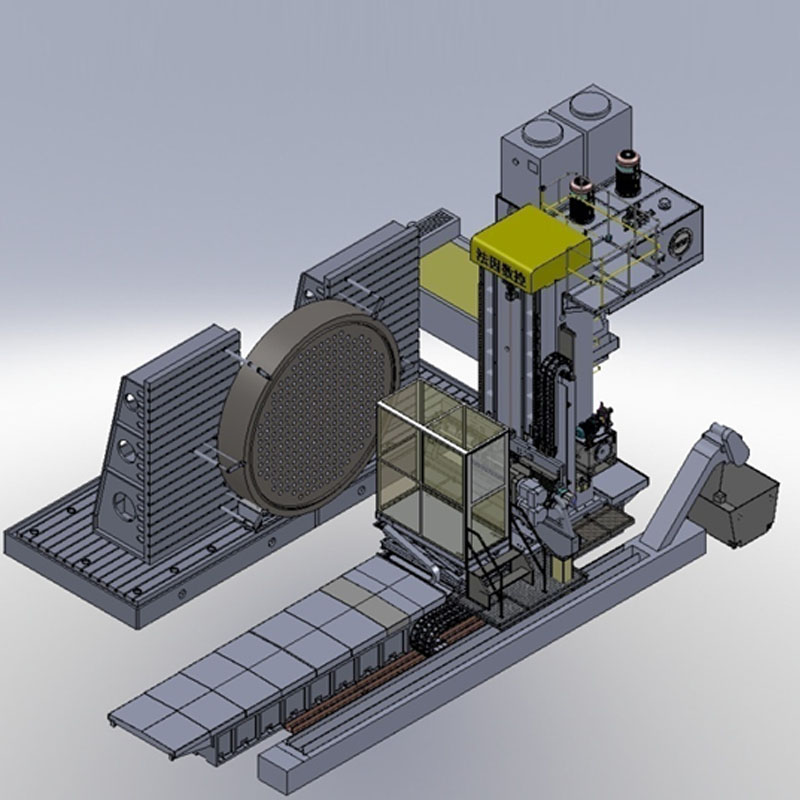

1. This machine is mainly composed of bed and column, beam and horizontal sliding table, vertical ram type drilling power box, worktable, chip conveyor, hydraulic system, pneumatic system, cooling system, centralized lubrication system, electrical system, etc.

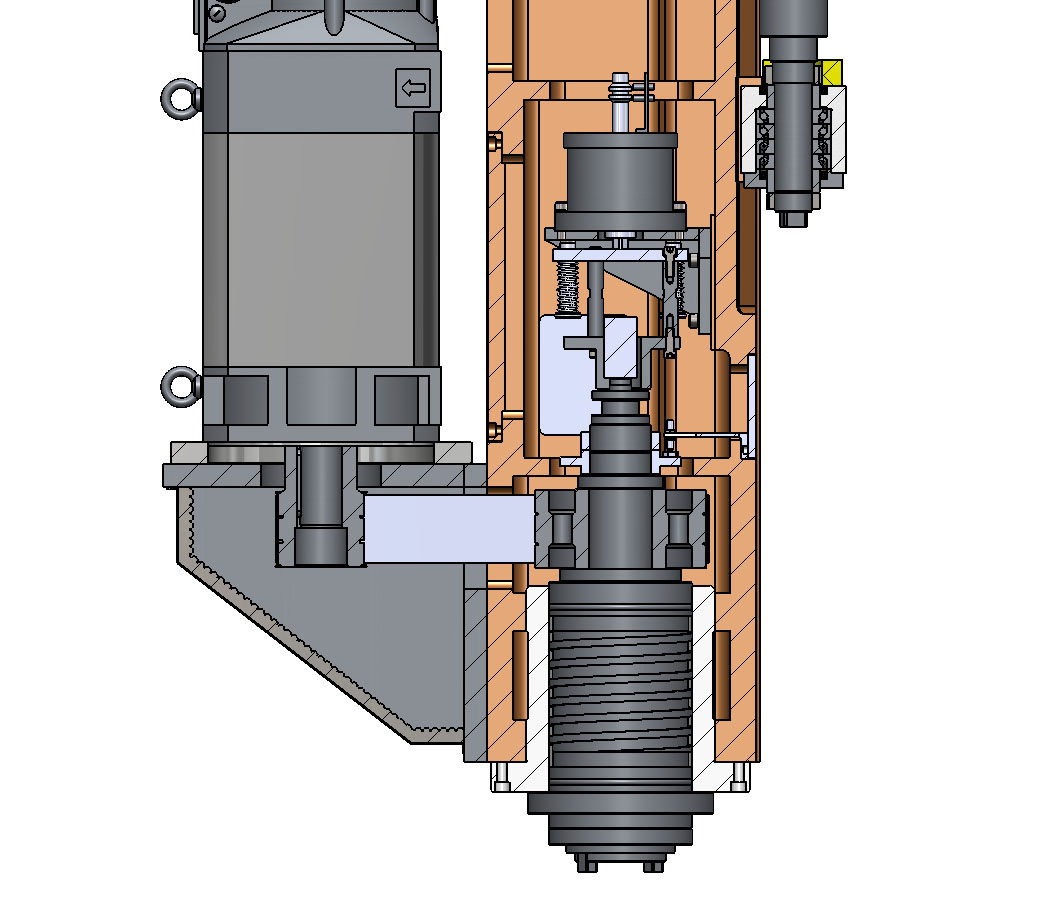

2. High-rigidity bearing base, the bearing adopts high-precision screw special bearing. The extra-long mounting base surface ensures axial rigidity. The bearing is pre-tightened by a lock nut, and the lead screw is pre-tensioned. The stretching amount is determined according to the thermal deformation and elongation of the lead screw to ensure that the positioning accuracy of the lead screw does not change after the temperature rises.

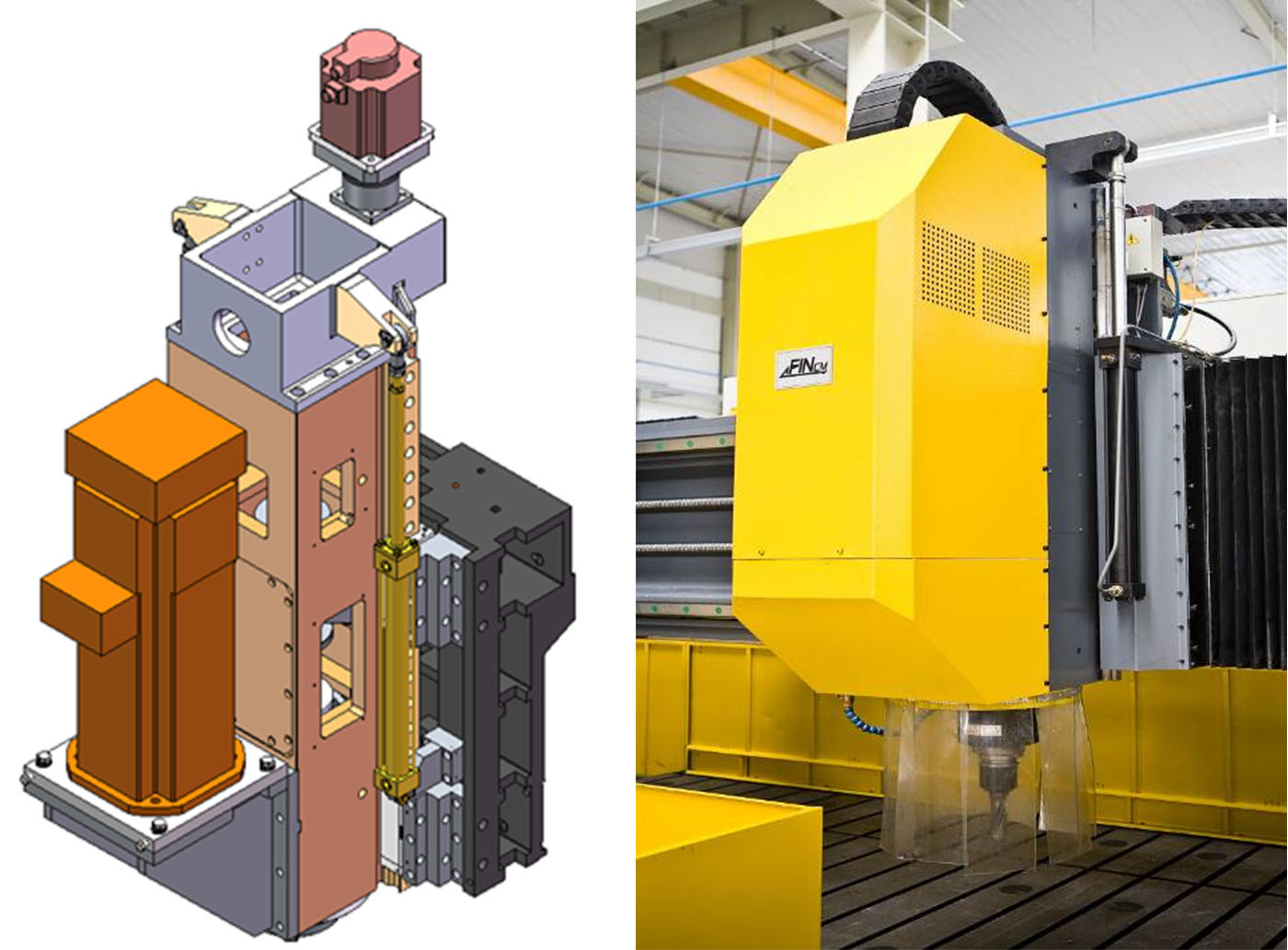

Drilling and milling power head

3. The vertical (Z-axis) movement of the power head is guided by a pair of linear roller guides arranged on the ram, with good guide precision, high vibration resistance and low friction coefficient. The ball screw drive is driven by a servo motor through a precision planetary reducer, which has a high feed force.

4. This machine adopts two flat chain chip conveyors on both sides of the worktable. Iron chips and coolant are collected in the chip conveyor, and the iron chips are transported to the chip conveyor, which is very convenient for chip removal; the coolant is recycled.

5. This machine provides two cooling methods—internal cooling and external cooling, which provide sufficient lubrication and cooling to the tool and material during chip cutting, which better guarantees the drilling quality. The cooling box is equipped with liquid level detection and alarm components, and the standard cooling pressure is 2MPa.

Precision spindle

6. The X-axis guide rails on both sides of the machine are equipped with stainless steel protective covers, and the Y-axis guide rails are equipped with flexible protective covers at both ends.

Chip conveyor

Cooling device

Automatic lubrication device

7. This machine is also equipped with a photoelectric edge finder to facilitate the positioning of circular plate.

Siemens CNC System

Key outsourced components list

|

NO. |

Name |

Brand |

Country |

| 1 |

Linear guide rail |

HIWIN or PMI |

Taiwan, China |

| 2 |

CNC Control System |

Siemens |

Germany |

| 3 |

Servo motor and driver |

Siemens |

Germany |

| 4 |

Precision spindle |

KENTURN or SPINTECH |

Taiwan, China |

| 5 |

Hydraulic valve |

YUKEN OR Justmark |

Japan |

| 6 |

Oil pump |

Justmark |

Taiwan, China |

| 7 |

Automatic lubrication system |

BIJUR OR HERG |

USA or Japan |

| 8 |

Buttons, indicator lights and other main electrical components |

SCHBEIDER/ABB |

France /Germany |

Note: The above is our standard supplier. It’s subject to be replaced by same quality components of other brand if the above supplier can’t supply the components in case of any special matter.

Product detail pictures:

Related Product Guide:

We strive for excellence, services the customers", hopes to be the top cooperation team and dominator business for personnel, suppliers and prospects, realizes benefit share and continual promotion for Best quality Vertical Drilling Machine - PLM Series CNC Gantry mobile drilling machine – FIN CNC , The product will supply to all over the world, such as: Kuwait, Barcelona, Paris, Our items are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our merchandise and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.