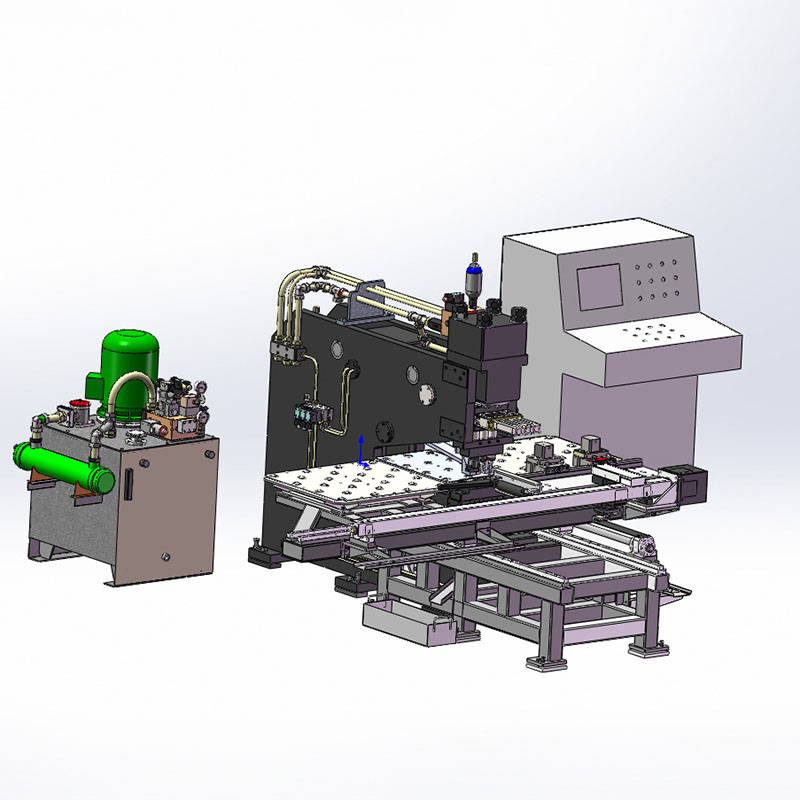

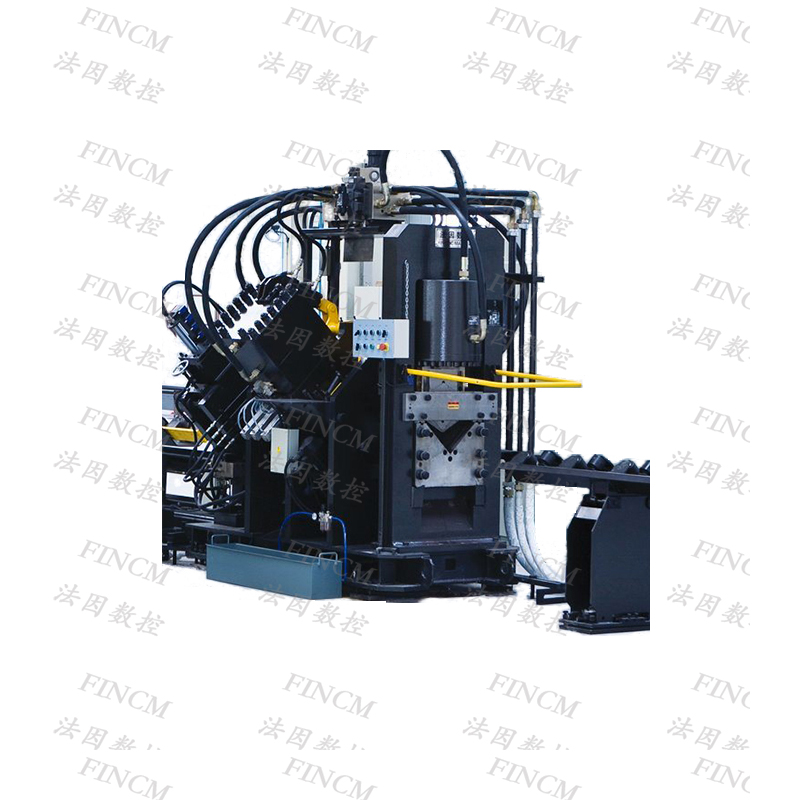

18 Years Factory Band Sawing Machine - CNC Hudraulic Punching and Drilling Machine – FIN CNC

18 Years Factory Band Sawing Machine - CNC Hudraulic Punching and Drilling Machine – FIN CNC Detail:

Product Parameters

| NO. | Item | Parameter | |||||||

| PP(D)103B | PP123 | PPHD123 | PP153 | PPHD153 | |||||

| 1 | Max. punching force | 1000KN | 1200KN | 1500KN | |||||

| 2 | Max. size of plate | 775*1500mm | 800*1500mm | 775*1500mm | 800*1500mm | ||||

| 3 | Thickness of plate | 5-25mm | |||||||

| 4 | Max. punching diameter | φ25.5mm (16Mn, 20mm thickness, Q235, 25mm thickness) |

Φ30mm | ||||||

| 5 | Number of die station | 3 | |||||||

| 6 | Min. distance between hole and plate edge | 25mm | 30mm | ||||||

| 7 | Max. marking force | 800kN | 1000KN | 800KN | 1200KN | ||||

| 8 | Number and Dimension of character | 10 (14*10mm) | 16(14*10mm) | 10 (14×10mm) | |||||

| 9 | Drilling diameter (high-speed steel twist drill) (With drilling function) |

φ16 ~ φ50mm(PPD103B) | φ16 ~ φ40mm | φ16 ~ φ40mm | |||||

| 10 | Rotation speed of drilling spindle(With drilling function) | 120-560r/min(PPD103B)) | 3000r/min | 120-560r/min | |||||

| 11 | Motor power of hydraulic pump | 15KW | 22KW | 15KW | 45KW | ||||

| 12 | The servo motor power of X and Y axes(axes ) | 2*2kw | |||||||

| 13 | The compressed air force ×discharging quantity | 0.5MPa×0.1m3/min | |||||||

| 14 | Overall dimension | 3100*2988*2720mm | 3.6*3.2*2.3m | 3.65*2.7*2.35mm | 3.62*3.72*2.4m | ||||

| 15 | Net weight | About 6500KG | About8200KG | About 9500KG | About12000KG | ||||

Details and advantages

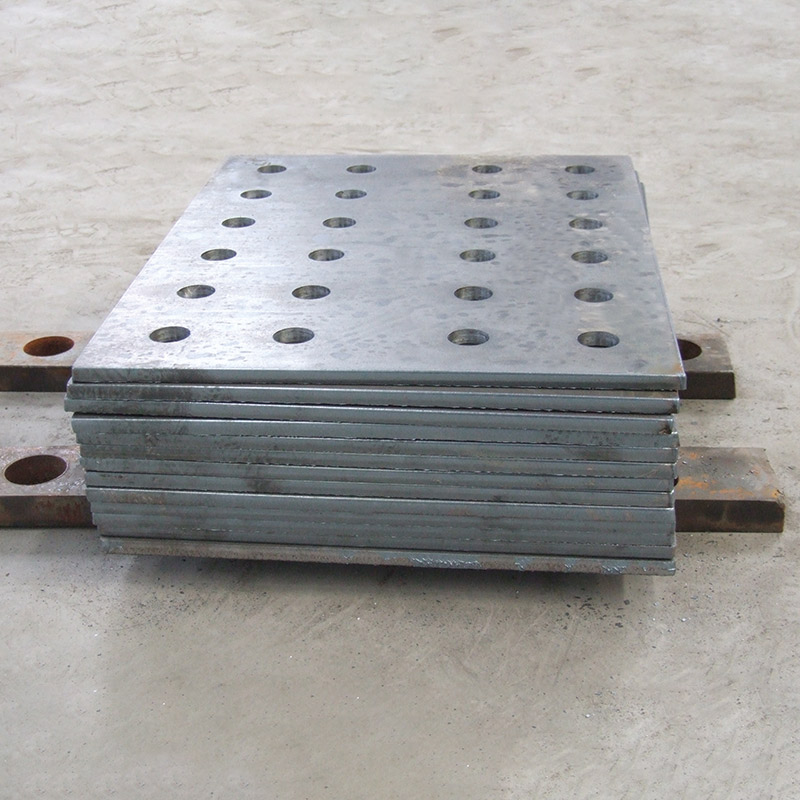

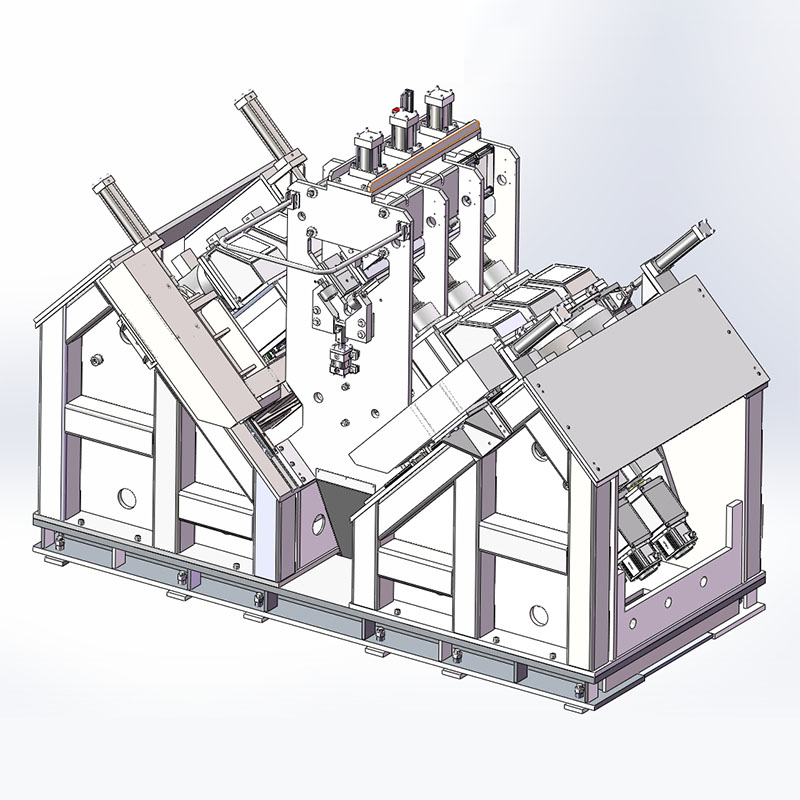

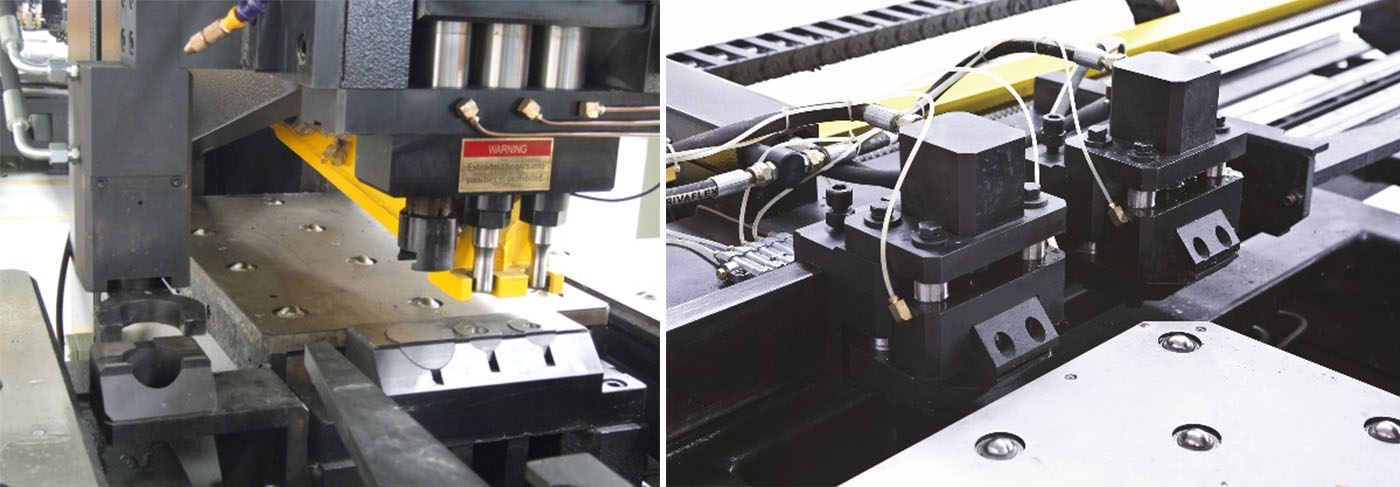

1. With three die positions, three sets of dies can be installed to punch holes of three different diameters on the plate or only two sets of dies and one character box can be installed to punch holes of two different diameters and mar k characters.

Punching die

Hydraulic clamping

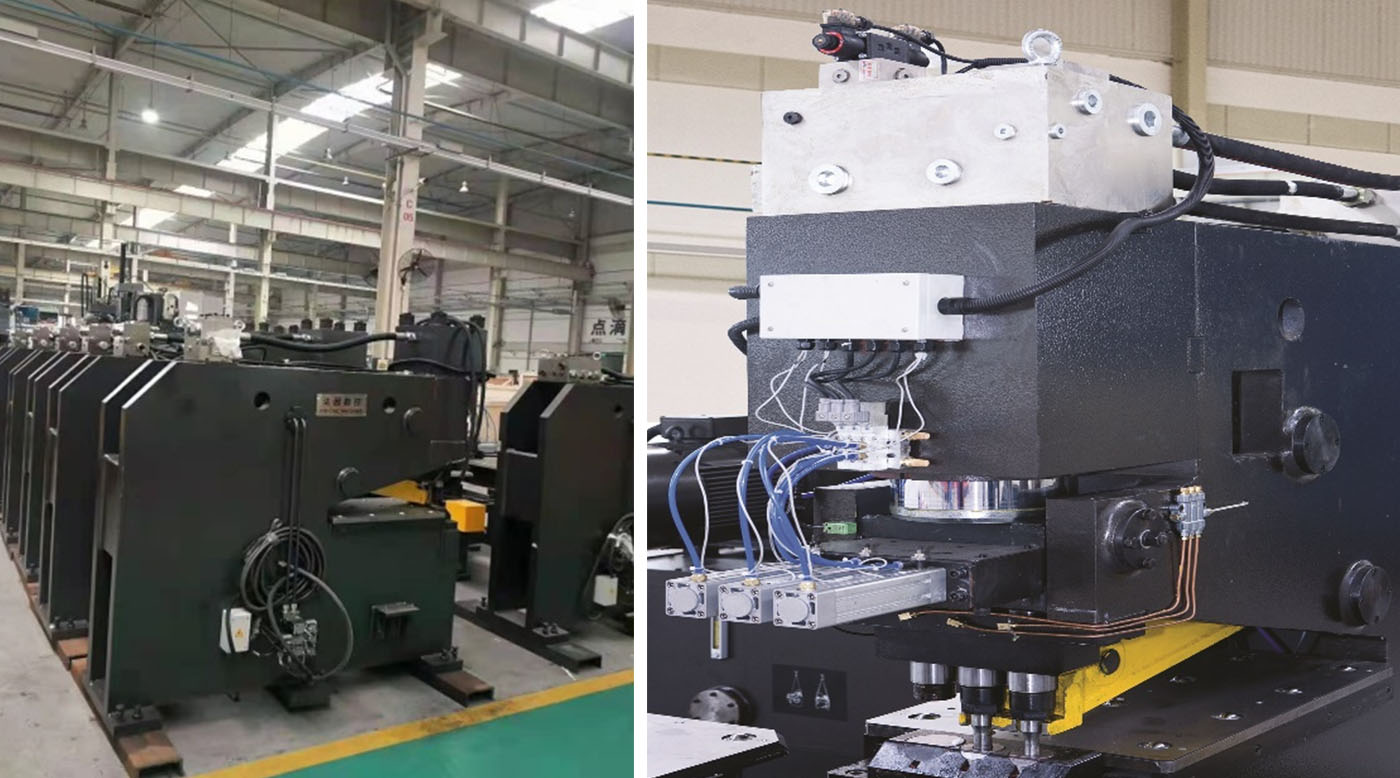

2. The bed of heavy-type machine tool adopts high-quality steel plate welding structure. After welding, the surface is painted, So the surface quality and antirust ability of steel plate are improved.

3. The machine has two CNC axes: x-axis is the left and right movement of the clamp, Y-axis is the front and back movement of the clamp, and the high rigid CNC workbench ensures the reliability and accuracy of feeding.

4. The machine tool is lubricated by the combination of centralized lubrication and decentralized lubrication, so that the machine tool is in good working condition every time.

5. The NC Worktable of moving plate is directly fixed on the foundation, and the worktable is equipped with a universal conveying ball, which has the advantages of small resistance, low noise and easy maintenance.

6. The plate is clamped by two powerful hydraulic clamps, and it can be moved and positioned quickly.

7. The computer adopts English interface, which is easy for general operators to master. It is easy to program.

Key Outsourced Components List

| NO. | Name | Brand | Country |

| 1 | Linear guide rail | HIWIN/PMI | Taiwan(China) |

| 2 | Oil pump | Albert | USA |

| 3 | Electromagnetic relief valve | Atos | Italy |

| 4 | Electromagnetic unloading valve | Atos | Italy |

| 5 | Solenoid valve | Atos | Italy |

| 6 | One way throttle valve | Atos | Italy |

| 7 | P-port throttle valve | JUSTMARK | Taiwan(China) |

| 8 | P port check valve | JUSTMARK | Taiwan(China) |

| 9 | Hydraulic control check valve | JUSTMARK | Taiwan(China) |

| 10 | Drag chain | JFLO | China |

| 11 | Air valve | CKD/SMC | Japan |

| 12 | Confluence | CKD/SMC | Japan |

| 13 | Cylinder | CKD/SMC | Japan |

| 14 | FRL | CKD/SMC | Japan |

| 15 | AC servo motor | Panasonics | Japan |

| 16 | PLC | Mitsubishi | Japan |

Product detail pictures:

Related Product Guide:

We stick to our enterprise spirit of "Quality, Performance, Innovation and Integrity". We purpose to create a lot more price for our prospects with our rich resources, innovative machinery, experienced workers and great products and services for 18 Years Factory Band Sawing Machine - CNC Hudraulic Punching and Drilling Machine – FIN CNC , The product will supply to all over the world, such as: Canada, British, Canberra, We provide good quality but unbeatable low price and the best service. Welcome to post your samples and color ring to us .We will produce the goods according to your request. If you are interested in any products we offer, please feel free to contact us directly by mail, fax, telephone or internet. We are here to answer your questions from Monday to Saturday and looking forward to cooperating with you.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.